Are you gearing up for an interview for a CNC Machine Operator (Computerized Numerical Control Machine Operator) position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for CNC Machine Operator (Computerized Numerical Control Machine Operator) and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

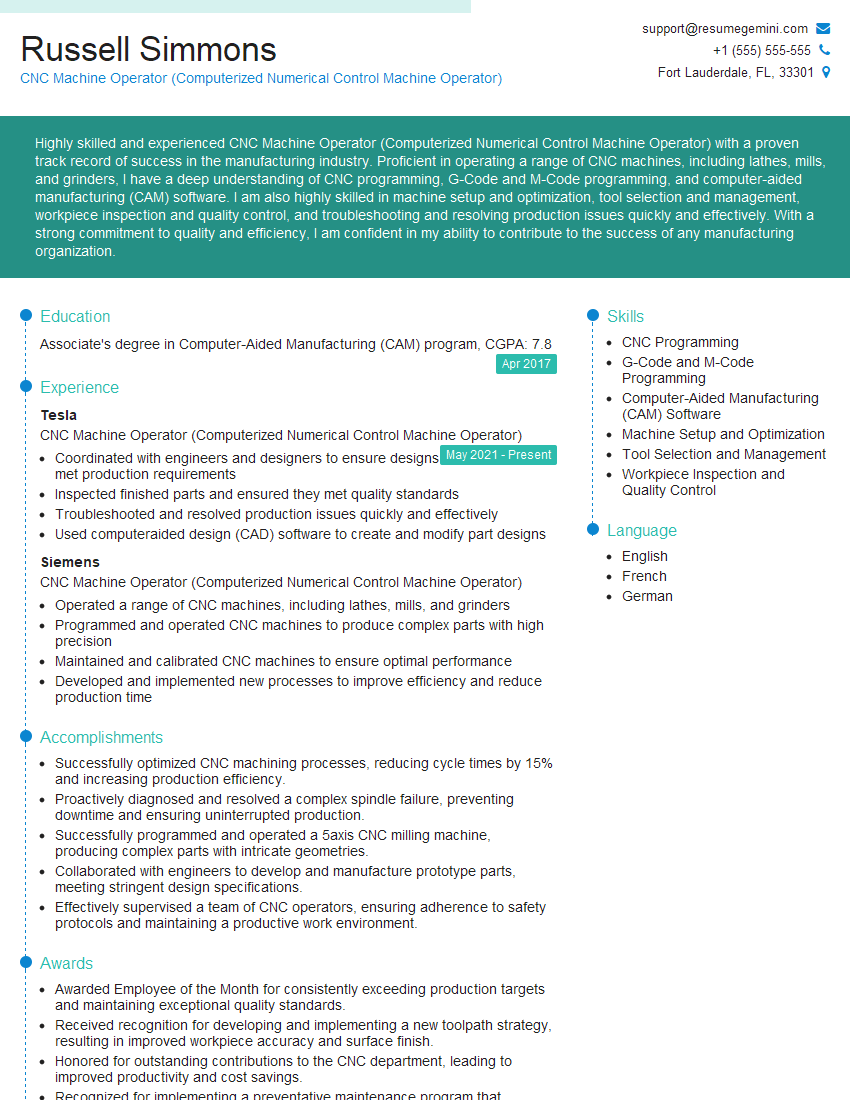

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For CNC Machine Operator (Computerized Numerical Control Machine Operator)

1. What is the difference between absolute and incremental programming in CNC machining?

Absolute programming specifies the exact position of the tool in relation to the machine’s zero point, while incremental programming specifies the movement of the tool relative to its current position.

- Absolute programming uses G90 code, while incremental programming uses G91 code.

- Absolute programming is easier to use when the workpiece is located in a fixed position, while incremental programming is more convenient when the workpiece is moving.

2. What is the purpose of a coolant in CNC machining?

Coolant is used in CNC machining to:

Lubricate the cutting tool

- Reduces friction between the tool and the workpiece.

- Extends tool life.

Cool the workpiece

- Prevents the workpiece from overheating.

- Reduces thermal expansion.

Flush away chips

- Keeps the cutting area clean.

- Improves surface finish.

3. What are the different types of CNC control systems?

The three main types of CNC control systems are:

- Open-loop control: The position of the tool is not measured by the control system, so it relies on the accuracy of the machine’s mechanical components.

- Closed-loop control: The position of the tool is measured by the control system, which uses feedback to correct any errors.

- Adaptive control: The control system monitors the cutting process and makes adjustments to the machining parameters to optimize performance.

4. What are the advantages of using CNC machining over manual machining?

Advantages of CNC machining over manual machining include:

- Increased accuracy and precision.

- Faster production times.

- Reduced scrap rates.

- Improved surface finishes.

- Increased safety.

5. What are some of the challenges of CNC machining?

Some of the challenges of CNC machining include:

- High cost of equipment and tooling.

- Complex programming and setup.

- Need for skilled operators.

- Maintenance and repair costs.

6. What is the difference between G-code and M-code in CNC programming?

G-codes are used to control the movement of the machine, while M-codes are used to control auxiliary functions such as spindle speed, coolant flow, and tool changes.

- G-codes are typically modal, meaning that they remain in effect until they are changed by another G-code.

- M-codes are typically non-modal, meaning that they are only executed once and then they are reset.

7. What is the purpose of a tool offset in CNC machining?

A tool offset is a value that is added to or subtracted from the programmed tool position to compensate for the difference between the actual and commanded tool position.

- Tool offsets are typically used to compensate for tool wear or to adjust the tool position relative to the workpiece.

- Tool offsets can be entered manually or they can be calculated automatically by the CNC control system.

8. What is the difference between a drill and a tap?

A drill is used to create a hole in a workpiece, while a tap is used to create threads in a hole.

- Drills have a pointed tip that is designed to cut through the workpiece.

- Taps have a tapered tip that is designed to create threads in a hole.

9. What is the purpose of a collet in CNC machining?

A collet is a device that is used to hold a cutting tool in a CNC machine.

- Collets are typically made of hardened steel or aluminum.

- Collets are available in a variety of sizes and shapes to accommodate different cutting tools.

10. What is the difference between a boring bar and a milling cutter?

A boring bar is a cutting tool that is used to create holes in a workpiece, while a milling cutter is a cutting tool that is used to create a variety of shapes in a workpiece.

- Boring bars have a single cutting edge that is used to create holes.

- Milling cutters have multiple cutting edges that are used to create a variety of shapes.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for CNC Machine Operator (Computerized Numerical Control Machine Operator).

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the CNC Machine Operator (Computerized Numerical Control Machine Operator)‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

CNC Machine Operators are responsible for the operation and maintenance of Computerized Numerical Control (CNC) machines, which are used to manufacture parts with high precision and accuracy. Their day-to-day responsibilities include:1. Machine Operation

– Set up and operate CNC machines according to blueprints and specifications. – Monitor machine performance and make adjustments to ensure adherence to specifications. – Identify and resolve any issues that arise during the operation of the machine.2. Program Development and Editing

– Develop and edit CNC programs using computer-aided manufacturing (CAM) software. – Optimize program parameters to achieve efficient and accurate machining processes. – Work closely with engineers and designers to review and modify programs.3. Part Inspection and Quality Control

– Inspect finished parts to ensure they meet specifications. – Use precision measuring tools and gauges to verify dimensions, tolerances, and finishes. – Identify and document any defects or non-conformities.4. Machine Maintenance and Troubleshooting

– Perform preventive maintenance on CNC machines, including cleaning, lubrication, and calibration. – Troubleshoot and resolve mechanical, electrical, or software issues with the machine. – Order and install replacement parts as necessary.5. Safety and Compliance

– Adhere to all safety protocols and regulations related to the operation of CNC machines. – Wear appropriate safety gear and use proper handling techniques. – Maintain a clean and organized work area.Interview Tips

To help you ace your interview for a CNC Machine Operator position, consider the following prepration tips:1. Familiarize Yourself with CNC Technology

– Research different types of CNC machines and their applications. – Understand the basics of CAM software and how it is used to generate CNC programs. – Practice reading blueprints and interpreting technical specifications.2. Highlight Your Technical Skills

– Showcase your proficiency in operating and programming CNC machines. – Quantify your experience by providing specific examples of projects you have worked on. – Emphasize your attention to detail and ability to troubleshoot problems effectively.3. Demonstrate Your Safety Knowledge

– Explain your understanding of CNC machine safety protocols. – Describe how you would handle potential hazards and maintain a safe work environment. – Share examples of your commitment to following safety regulations.4. Prepare Questions for the Interviewer

– Ask thoughtful questions that demonstrate your interest in the position and the company. – For example, inquire about the company’s industry, production processes, or growth opportunities. – This shows that you are engaged and eager to learn more about the company.5. Practice Your Communication Skills

– Practice clearly and concisely explaining technical concepts. – Be prepared to discuss your experience and qualifications with confidence. – Demonstrate your ability to work as part of a team and collaborate with others. Remember, preparation is key to success. By following these tips and thoroughly researching the role, you can increase your chances of impressing the interviewer and securing the CNC Machine Operator position.Next Step:

Now that you’re armed with the knowledge of CNC Machine Operator (Computerized Numerical Control Machine Operator) interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for CNC Machine Operator (Computerized Numerical Control Machine Operator) positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini