Feeling lost in a sea of interview questions? Landed that dream interview for CNC Machinist (Computer Numerically Controlled Machinist) but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common CNC Machinist (Computer Numerically Controlled Machinist) interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

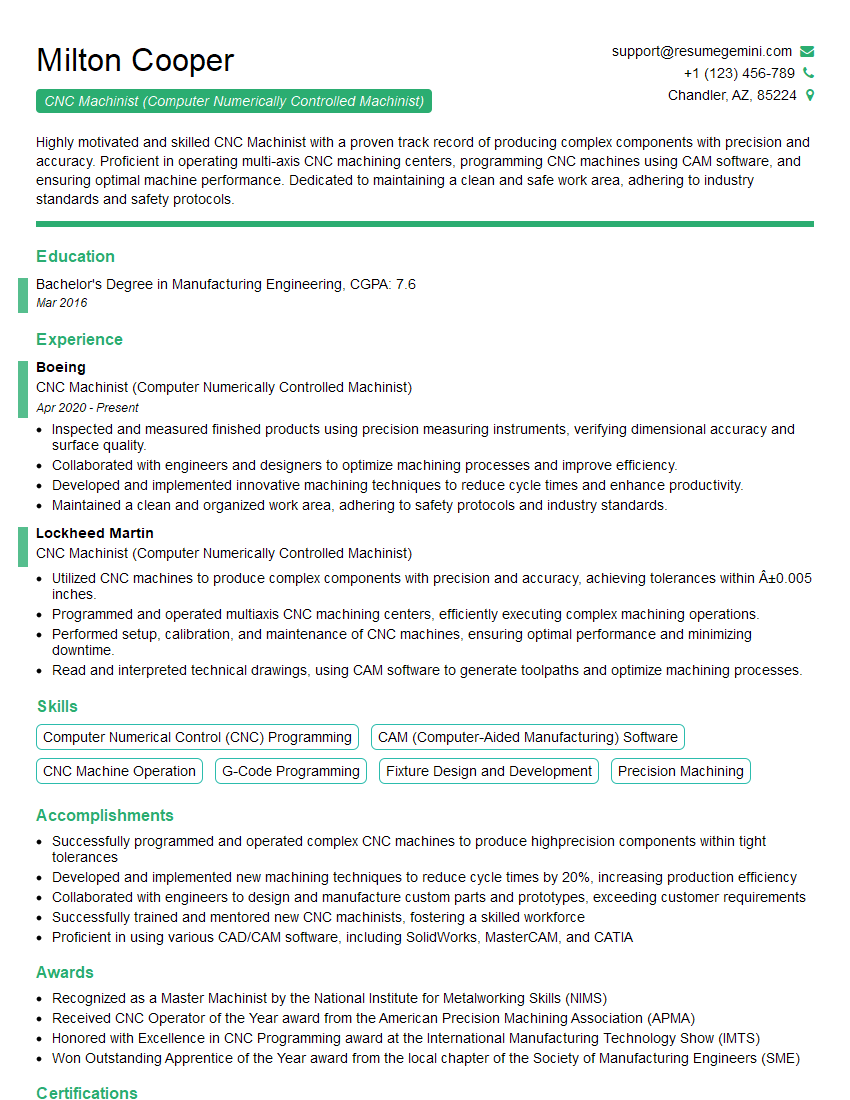

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For CNC Machinist (Computer Numerically Controlled Machinist)

1. Tell me about your experience with CNC machines?

I have been working with CNC machines for the past 5 years. I have experience with a variety of CNC machines, including 3-axis mills, 4-axis mills, and 5-axis mills. I am also proficient in CNC programming and have experience with a variety of CAD/CAM software packages.

2. What are the different types of CNC machines?

Types of CNC Machine

- 3-axis mills

- 4-axis mills

- 5-axis mills

Purpose of CNC Machine

- Cutting

- Drilling

- Milling

- Turning

3. What are the different types of CNC controls?

There are two main types of CNC controls: open-loop controls and closed-loop controls. Open-loop controls do not have any feedback mechanism to correct for errors, while closed-loop controls do. Closed-loop controls are more accurate and reliable than open-loop controls.

4. What are the different types of CNC programming languages?

There are many different CNC programming languages, but the most common are G-code and M-code. G-code is used to control the movement of the CNC machine, while M-code is used to control the other functions of the machine, such as the spindle speed and coolant flow.

5. What are the safety precautions that must be taken when working with CNC machines?

There are many safety precautions that must be taken when working with CNC machines, including:

- Wearing appropriate safety gear, such as safety glasses, gloves, and hearing protection

- Keeping the work area clean and free of debris

- Never operating a CNC machine while under the influence of alcohol or drugs

- Following all of the manufacturer’s safety instructions

6. What are the benefits of using CNC machines?

There are many benefits to using CNC machines, including:

- Increased accuracy and precision

- Reduced labor costs

- Increased productivity

- Improved product quality

7. What are the challenges of working with CNC machines?

There are some challenges to working with CNC machines, including:

- The machines can be complex and difficult to operate

- The machines can be expensive to purchase and maintain

- The machines can be dangerous if not operated properly

8. What is your favorite thing about working with CNC machines?

My favorite thing about working with CNC machines is the challenge. I enjoy learning new things and solving problems. I also enjoy the satisfaction of seeing a finished product that I have created.

9. What is your least favorite thing about working with CNC machines?

My least favorite thing about working with CNC machines is the repetitive nature of some of the work. However, I find that I can overcome this by listening to music or podcasts while I work.

10. What are your career goals?

My career goals are to continue to learn and grow as a CNC machinist. I would like to eventually become a CNC programmer and then a CNC supervisor. I am also interested in learning about other aspects of the manufacturing process, such as design and engineering.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for CNC Machinist (Computer Numerically Controlled Machinist).

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the CNC Machinist (Computer Numerically Controlled Machinist)‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

CNC Machinists are highly skilled professionals who operate computer-controlled machines to create complex and precise parts for various industries. Their key job responsibilities include:

1. Programming and Setup

Interpret and translate engineering drawings and specifications into CNC programs, ensuring accuracy and efficiency in machine operation.

- Select and prepare appropriate cutting tools and materials for each job.

- Calibrate and set up CNC machines, ensuring proper alignment and precision.

2. Machine Operation

Operate CNC machines safely and efficiently, following established procedures.

- Load and secure workpieces into machines.

- Monitor machine operation, making adjustments as needed to optimize performance.

3. Quality Control

Inspect finished parts and compare them to specifications.

- Identify and correct any discrepancies or defects.

- Maintain accurate records of production output and quality.

4. Troubleshooting and Maintenance

Troubleshoot machine malfunctions and identify root causes.

- Perform basic maintenance and repairs to keep CNC machines in optimal condition.

- Collaborate with other departments, such as maintenance and engineering, to resolve complex issues.

Interview Tips

1. Research the Company and Position

Familiarize yourself with the company’s products, services, and industry.

- Review the job description thoroughly and identify the skills and qualifications required.

- Highlight how your experience and expertise align with the company’s needs.

2. Prepare for Technical Questions

Expect questions on CNC programming, machine operation, and quality control techniques.

- Brush up on your knowledge of different CNC codes and programming languages.

- Practice demonstrating your understanding of machine setups, tooling, and inspection procedures.

3. Emphasize Safety and Attention to Detail

CNC Machining requires a strong focus on safety and attention to detail.

- Discuss your commitment to following established safety protocols.

- Provide examples of your ability to produce precise and accurate parts consistently.

4. Showcase Problem-Solving Abilities

Companies value CNC Machinists who can troubleshoot problems effectively.

- Share examples of how you have diagnosed and resolved machine malfunctions in the past.

- Explain your approach to problem-solving and your ability to collaborate with others.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the CNC Machinist (Computer Numerically Controlled Machinist) interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.