Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted CNC Cutting Operator (Computer Numerical Control Cutting Operator) position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

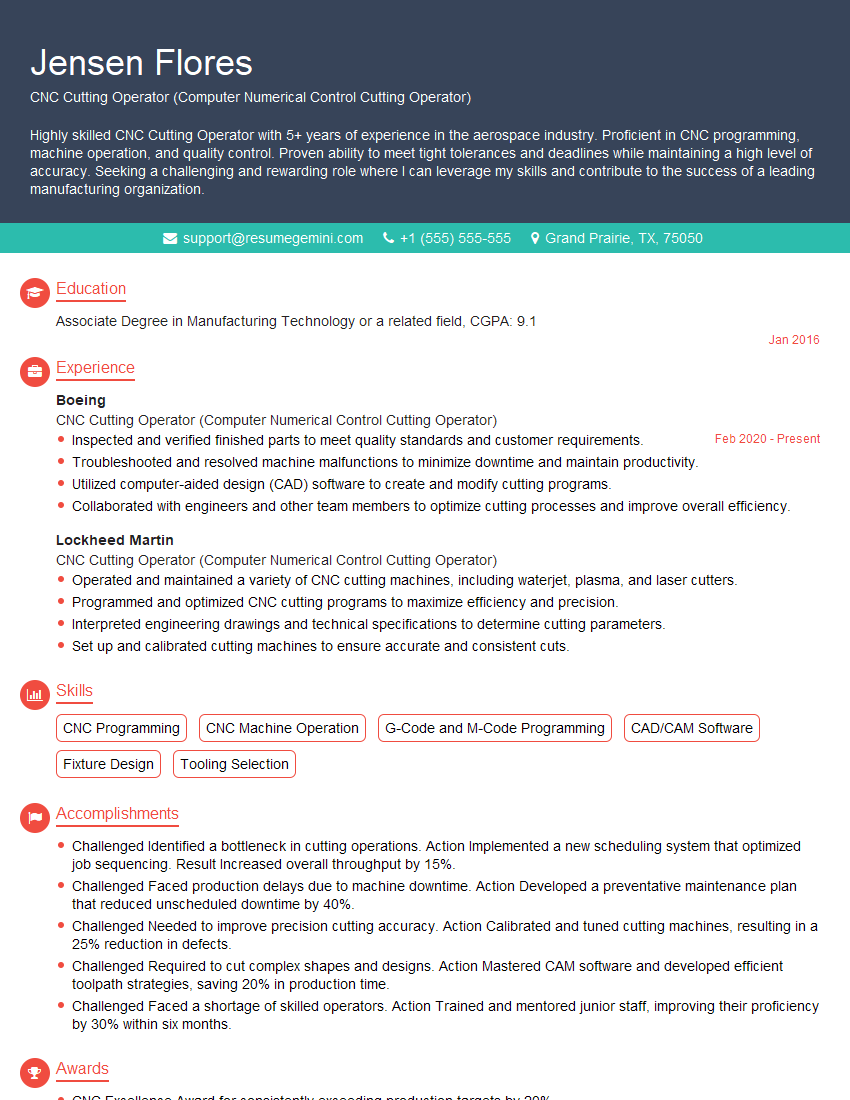

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For CNC Cutting Operator (Computer Numerical Control Cutting Operator)

1. Explain the process of setting up and operating a CNC cutting machine?

Here are the steps involved in setting up and operating a CNC cutting machine:

- Loading the material to be cut onto the machine bed

- Securing the material in place

- Selecting the appropriate cutting tool and installing it in the machine

- Creating or loading the cutting program into the machine’s controller

- Setting the cutting parameters, such as speed, feed, and depth of cut

- Starting the cutting process and monitoring its progress

- Removing the finished part from the machine

2. Describe the different types of cutting operations that can be performed on a CNC cutting machine?

Milling

- Milling is a cutting process that uses a rotating tool to remove material from a workpiece.

- Milling can be used to create a variety of features on a workpiece, such as flat surfaces, holes, and slots.

Turning

- Turning is a cutting process that uses a rotating workpiece and a stationary cutting tool to remove material from the workpiece.

- Turning can be used to create a variety of features on a workpiece, such as cylindrical surfaces, tapered surfaces, and threads.

Drilling

- Drilling is a cutting process that uses a rotating tool to create holes in a workpiece.

- Drilling can be used to create a variety of holes, such as through-holes, blind holes, and tapped holes.

3. What are the safety precautions that must be taken when operating a CNC cutting machine?

Here are some of the safety precautions that must be taken when operating a CNC cutting machine:

- Always wear appropriate safety gear, such as safety glasses, earplugs, and gloves.

- Never operate a CNC cutting machine while under the influence of drugs or alcohol.

- Be aware of the moving parts of the machine and keep your hands and body away from them.

- Never attempt to clean or adjust the machine while it is running.

- Always follow the manufacturer’s instructions for operating the machine.

4. What are the different types of CNC cutting machines?

There are many different types of CNC cutting machines, each with its own unique capabilities.

- Vertical machining centers

- Horizontal machining centers

- Turning centers

- Drilling machines

- Water jet cutters

- Laser cutters

- Plasma cutters

The type of CNC cutting machine that is best for a particular job will depend on the material being cut, the desired accuracy and finish, and the production volume.

5. What are the advantages of using a CNC cutting machine?

There are many advantages to using a CNC cutting machine, including:

- Increased accuracy and repeatability

- Improved surface finish

- Reduced setup time

- Increased productivity

- Reduced labor costs

CNC cutting machines are a valuable asset to any manufacturing operation.

6. What are the challenges of operating a CNC cutting machine?

There are some challenges associated with operating a CNC cutting machine, including:

- The high cost of the machine

- The need for skilled operators

- The complexity of the programming

- The potential for errors

However, the benefits of using a CNC cutting machine outweigh the challenges.

7. What is G-code?

G-code is a programming language used to control CNC machines.

- G-code programs are made up of a series of commands that tell the machine what to do.

- G-code commands can be used to control the machine’s movement, speed, and other functions.

- G-code is a powerful language that can be used to create complex cutting programs.

8. What are the different types of cutting tools that can be used on a CNC cutting machine?

There are many different types of cutting tools that can be used on a CNC cutting machine, including:

- End mills

- Drill bits

- Taps

- Reaming tools

- Boring bars

- Knurling tools

The type of cutting tool that is used will depend on the material being cut and the desired finish.

9. How do you maintain a CNC cutting machine?

CNC cutting machines require regular maintenance to keep them running properly.

- Some of the maintenance tasks that need to be performed include:

- Cleaning the machine

- Lubricating the moving parts

- Inspecting the cutting tools

- Calibrating the machine

Regular maintenance will help to extend the life of the machine and ensure that it produces high-quality parts.

10. What are the troubleshooting tips for CNC cutting machines?

There are a number of things that can go wrong with a CNC cutting machine.

- Some of the most common troubleshooting tips include:

- Checking the power supply

- Checking the fuses

- Checking the cutting tools

- Checking the G-code program

- Recalibrating the machine

If you are unable to troubleshoot the problem yourself, you should contact the machine manufacturer for assistance.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for CNC Cutting Operator (Computer Numerical Control Cutting Operator).

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the CNC Cutting Operator (Computer Numerical Control Cutting Operator)‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

CNC Cutting Operators play a vital role in the manufacturing industry, operating computerized machines to cut various materials with precision. To succeed in this role, candidates must possess a combination of technical expertise, operational skills, and attention to detail.1. CNC Machine Operation and Programming

CNC Cutting Operators are responsible for the safe and efficient operation of CNC cutting machines, including:

- Loading and unloading raw materials

- Setting up and programming the machine using CAD/CAM software

- Monitoring and adjusting machine parameters during operation

- Troubleshooting and resolving any technical issues

2. Quality Control and Inspection

Ensuring the quality of cut parts is crucial. Operators perform regular inspections throughout the cutting process to identify any defects or deviations from specifications.

- Conducting dimensional checks using measuring tools

- Verifying part tolerances and surface finishes

- Maintaining quality records and reporting any discrepancies

3. Material Handling and Inventory Management

CNC Cutting Operators are often responsible for handling and managing raw materials and finished parts.

- Maintaining inventory of raw materials and cut parts

- Ensuring proper storage and handling of materials

- Coordinating with other departments for material replenishment

- Adhering to safety protocols when handling heavy materials

4. Maintenance and Calibration

Regular maintenance and calibration are essential to ensure optimal performance and prevent machine downtime.

- Performing routine inspections and cleaning of the machine

- Conducting preventive maintenance tasks as per manufacturer’s guidelines

- Calibrating and adjusting the machine to maintain accuracy and precision

- Troubleshooting and resolving minor mechanical issues

Interview Tips

To ace the interview for a CNC Cutting Operator position, candidates should focus on highlighting their technical skills, practical experience, and commitment to quality.

1. Research and Preparation

Before the interview, thoroughly research the company, the industry, and the specific role. This demonstrates your interest and enthusiasm.

- Review the job description and identify key responsibilities

- Familiarize yourself with different types of CNC cutting machines and software

- Find examples of your previous work that showcase your skills and experience

2. Emphasize Practical Experience

CNC Cutting Operators should highlight their hands-on experience in operating and programming CNC machines. Quantify your accomplishments and provide specific examples.

- Describe the types of materials and cutting processes you have worked with

- Share examples of how you have optimized machine settings to improve efficiency

- Discuss your role in maintaining and troubleshooting CNC machines

3. Quality and Accuracy

Stress your commitment to quality and accuracy in your work. Explain how you ensure that cut parts meet specifications and customer requirements.

- Describe your understanding of quality control processes and inspection techniques

- Share examples of how you have identified and resolved quality issues

- Emphasize your attention to detail and ability to produce high-quality parts consistently

4. Teamwork and Communication

CNC Cutting Operators often work as part of a team and interact with other departments. Highlight your teamwork and communication skills.

- Describe how you have collaborated with colleagues to improve processes

- Share examples of your ability to communicate effectively with supervisors and customers

- Explain how you stay informed about industry best practices and new technologies

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the CNC Cutting Operator (Computer Numerical Control Cutting Operator) interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!