Are you gearing up for an interview for a Clothing Cutter position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Clothing Cutter and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

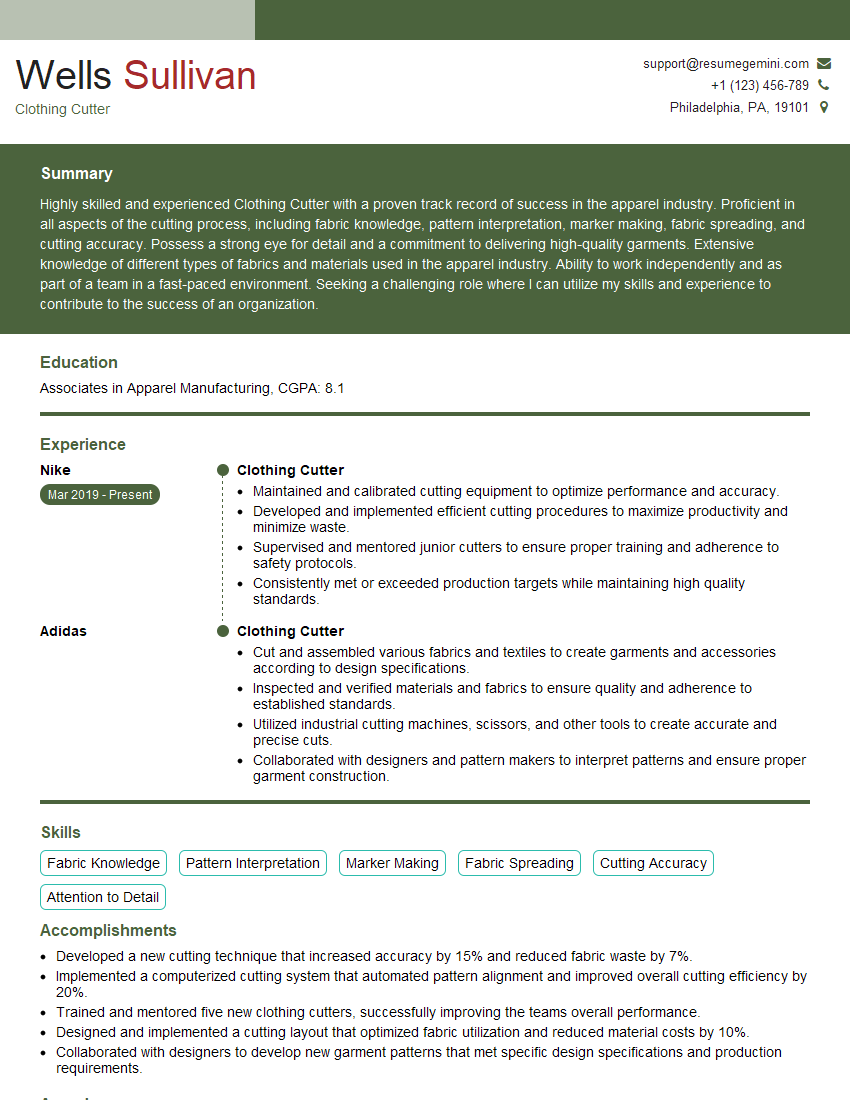

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Clothing Cutter

1. What techniques do you use to ensure accurate cutting of garment pieces?

To ensure accurate cutting of garment pieces, I utilize various techniques:

- Precise Measurement: I meticulously measure and mark the fabric using measuring tapes, rulers, and chalk to maintain exact dimensions.

- Sharp Cutting Tools: I use sharp knives and shears to ensure clean, straight cuts, minimizing fabric fraying and distortions.

- Pattern Matching: I carefully match pattern pieces to ensure correct grain alignment, fabric direction, and seam allowances.

- Grading and Bundling: I grade patterns for different sizes and bundle layers of fabric together to achieve consistent cutting results.

- Quality Control: I systematically inspect cut pieces for accuracy, completeness, and any potential defects before moving on to the next step.

2. What types of fabrics have you worked with and how do you adjust your cutting techniques for different materials?

Understanding Fabric Properties

- I am familiar with a wide range of fabrics, including natural fibers (e.g., cotton, linen, wool), synthetic fibers (e.g., polyester, nylon, spandex), and blends.

- I understand the unique properties of each fabric, such as stretchiness, drape, and fiber content, which influence cutting techniques.

Adjusting Cutting Techniques

- Woven Fabrics: I cut woven fabrics along the straight grain to prevent stretching or distortion.

- Knit Fabrics: I cut knit fabrics with minimal tension to avoid puckering or runs.

- Stretch Fabrics: I use a sharp, rotary cutter to cut stretch fabrics and ensure smooth, clean edges.

- Delicate Fabrics: I handle delicate fabrics with care, using smaller shears and supporting the fabric while cutting.

3. How do you handle complex garment designs with multiple layers and intricate details?

To handle complex garment designs, I follow a systematic approach:

- Pattern Analysis: I thoroughly study the pattern, identifying all layers, details, and construction methods.

- Layer Separation: I separate layers to cut them individually, ensuring precision and avoiding shifting.

- Marking and Notching: I carefully mark and notch fabric pieces to guide seam alignment and ensure accurate construction.

- Interfacing and Trimming: I apply interfacing to areas requiring reinforcement and trim interfacing edges precisely to prevent bulkiness.

- Assembly Planning: I plan the assembly sequence to minimize fabric waste and ensure proper alignment of details.

4. What do you do if you encounter fabric defects during the cutting process?

When fabric defects are encountered, I take the following steps:

- Defect Identification: I carefully inspect the fabric to identify the type and extent of the defect.

- Defect Avoidance: I adjust the cutting plan to avoid using fabric with significant defects, minimizing fabric waste.

- Repair or Replacement: If possible, I repair small defects using fabric glue or thread, or replace the defective fabric.

- Communication: I communicate with supervisors or quality control personnel about major defects that cannot be repaired or avoided.

- Documentation: I document the defect and its handling, including the amount of fabric affected, for accurate record-keeping.

5. How do you maintain a safe and efficient work environment in the cutting room?

Safety Protocols

- I adhere to all established safety regulations, such as wearing proper safety gear and using sharp tools responsibly.

- I keep the cutting area clean and organized, free from tripping hazards and clutter.

- I operate cutting machines safely, following manufacturer guidelines and avoiding distractions.

Efficiency Strategies

- I plan my cutting sequences efficiently to minimize fabric waste and optimize cutting time.

- I use ergonomic techniques to reduce fatigue and increase productivity.

- I maintain my tools and equipment regularly to ensure optimal performance.

6. What quality control measures do you implement to ensure the accuracy and consistency of cut pieces?

To ensure the quality of cut pieces, I implement the following measures:

- Visual Inspection: I visually inspect each cut piece for defects, such as uneven edges, misaligned patterns, or missed notches.

- Dimensional Verification: I use measuring tapes or templates to verify the dimensions of cut pieces against the pattern.

- Seam Allowance Consistency: I check the consistency of seam allowances throughout the garment, ensuring they align when sewing.

- Sample Creation: I cut sample pieces from new fabrics or patterns to test the accuracy of the cutting process before production.

7. How do you handle time-sensitive production deadlines?

To meet time-sensitive deadlines, I employ the following strategies:

- Prioritization: I prioritize urgent orders and allocate resources accordingly.

- Efficient Planning: I carefully plan my cutting sequences and optimize fabric layouts to minimize waste and maximize output.

- Teamwork and Communication: I collaborate with other team members to ensure timely delivery of materials and avoid bottlenecks.

- Overtime and Flexibility: When necessary, I am willing to work overtime or adjust my schedule to meet deadlines.

8. How do you keep up with the latest trends and advancements in clothing cutting technology?

To stay abreast of the latest advancements, I take the following steps:

- Industry Publications: I read trade magazines and attend industry events to stay informed about new technologies and best practices.

- Online Training: I participate in online courses and webinars to enhance my skills and knowledge.

- Equipment Updates: I familiarize myself with new cutting machines and software to improve efficiency and accuracy.

9. What software programs are you proficient in for clothing pattern drafting and cutting?

I am proficient in the following software programs:

- Computer-Aided Design (CAD): I use CAD software to create and modify patterns, generate markers, and optimize fabric layouts.

- Automated Cutting Machines: I am familiar with the operation of automated cutting machines, including CNC (Computer Numerical Control) and laser cutters.

10. How do you stay motivated and focused in a fast-paced production environment?

In a fast-paced production environment, I stay motivated and focused by:

- Goal Setting: I set realistic goals and track my progress to stay accountable and motivated.

- Challenging Tasks: I embrace challenging tasks as opportunities for growth and improvement.

- Positive Mindset: I maintain a positive attitude and focus on the end result, which is producing high-quality garments.

- Team Collaboration: I collaborate with other team members to share knowledge, support each other, and celebrate successes.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Clothing Cutter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Clothing Cutter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Clothing Cutter is responsible for accurately cutting fabric into pieces for clothing production. They work closely with pattern makers and sewers to ensure that the clothing is made to the correct specifications. Some of the key job responsibilities of a Clothing Cutter include:

1. Reading and understanding patterns

Clothing Cutters must be able to read and understand patterns in order to cut the fabric correctly. They need to be able to identify the different symbols and markings on the pattern and to understand how the pieces fit together.

2. Cutting fabric

Clothing Cutters use a variety of tools to cut fabric, including scissors, rotary cutters, and band knives. They need to be able to cut the fabric accurately and cleanly in order to produce high-quality garments.

3. Inspecting fabric and garments

Clothing Cutters are responsible for inspecting fabric and garments for defects. They need to be able to identify and correct any errors in the cutting process.

4. Maintaining equipment

Clothing Cutters are responsible for maintaining their own equipment. They need to be able to clean and oil their machines and to make minor repairs.

Interview Tips

Here are some tips for preparing for an interview for a Clothing Cutter position:

1. Research the company and the position

Before you go to your interview, take some time to research the company and the position you’re applying for. This will help you to understand the company’s culture and the specific requirements of the job.

2. Prepare your answers to common interview questions

There are a number of common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” Take some time to prepare your answers to these questions in advance.

3. Bring a portfolio of your work

If you have any examples of your work, such as garments or patterns that you’ve created, bring them to your interview. This will give the interviewer a chance to see your skills and abilities firsthand.

4. Dress professionally

First impressions matter, so make sure to dress professionally for your interview. This means wearing clean, pressed clothes and avoiding excessive jewelry or makeup.

5. Be confident and enthusiastic

Interviewers are looking for candidates who are confident and enthusiastic about the position. Be sure to make eye contact, speak clearly, and show that you’re passionate about the field.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Clothing Cutter, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Clothing Cutter positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.