Are you gearing up for an interview for a CNC Machine Operator (Computer Numerically Controlled Machine Operator) position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for CNC Machine Operator (Computer Numerically Controlled Machine Operator) and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

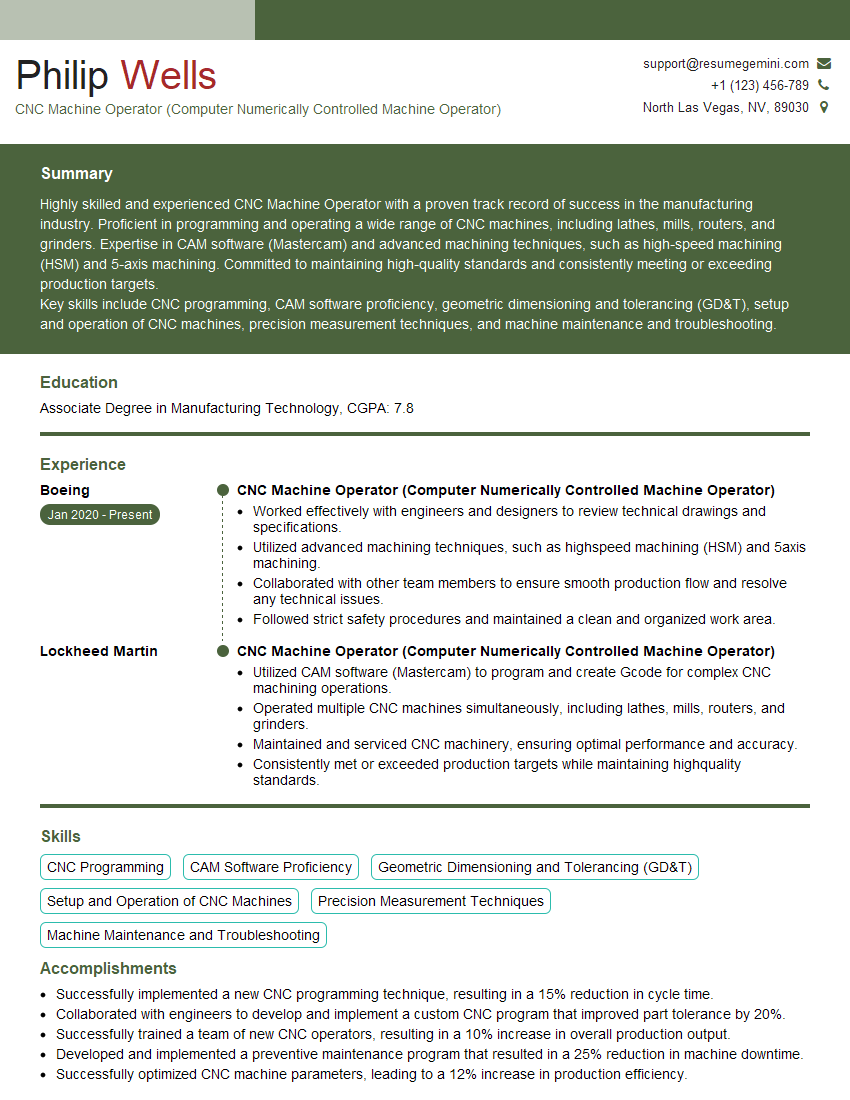

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For CNC Machine Operator (Computer Numerically Controlled Machine Operator)

1. How do you choose the appropriate cutting tools for a specific CNC machining job?

To choose the appropriate cutting tools for a specific CNC machining job, I consider several factors:

- Material: The type of material being machined will dictate the hardness and geometry of the cutting tool.

- Operation: The specific machining operation (e.g., turning, milling) determines the type of cutting tool required.

- Accuracy and finish: The desired accuracy and surface finish of the machined workpiece influence the choice of cutting tool.

- Machine capabilities: The capabilities of the CNC machine, such as spindle speed and power, must be compatible with the selected cutting tool.

2. Describe the process of setting up a CNC machine for a new job.

Job preparation:

- Review the job specifications and create a CNC program.

- Select and mount the appropriate cutting tools.

Machine setup:

- Secure the workpiece in the machine’s fixture.

- Set the machine’s origin and work coordinates.

- Calibrate the cutting tools.

- Load and run the CNC program.

Verification and optimization:

- Inspect the first part to ensure accuracy.

- Make necessary adjustments to the CNC program or machine setup to optimize efficiency and quality.

3. What are the different types of CNC control systems and their applications?

There are several types of CNC control systems, each with its applications:

- Open-loop control: Simple and cost-effective, but less accurate.

- Closed-loop control: Monitors the actual position of the machine and adjusts accordingly, improving accuracy.

- Adaptive control: Adjusts the cutting parameters based on real-time sensor data, optimizing performance.

- Motion control: Controls the movement of the machine’s axes precisely.

- Programmable logic controller (PLC): Controls the machine’s logic and sequences.

4. How do you troubleshoot and resolve common CNC machining problems?

To troubleshoot and resolve common CNC machining problems, I follow a systematic approach:

- Identify symptoms: Observe the machine’s behavior and identify any irregularities.

- Check for errors: Examine the CNC program and machine settings for any errors.

- Inspect hardware: Check the machine’s components, such as cutting tools, for any damage or wear.

- Diagnose the cause: Analyze the symptoms, check for errors, and inspect hardware to determine the root cause.

- Resolve the issue: Implement the appropriate corrective actions, such as repairing or replacing components, adjusting settings, or modifying the CNC program.

5. Describe the different types of CNC programming languages and their usage.

There are several CNC programming languages, each with its applications:

- G-code: Widely used for controlling the movement and operation of CNC machines.

- APT: High-level language designed for complex tool paths and geometric shapes.

- CAM: A higher-level programming language used to create CNC programs from CAD models.

- Conversational programming: User-friendly language that simplifies CNC programming for beginners.

6. How do you ensure the accuracy and quality of machined parts?

To ensure the accuracy and quality of machined parts, I implement several measures:

- Precise setup: Calibrate the machine and cutting tools accurately.

- Proper tooling: Select and use appropriate cutting tools for the job.

- Quality materials: Use high-quality materials that meet the required specifications.

- Regular inspection: Inspect the parts regularly during the machining process.

- Post-processing: Perform any necessary post-processing operations, such as heat treatment or finishing.

7. How do you handle complex CNC machining jobs that require multiple setups?

To handle complex CNC machining jobs that require multiple setups, I follow a meticulous approach:

- Planning: Create a detailed setup plan that outlines the sequence of operations and required fixtures.

- Precision alignment: Ensure precise alignment of the workpiece and fixtures between setups.

- Coordinate systems: Establish and maintain consistent coordinate systems throughout all setups.

- Tooling management: Organize and manage the cutting tools efficiently to minimize tool changes.

- Communication: Communicate the setup plan and any changes clearly to all team members involved.

8. How do you stay up-to-date with the latest CNC machining technologies and advancements?

To stay up-to-date with the latest CNC machining technologies and advancements, I:

- Attend industry events: Participate in conferences, workshops, and exhibitions to learn about new trends.

- Read technical literature: Regularly review trade magazines, journals, and online resources for updates.

- Training and certification: Pursue additional training and certifications to enhance my skills and knowledge.

- Network with experts: Connect with other CNC professionals and exchange ideas.

- Participate in research: Engage in research and development projects to explore new technologies and improve existing processes.

9. How do you prioritize safety when operating CNC machines?

Safety is my top priority when operating CNC machines. I adhere to the following practices:

- Proper training: Undergo thorough training and certification to operate CNC machines safely.

- PPE: Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and earplugs.

- Machine guarding: Ensure that all machine guards are in place and functional.

- Regular inspections: Conduct regular inspections of the machine and its components to identify potential hazards.

- Emergency stop: Familiarize myself with emergency stop procedures and practice them regularly.

10. Describe a challenging CNC machining project you worked on and how you overcame the difficulties.

In a previous role, I was tasked with machining a complex medical implant with tight tolerances. The challenges included:

- Precise dimensions: The implant required precise dimensions and a high surface finish.

- Material hardness: The implant was made of a hard and brittle material that required special cutting tools.

- Multiple setups: The implant required multiple setups and careful alignment to maintain accuracy.

I overcame these challenges by:

- Careful planning: I created a detailed plan for the machining process, considering tool selection, setups, and inspection points.

- Specialized tooling: I used specialized cutting tools designed for machining hard and brittle materials.

- Precise alignment: I implemented precise alignment techniques to ensure accuracy across setups.

- Rigorous inspection: I performed rigorous inspections at each stage of the process to ensure compliance with specifications.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for CNC Machine Operator (Computer Numerically Controlled Machine Operator).

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the CNC Machine Operator (Computer Numerically Controlled Machine Operator)‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

CNC Machine Operators are responsible for operating Computer Numerically Controlled (CNC) machines to manufacture complex parts and components according to specified design and quality standards.

1. Machine Operation and Programming

Set up, operate, and maintain CNC machines (e.g., mills, lathes, routers, grinders) to produce precision parts.

- Interpret technical drawings, blueprints, and work orders to determine machining parameters.

- Load and secure raw materials into the machine and ensure proper alignment.

- Program CNC machines using computer-assisted design (CAD) software or manual input to create machining instructions.

2. Quality Control and Inspection

Conduct quality checks throughout the machining process to ensure parts meet specifications.

- Inspect finished parts using measuring tools, gauges, and other quality control devices.

- Identify and troubleshoot any deviations from specifications and take corrective action.

- Maintain records of inspections and ensure adherence to quality standards.

3. Maintenance and Troubleshooting

Perform routine maintenance and troubleshooting on CNC machines to ensure optimal performance.

- Lubricate and clean machine components regularly.

- Identify and resolve minor malfunctions and adjust settings as needed.

- Alert supervisors to major maintenance issues that require specialized attention.

4. Safety and Compliance

Adhere to safety protocols and comply with regulations related to CNC machine operation.

- Follow safety procedures for machine operation, including proper use of personal protective equipment.

- Ensure that the work area is clean and free of hazards.

- Participate in safety training and maintain updated certifications.

Interview Tips

Here are some tips to help you ace your CNC Machine Operator interview:

1. Research the Company and Industry

Before the interview, take the time to learn about the company and its industry. This will help you understand their needs and how your skills and experience can benefit them.

- Visit the company’s website to learn about their products, services, and values.

- Read articles and industry news to stay up-to-date on the latest trends and technologies.

2. Highlight Your Skills and Experience

During the interview, be sure to highlight your relevant skills and experience. Quantify your accomplishments whenever possible to demonstrate your value.

- Discuss your experience in operating and programming CNC machines.

- Provide examples of your quality control and inspection techniques.

- Share your knowledge of CNC machine maintenance and troubleshooting.

3. Demonstrate Your Passion for CNC Machining

CNC Machine Operators are passionate about their work. Show the interviewer that you are enthusiastic about this field and eager to learn and grow.

- Talk about your interest in CNC machining and how you have pursued this interest outside of work.

- Discuss any projects or hobbies that have allowed you to develop your CNC skills.

4. Ask Thoughtful Questions

At the end of the interview, be sure to ask the interviewer questions. This shows that you are interested in the position and the company.

- Ask about the company’s growth plans and how your skills can contribute to them.

- Inquire about the training and development opportunities available.

- Ask about the company’s safety culture and how they ensure the well-being of their employees.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the CNC Machine Operator (Computer Numerically Controlled Machine Operator) interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!