Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Cloth Worker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

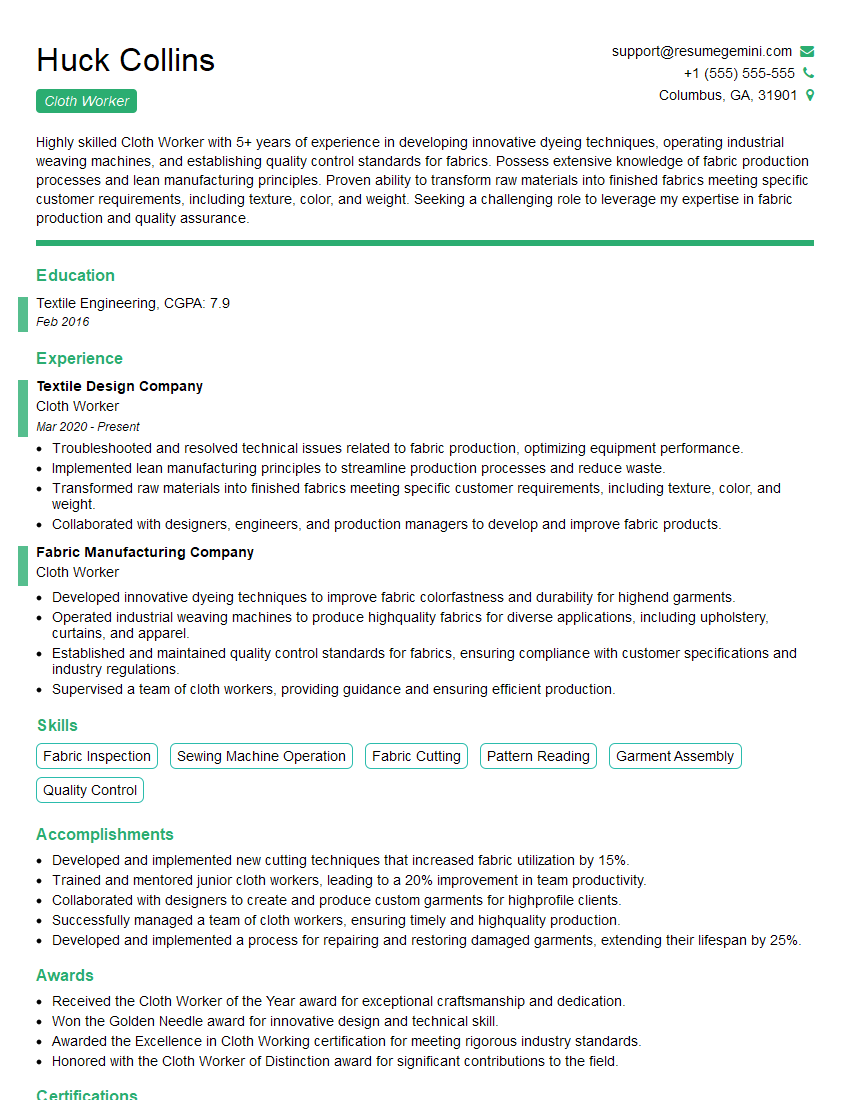

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cloth Worker

1. What are the key steps involved in garment construction?

The key steps involved in garment construction are:

- Pattern making: Creating a paper pattern of the garment based on the design and measurements.

- Cutting: Using the pattern to cut out the fabric pieces for the garment.

- Sewing: Assembling the fabric pieces together using a sewing machine or by hand.

- Finishing: Ironing, pressing, and adding embellishments or details to complete the garment.

2. How do you determine the type of fabric and stitching technique to use for a specific garment?

- Fabric selection: Consider the garment’s intended use, style, and desired drape and feel. Different fabrics, such as cotton, silk, or wool, have unique properties that influence the garment’s appearance and functionality.

- Stitching technique: Choose the appropriate stitch type, needle size, and thread weight based on the fabric’s weight, texture, and seam allowance. Different stitching techniques, such as straight stitch, zigzag stitch, or overlock stitch, serve different purposes and create different seam finishes.

3. What are the different methods of measuring and marking fabrics?

- Measuring tape: Use a flexible tape measure to accurately determine fabric dimensions, such as length, width, and seam allowances.

- Rulers and yardsticks: Rigid rulers or yardsticks provide straight lines for marking seam lines, hems, and other precise measurements.

- Marking tools: Chalk, fabric pencils, or water-soluble markers can be used to transfer markings from patterns or directly onto fabrics.

- Notching and clipping: Small notches or clips can be used to mark specific points or indicate seam lines, especially on curved or bias-cut fabrics.

4. How do you ensure the accuracy and quality of your work?

- Pattern verification: Carefully check patterns for errors and make necessary adjustments to ensure proper fit and construction.

- Precise cutting: Use sharp scissors or a rotary cutter to ensure clean and accurate fabric cuts, minimizing fabric waste and ensuring proper garment fit.

- Correct sewing techniques: Follow established sewing techniques, such as using the proper stitch length and tension, to create strong and durable seams.

- Regular machine maintenance: Keep sewing machines clean, oiled, and in good working order to ensure consistent stitch quality and prevent fabric damage.

5. Describe your experience in working with various types of fabrics and patterns.

- Fabric knowledge: Experience working with different fabric types, such as natural fibers (cotton, silk, wool), synthetic fibers (polyester, nylon, spandex), and blends, and understanding their unique properties and handling requirements.

- Pattern interpretation: Ability to read and interpret sewing patterns, understanding the symbols, measurements, and construction instructions.

- Pattern manipulation: Experience in making adjustments to patterns, such as altering the length, size, or style, to achieve the desired fit and design.

6. How do you handle mistakes or unexpected challenges during garment construction?

- Problem identification: Quickly identify the source of the mistake or challenge, whether it’s a sewing error, fabric defect, or pattern issue.

- Finding solutions: Explore different options to resolve the issue, such as re-cutting fabric, adjusting the sewing technique, or consulting with a supervisor or experienced sewist.

- Learning from mistakes: Analyze the mistake and identify any areas for improvement in future projects to minimize similar errors.

7. What is your understanding of grainlines and how do you ensure proper grain alignment?

- Grainlines: Understanding the direction of the threads in the fabric, which determines the fabric’s stability, drape, and strength.

- Grain alignment: Cutting and sewing fabric pieces with the grainlines aligned ensures the garment hangs and drapes correctly, maintaining its shape and preventing distortion.

- Grain marking: Using tools like grainlines printed on patterns or pulling a thread to identify and align the grainlines before cutting.

8. How do you stay up-to-date on the latest trends and techniques in garment construction?

- Fashion magazines and industry publications: Reading fashion magazines, attending industry events, and subscribing to trade publications to stay informed about current trends and best practices.

- Workshops and classes: Participating in workshops or classes to learn new techniques, explore different fabrics, and enhance skills.

- Online resources and tutorials: Utilizing online platforms, such as sewing blogs, video tutorials, and online courses, to access a wealth of information and resources.

9. Can you describe a project you’re particularly proud of and why?

- Project selection: Choose a garment or project that showcases your skills, creativity, and attention to detail.

- Highlight challenges: Describe any specific challenges you faced during the project and how you overcame them.

- Outcome and satisfaction: Explain why you’re particularly proud of the finished product, emphasizing the skills and effort you invested.

10. What qualities and skills do you possess that make you a suitable candidate for the role of Cloth Worker?

- Technical proficiency: Demonstrated proficiency in all aspects of garment construction, including pattern making, cutting, sewing, and finishing.

- Attention to detail: Meticulous and precise in your work, ensuring garments meet high standards of quality and accuracy.

- Problem-solving abilities: Ability to identify and resolve issues effectively during garment construction, minimizing errors and maintaining efficiency.

- Time management and productivity: Demonstrated ability to manage time effectively, meet deadlines, and maintain a high level of productivity.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cloth Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cloth Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Cloth Worker is responsible for converting raw cloth into finished products such as clothing or home textiles. Key responsibilities include:1. Fabric Preparation

Preparing fabrics by inspecting, measuring, and cutting them to the required size and shape.

2. Sewing and Assembly

Sewing pieces of fabric together to create garments or other textile products, using various sewing machines and techniques.

3. Finishing and Inspection

Inspecting finished products for quality and accuracy, making any necessary repairs or adjustments, and adding finishing touches such as buttons or zippers.

4. Machine Operation and Maintenance

Operating and maintaining sewing machines and other equipment, ensuring they are in good working order and performing efficiently.

Interview Preparation Tips

To ace the interview for a Cloth Worker position, candidates should follow these tips:1. Research the Company and Position

Thoroughly research the company’s website, industry, and products to demonstrate your knowledge and interest in the role.

2. Practice Your Technical Skills

Review your sewing and fabric manipulation techniques, and be prepared to demonstrate your proficiency during the interview.

3. Highlight Your Attention to Detail

Emphasize your ability to work accurately and meticulously, ensuring the quality of finished products.

4. Convey Your Teamwork and Communication Skills

Discuss your experience working in a team environment and your ability to communicate effectively with colleagues.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Cloth Worker role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.