Are you gearing up for a career in Clutch Rebuilder? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Clutch Rebuilder and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

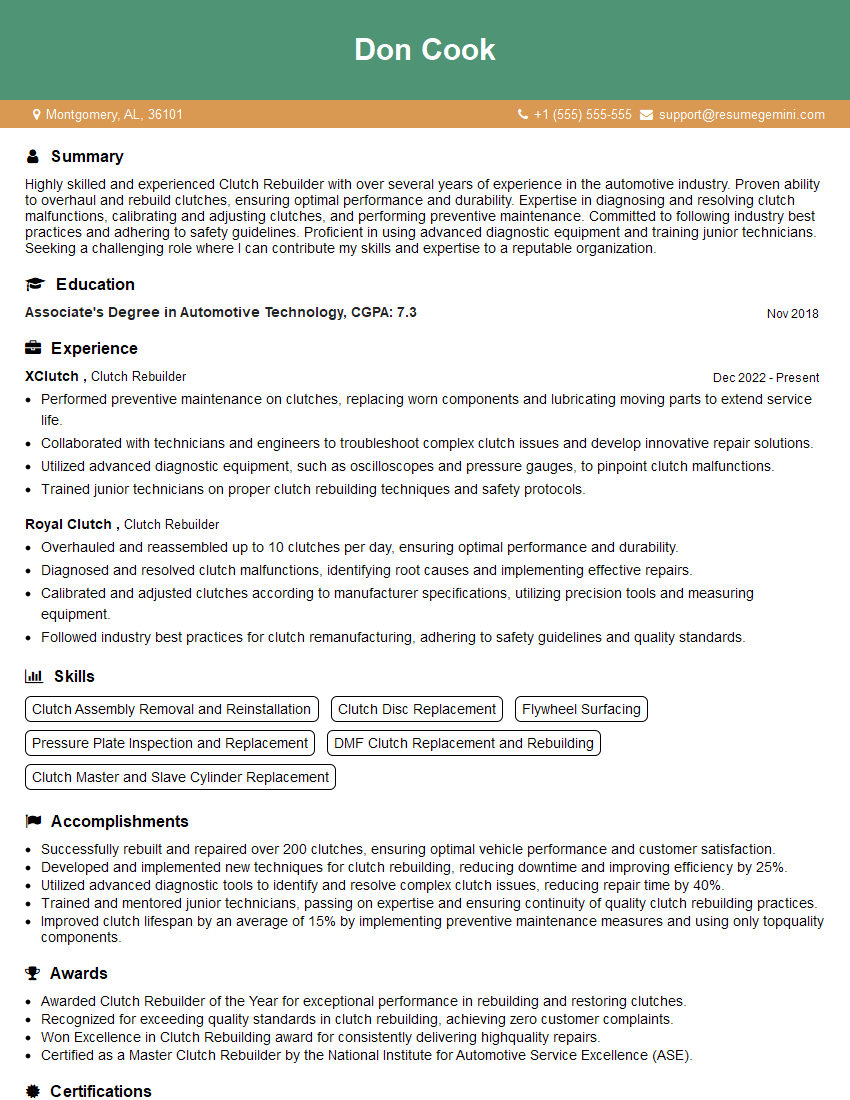

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Clutch Rebuilder

1. What are the common causes of clutch failure?

There are several factors that can contribute to clutch failure, including:

- Wear and tear: The clutch is a friction-based system, and over time, the friction material on the clutch disc can wear down, reducing its ability to engage with the flywheel.

- Heat buildup: Excessive heat can damage the clutch disc and pressure plate, leading to failure. This can occur due to heavy towing, stop-and-go traffic, or slipping the clutch excessively.

- Contamination: Oil or grease on the clutch disc can cause slippage and lead to premature failure.

- Improper installation: Incorrectly installing the clutch can cause misalignment and premature wear.

2. Describe the steps involved in replacing a clutch.

Disassembly:

- Remove the transmission.

- Unbolt the pressure plate and remove the clutch disc.

- Inspect the flywheel for any damage or wear.

Inspection:

- Check the clutch disc for wear, cracks, or contamination.

- Inspect the pressure plate for damage or wear.

- Examine the flywheel for any signs of heat damage or wear.

Reassembly:

- Clean and resurface the flywheel if necessary.

- Install the new clutch disc and pressure plate.

- Tighten the pressure plate bolts to the specified torque.

- Reinstall the transmission.

3. What are the different types of clutches used in vehicles?

- Single-plate clutch: This is the most common type of clutch, consisting of a single friction disc sandwiched between the flywheel and pressure plate.

- Multi-plate clutch: This type of clutch uses multiple friction plates to increase torque capacity.

- Centrifugal clutch: This clutch engages automatically when the engine reaches a certain RPM.

- Hydraulic clutch: A hydraulic clutch uses hydraulic pressure to disengage the clutch, providing smoother operation.

4. How do you diagnose a slipping clutch?

- Engine RPM increases without a corresponding increase in vehicle speed: This indicates that the clutch is not fully engaging, causing the engine to rev higher.

- Burning smell: A burning smell can be a sign of excessive clutch slippage.

- Vehicle shuddering or jerking during acceleration: This can indicate uneven engagement of the clutch disc.

- Difficulty shifting gears: A slipping clutch can make it difficult to engage gears smoothly.

5. What are some tips for prolonging clutch life?

- Avoid excessive slipping: Minimize clutch slippage by engaging the clutch smoothly and avoiding aggressive driving.

- Use the correct gear: Driving in the appropriate gear reduces strain on the clutch.

- Avoid overloading the vehicle: Excessive weight can increase clutch wear.

- Regular maintenance: Inspect the clutch system regularly and replace any worn components as needed.

6. How do you adjust a clutch pedal?

- Check the manufacturer’s specifications: Different vehicles have varying clutch pedal adjustment procedures.

- Locate the clutch pedal adjustment mechanism: This is typically a threaded rod or cable connected to the clutch pedal.

- Adjust the pedal height: The goal is to set the pedal height so that there is about 1 inch of play at the top of the pedal travel.

- Tighten the locknut: Once the pedal height is adjusted, tighten the locknut to secure the setting.

7. What are the safety precautions to consider when working with a clutch?

- Wear safety glasses: Protect your eyes from flying debris.

- Use proper tools: The correct tools ensure safe and efficient disassembly and reassembly.

- Support the transmission: Use a transmission jack or stand to support the transmission during removal and installation.

- Beware of hot surfaces: Allow the engine and exhaust system to cool before working on the clutch.

- Handle heavy components carefully: The clutch and transmission are heavy, so use proper lifting techniques to avoid injury.

8. How do you troubleshoot a clutch that is chattering?

- Inspect the clutch disc: Check for any uneven wear or damage that could cause chattering.

- Examine the pressure plate: Ensure that the pressure plate is flat and free of cracks or damage.

- Check the flywheel: Inspect the flywheel for any signs of heat damage or runout.

- Inspect the clutch release bearing: A worn or damaged release bearing can cause chattering.

- Consider the clutch master and slave cylinders: Air in the hydraulic system or a malfunctioning cylinder can lead to clutch chattering.

9. What are the advantages of using a performance clutch?

- Increased torque capacity: Performance clutches can handle higher torque loads, making them suitable for high-performance vehicles and applications with increased power.

- Improved durability: Performance clutches are designed to withstand extreme conditions and extended use.

- Enhanced engagement: Some performance clutches provide a more aggressive engagement, allowing for quicker acceleration and improved response.

- Increased friction material: Performance clutches often have a greater amount of friction material, resulting in better grip and reduced slippage.

10. Describe the different types of clutch fluids used in vehicles.

- DOT 3: This is a common type of clutch fluid that meets the minimum specifications for most vehicles.

- DOT 4: This fluid has a higher boiling point and is recommended for vehicles with high-performance clutches or those operating in extreme conditions.

- DOT 5: This fluid is silicone-based and does not absorb moisture, making it ideal for vehicles that are not used frequently.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Clutch Rebuilder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Clutch Rebuilder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Clutch Rebuilder is responsible for maintaining and repairing clutches in automobiles and other vehicles.

1. Diagnose and troubleshoot clutch problems

Identify and resolve issues with clutches, including slipping, chattering, and engagement problems.

2. Replace and repair clutch components

Replace worn or damaged clutch components, such as pressure plates, friction discs, and release bearings.

3. Inspect and test clutch systems

Check clutch systems for proper operation and identify potential problems before they become major issues.

4. Maintain and service clutch systems

Lubricate and adjust clutch systems to ensure smooth and efficient operation.

Interview Tips

Prepare for your interview by researching the company, the position, and the automotive industry. This will help you understand the company’s culture, the job requirements, and the industry trends.

1. Research the company and the position

Visit the company’s website, read about their products and services, and learn about their company culture.

Review the job description carefully and make a list of the skills and qualifications that the employer is looking for.

2. Practice answering common interview questions

There are some common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”.

Practice answering these questions in a clear and concise manner.

3. Highlight your skills and experience

In your interview, be sure to highlight the skills and experience that make you the best candidate for the position.

Give specific examples of your accomplishments and how they have benefited your previous employers.

4. Be prepared to talk about your career goals

Employers want to know that you are ambitious and that you are looking for a career with growth potential.

Be prepared to talk about your career goals and how the position fits into your long-term plans.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Clutch Rebuilder role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.