Are you gearing up for a career in CNC Mill Operator (Computerized Numerical Control Mill Operator)? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for CNC Mill Operator (Computerized Numerical Control Mill Operator) and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

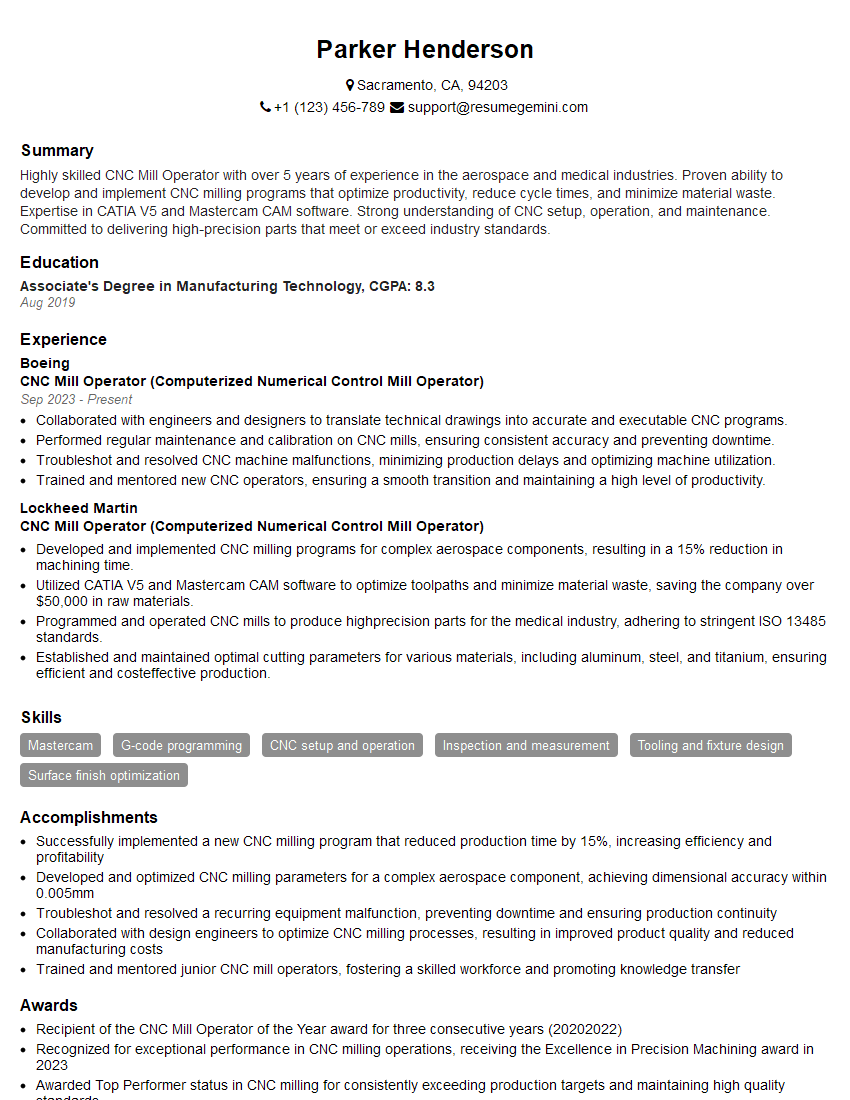

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For CNC Mill Operator (Computerized Numerical Control Mill Operator)

1. Explain the process of setting up a CNC mill for a new job?

The process of setting up a CNC mill for a new job typically involves the following steps:

- Load the CNC program into the machine’s controller.

- Install the appropriate cutting tools into the machine’s toolholder.

- Set the machine’s work offsets and zero point.

- Load the workpiece into the machine’s chuck or fixture.

- Run the CNC program to machine the workpiece.

- Inspect the finished workpiece to ensure that it meets the required specifications.

2. What are the different types of CNC milling operations?

Milling Operations

- Face milling

- Peripheral milling

- Slot milling

- Pocketing

- Profiling

Drilling Operations

- Drilling

- Boring

- Tapping

3. What are the different types of CNC milling machines?

- Vertical machining centers (VMCs)

- Horizontal machining centers (HMCs)

- Bed mills

- Turret mills

- Gantry mills

4. What are the safety precautions that must be taken when operating a CNC mill?

- Always wear appropriate safety gear, including safety glasses, earplugs, and gloves.

- Never operate a CNC mill that is not properly guarded.

- Never reach into the machine’s work area while it is running.

- Be aware of the machine’s moving parts and keep your hands clear of them.

- Never operate a CNC mill that is not in good working order.

5. What are the different types of cutting tools that can be used on a CNC mill?

- End mills

- Face mills

- Drills

- Boring bars

- Taps

6. What are the different types of CNC milling software?

- Computer-aided manufacturing (CAM) software

- Computer-aided design (CAD) software

- Machine control software

7. What are the different types of CNC milling applications?

- Aerospace

- Automotive

- Medical

- Electronics

- Mold making

8. What are the advantages of using a CNC mill?

- Increased accuracy and precision

- Reduced lead times

- Improved surface finishes

- Increased productivity

- Reduced labor costs

9. What are the disadvantages of using a CNC mill?

- High capital investment

- Requires skilled operators

- Can be complex to program

- Can be noisy and generate dust

10. What are the trends in CNC milling?

- Increased use of automation

- Development of new cutting tools and materials

- Integration of new technologies, such as additive manufacturing

- Increased use of CNC milling for rapid prototyping

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for CNC Mill Operator (Computerized Numerical Control Mill Operator).

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the CNC Mill Operator (Computerized Numerical Control Mill Operator)‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

1. Set Up and Operate CNC Machines

CNC Mill Operators are responsible for setting up and operating CNC milling machines to produce parts according to specifications. They must be able to read and interpret blueprints, set up the machine, and program the CNC code. They must also be able to troubleshoot any problems that may arise during the machining process.

2. Inspect and Measure Parts

CNC Mill Operators are responsible for inspecting and measuring parts to ensure that they meet the required specifications. They must be able to use a variety of measuring tools, such as micrometers, calipers, and gauges. They must also be able to identify any defects or errors in the parts.

3. Maintain Equipment

CNC Mill Operators are responsible for maintaining the CNC machines that they operate. They must be able to perform basic maintenance tasks, such as cleaning and lubricating the machines. They must also be able to troubleshoot any problems that may arise with the machines.

4. Work as Part of a Team

CNC Mill Operators often work as part of a team. They must be able to communicate effectively with other team members and to work together to achieve the team’s goals.

Interview Tips

Preparing for an interview for a CNC Mill Operator position can be daunting, but with the right preparation, you can increase your chances of success. Here are a few tips to help you ace the interview:

- Do your research. Before you go to the interview, take some time to research the company and the position. This will help you to understand the company’s culture and the specific requirements of the job.

- Practice answering common interview questions. There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” Practice answering these questions in advance so that you can deliver your answers confidently and concisely.

- Be prepared to talk about your experience. The interviewer will likely ask you about your experience as a CNC Mill Operator. Be prepared to discuss your skills and experience in detail. Highlight your strengths and accomplishments, and be sure to provide specific examples.

- Be enthusiastic and positive. The interviewer will be looking for someone who is enthusiastic about the position and who is positive about their abilities. Be sure to convey your enthusiasm and positivity throughout the interview.

- Dress professionally. First impressions matter, so be sure to dress professionally for your interview. This means wearing a suit or business casual attire.

- Arrive on time. Punctuality is important, so be sure to arrive on time for your interview. This shows the interviewer that you are respectful of their time.

- Be yourself. The most important thing is to be yourself during the interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not.

Next Step:

Now that you’re armed with the knowledge of CNC Mill Operator (Computerized Numerical Control Mill Operator) interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for CNC Mill Operator (Computerized Numerical Control Mill Operator) positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini