Are you gearing up for an interview for a Clutch Mechanic position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Clutch Mechanic and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

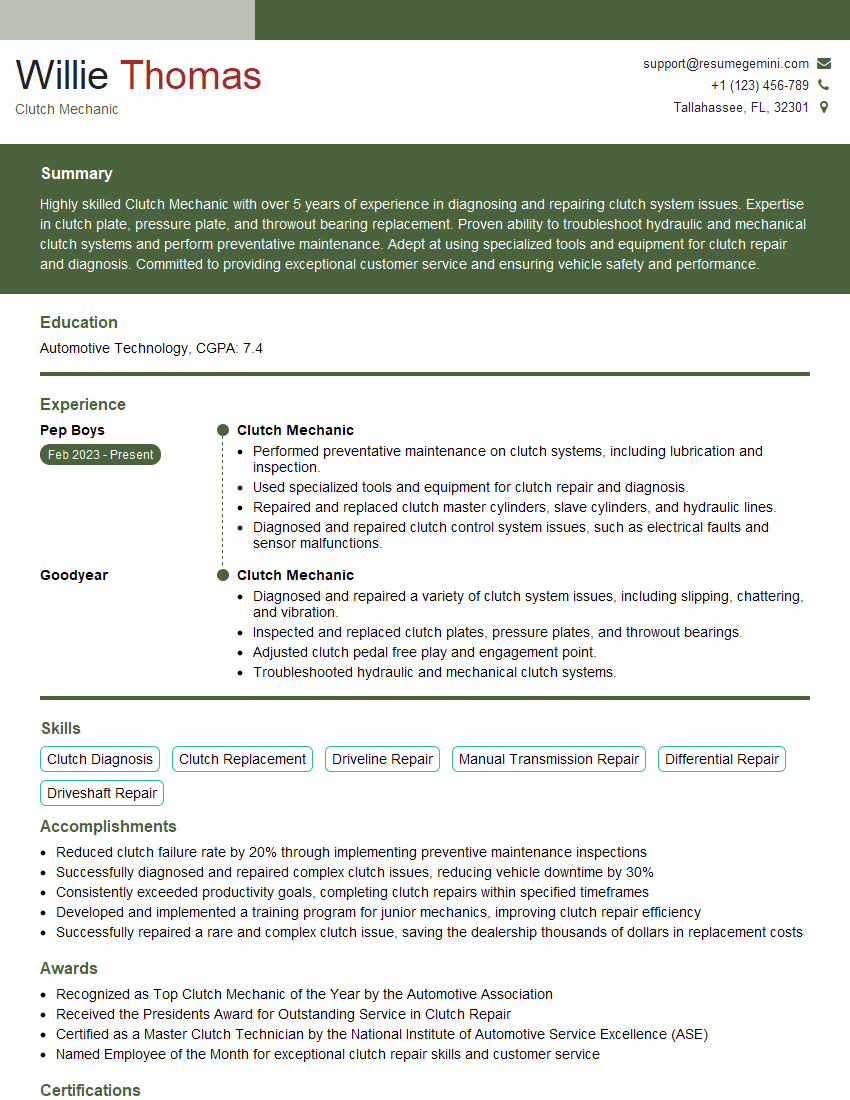

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Clutch Mechanic

1. What are the main components of a clutch system and how do they work together?

The main components of a clutch system are the clutch pedal, clutch master cylinder, clutch slave cylinder, clutch fork, clutch release bearing, and the clutch disc and pressure plate. When the clutch pedal is depressed, the clutch master cylinder sends hydraulic fluid to the clutch slave cylinder. The clutch slave cylinder then pushes the clutch fork, which moves the clutch release bearing. The clutch release bearing presses against the pressure plate, which releases the clutch disc from the flywheel. This allows the transmission to be shifted into a different gear.

2. What are the different types of clutches?

Dry clutch

- A dry clutch is a type of clutch that uses friction to engage and disengage the transmission. Dry clutches are typically used in manual transmission vehicles.

Wet clutch

- A wet clutch is a type of clutch that uses oil to engage and disengage the transmission. Wet clutches are typically used in automatic transmission vehicles.

Centrifugal clutch

- A centrifugal clutch is a type of clutch that uses centrifugal force to engage and disengage the transmission. Centrifugal clutches are typically used in small engines, such as those found on motorcycles and lawnmowers.

3. What are the symptoms of a worn clutch?

- Slipping: A slipping clutch is a clutch that is not able to fully engage the transmission. This can cause the vehicle to lose power or stall.

- Chattering: A chattering clutch is a clutch that makes a noise when it is engaged. This noise is caused by the clutch disc and pressure plate not making full contact with each other.

- Juddering: A juddering clutch is a clutch that causes the vehicle to shudder when it is engaged. This shuddering is caused by the clutch disc and pressure plate not engaging smoothly with each other.

4. What are the steps involved in replacing a clutch?

- Remove the transmission from the vehicle.

- Remove the clutch pressure plate and disc.

- Inspect the flywheel for wear and damage.

- Install the new clutch disc and pressure plate.

- Reinstall the transmission.

- Bleed the clutch hydraulic system.

5. What are some tips for prolonging the life of a clutch?

- Avoid riding the clutch. Riding the clutch is a common habit that can prematurely wear out the clutch.

- Shift smoothly. Shifting smoothly can help to reduce wear on the clutch.

- Use the correct gear. Using the correct gear can help to reduce the amount of stress on the clutch.

- Have the clutch inspected regularly. Having the clutch inspected regularly can help to identify and fix problems early on.

6. What are some common mistakes that people make when replacing a clutch?

- Not using the correct tools. Using the correct tools can help to prevent damage to the clutch and other components.

- Not following the proper procedures. Following the proper procedures can help to ensure that the clutch is installed correctly.

- Not bleeding the clutch hydraulic system. Bleeding the clutch hydraulic system is necessary to remove any air from the system.

7. What are some of the challenges that you have faced as a clutch mechanic?

Some of the challenges that I have faced as a clutch mechanic include:

- Diagnosing clutch problems. Clutch problems can be difficult to diagnose, especially if the symptoms are intermittent.

- Replacing clutches in tight spaces. Clutches are often located in tight spaces, which can make it difficult to remove and install them.

- Working with heavy components. Clutches and transmissions are heavy components, which can make it difficult to handle them.

8. What are some of the latest trends in clutch technology?

Some of the latest trends in clutch technology include:

- The development of new clutch materials. New clutch materials are being developed that are more durable and can withstand higher temperatures.

- The use of electronic controls. Electronic controls are being used to improve the performance and reliability of clutches.

- The development of new clutch designs. New clutch designs are being developed that are more efficient and compact.

9. What are some of the most important qualities of a good clutch mechanic?

Some of the most important qualities of a good clutch mechanic include:

- Attention to detail. Clutch mechanics need to be able to pay attention to detail in order to identify and fix clutch problems.

- Mechanical skills. Clutch mechanics need to have strong mechanical skills in order to remove and install clutches and other components.

- Problem-solving skills. Clutch mechanics need to be able to diagnose and solve clutch problems.

- Customer service skills. Clutch mechanics need to be able to communicate effectively with customers and explain the repairs that are needed.

10. Why are you interested in working as a clutch mechanic?

I am interested in working as a clutch mechanic because I enjoy working with my hands and solving problems. I am also fascinated by the mechanics of vehicles and how they work. I believe that my skills and experience would make me a valuable asset to your team.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Clutch Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Clutch Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Clutch Mechanic is responsible for ensuring the functioning and proper operation of automotive clutches. They perform various tasks related to servicing, maintaining, and repairing clutches and other driveline components.

1. Clutch Inspection and Diagnosis

Inspect and diagnose clutch problems, including slipping, chatter, and vibration.

- Identify worn or damaged clutch components.

- Determine the cause of clutch failure and recommend repairs.

2. Clutch Replacement and Repair

Replace and repair clutch assemblies, including disc, pressure plate, and throw-out bearing.

- Disassemble and reassemble clutch components.

- Resurface or replace flywheel and pressure plate.

3. Driveline Maintenance and Repair

Perform maintenance and repairs on other driveline components, such as transmissions, driveshafts, and differentials.

- Lubricate and adjust driveline components.

- Replace or repair worn or damaged driveline components.

4. Quality Control and Testing

Ensure the quality of clutch repairs by performing test drives and inspections.

- Inspect repaired clutches for proper operation and smoothness.

- Report any issues or concerns to supervisors.

Interview Tips

To ace an interview for a Clutch Mechanic position, it is essential to prepare adequately. Here are some tips and hacks to help you stand out during the interview process:

1. Research the Company and Industry

Before the interview, take time to learn about the automotive industry and the company you are applying to. Familiarize yourself with their products, services, and recent developments.

- Visit the company’s website and social media pages.

- Research industry news and trends.

2. Highlight Your Skills and Experience

Emphasize your technical skills and experience in clutch repair and maintenance. Provide specific examples of your work and how it has benefited previous employers.

- Quantify your accomplishments, using numbers and metrics.

- Be prepared to discuss your knowledge of different clutch types and repair techniques.

3. Showcase Your Problem-Solving Abilities

Clutch Mechanics often encounter unexpected issues during repairs. In the interview, highlight your problem-solving abilities and how you approach challenges.

- Provide examples of complex clutch repairs you have successfully completed.

- Explain your approach to diagnosing and troubleshooting clutch problems.

4. Prepare for Technical Questions

Expect technical questions related to clutch systems and driveline components. Review common clutch terms and concepts, such as clutch engagement points and torque capacity.

- Practice answering questions about clutch operation, types, and repair procedures.

- Be prepared to discuss different clutch materials and their applications.

5. Dress Professionally and Arrive on Time

First impressions matter. Dress professionally for the interview and arrive on time. Your appearance and punctuality will demonstrate your respect for the interviewer and the position.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Clutch Mechanic role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.