Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the CNC Programmer (Computer Numerical Control Programmer) interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a CNC Programmer (Computer Numerical Control Programmer) so you can tailor your answers to impress potential employers.

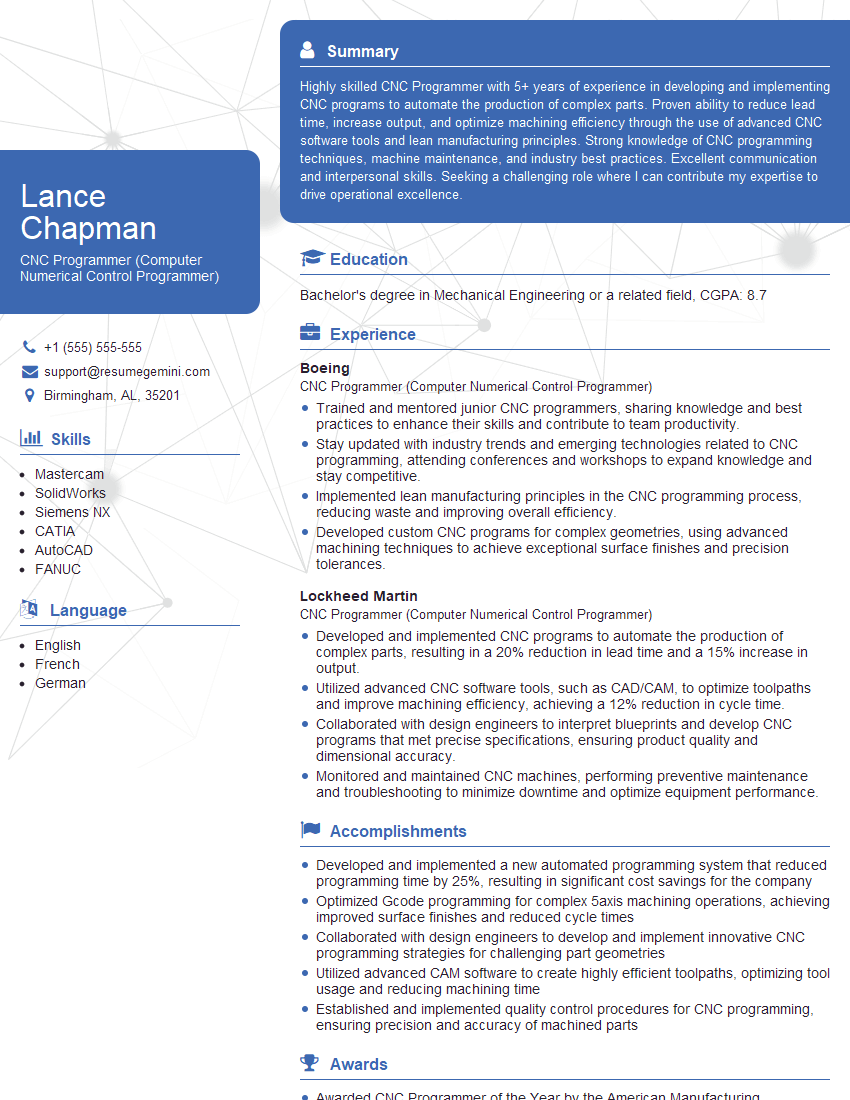

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For CNC Programmer (Computer Numerical Control Programmer)

1. Describe the process of creating a CNC program from scratch, including the use of CAM software.

The process of creating a CNC program from scratch involves several steps:

- Design the part using CAD software. This involves creating a 3D model of the part, including all of its features and dimensions.

- Generate the toolpath using CAM software. This involves creating a set of instructions that tell the CNC machine how to move its tools to create the part.

- Post-process the program to generate the G-code that the CNC machine can understand.

- Transfer the program to the CNC machine and run it.

2. What are the key factors to consider when selecting a CNC cutting tool?

The key factors to consider when selecting a CNC cutting tool include:

- The material of the workpiece. Different materials require different types of cutting tools.

- The size and shape of the workpiece. The cutting tool must be able to reach all of the areas of the workpiece that need to be cut.

- The speed and feed rate of the CNC machine. The cutting tool must be able to withstand the speeds and feeds that will be used.

- The cost of the cutting tool. The cutting tool should be cost-effective for the application.

3. How do you ensure the accuracy and precision of CNC programs?

There are several ways to ensure the accuracy and precision of CNC programs:

- Use high-quality CAM software. CAM software that is designed specifically for the type of CNC machine that you are using will help to ensure that the program is accurate and precise.

- Proofread the program carefully before running it. Look for any errors in the code, and make sure that the program is complete.

- Run the program on a test workpiece before running it on the actual workpiece. This will help to identify any problems with the program.

- Use proper fixturing to hold the workpiece in place. This will help to prevent the workpiece from moving during the machining process.

4. What are the different types of CNC machines, and what are their advantages and disadvantages?

There are many different types of CNC machines, each with its own advantages and disadvantages. Some of the most common types of CNC machines include:

- Vertical milling machines are used to create parts by cutting away material from a block of metal.

- Horizontal milling machines are similar to vertical milling machines, but they are used to create parts by cutting away material from a bar of metal.

- Turning machines are used to create parts by rotating a workpiece while cutting away material with a cutting tool.

- Grinding machines are used to create parts by abrading material away from a workpiece with a grinding wheel.

5. What are the different types of CNC controls, and what are their advantages and disadvantages?

There are two main types of CNC controls: open-loop controls and closed-loop controls.

- Open-loop controls do not have any feedback mechanism to check the accuracy of the machine’s movements. This means that the machine is not able to correct any errors that occur during the machining process.

- Closed-loop controls have a feedback mechanism to check the accuracy of the machine’s movements. This means that the machine is able to correct any errors that occur during the machining process.

6. What are the different types of CNC programming languages, and what are their advantages and disadvantages?

There are many different types of CNC programming languages, each with its own advantages and disadvantages. Some of the most common types of CNC programming languages include:

- G-code is a general-purpose CNC programming language that is used to control a wide variety of CNC machines.

- APT is a high-level CNC programming language that is used to create complex parts.

- DNC is a CNC programming language that is used to transfer programs from a computer to a CNC machine.

7. What are the different types of CNC software, and what are their advantages and disadvantages?

There are many different types of CNC software, each with its own advantages and disadvantages. Some of the most common types of CNC software include:

- CAM software is used to create CNC programs from CAD models.

- Simulation software is used to simulate the machining process before running it on the actual CNC machine.

- Monitoring software is used to monitor the CNC machine during the machining process.

8. What are the different types of CNC applications, and what are their advantages and disadvantages?

There are many different types of CNC applications, each with its own advantages and disadvantages. Some of the most common types of CNC applications include:

- Machining is the process of using a CNC machine to create parts from metal, plastic, or other materials.

- Rapid prototyping is the process of using a CNC machine to create prototypes of parts quickly and easily.

- Inspection is the process of using a CNC machine to inspect parts for quality and accuracy.

9. What are the career opportunities for CNC programmers?

There are many career opportunities for CNC programmers. CNC programmers can work in a variety of industries, including manufacturing, aerospace, and automotive. CNC programmers can also work as self-employed contractors.

10. What are the skills and qualifications that are required for a CNC programmer?

CNC programmers typically need to have the following skills and qualifications:

- A strong understanding of CNC programming

- Experience with CAM software

- Experience with CNC machines

- A strong understanding of mathematics

- A strong understanding of physics

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for CNC Programmer (Computer Numerical Control Programmer).

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the CNC Programmer (Computer Numerical Control Programmer)‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

CNC Programmers are responsible for programming computer numerical control (CNC) machines. CNC machines are used to automate the manufacturing process, and CNC Programmers create the programs that tell the CNC machines what to do.

1. Creating CNC programs

CNC Programmers use computer-aided design (CAD) software to create CNC programs. These programs contain detailed instructions on how the CNC machine should cut, shape, and form the workpiece.

2. Setting up and running CNC machines

Once a CNC program has been created, the CNC Programmer sets up and runs the CNC machine. This involves loading the workpiece into the machine, setting the machine parameters, and starting the program. The CNC Programmer monitors the machine during operation and makes adjustments as necessary.

3. Troubleshooting CNC machine problems

CNC machines can sometimes experience problems during operation. CNC Programmers are responsible for troubleshooting and fixing these problems. This may involve making adjustments to the CNC program, the CNC machine, or the workpiece.

4. Maintain CNC machines

CNC Programmers are responsible for maintaining CNC machines. This involves performing regular maintenance tasks, such as cleaning and lubricating the machine. CNC Programmers also perform preventative maintenance tasks, such as inspecting the machine for signs of wear and tear.

Interview Tips

There are a number of things you can do to prepare for an interview for a CNC Programmer position.

1. Research the company and the position

Before you go on an interview, it’s important to do your research. This means learning about the company and the specific position you’re applying for. You should also learn about the industry and the current trends in CNC programming.

2. Practice your answers to common interview questions

There are a number of common interview questions that you may be asked during an interview for a CNC Programmer position. Some of these questions include:

- Why are you interested in this position?

- What are your strengths and weaknesses as a CNC Programmer?

- What is your experience with CNC programming?

- What are your career goals?

- How do you stay up-to-date on the latest trends in CNC programming?

3. Bring a portfolio of your work

If you have any experience with CNC programming, it’s a good idea to bring a portfolio of your work to your interview. This will give the interviewer a chance to see your skills and experience firsthand.

4. Be prepared to talk about your safety experience

CNC machines can be dangerous, so it’s important to be prepared to talk about your safety experience during your interview. This includes discussing your knowledge of safety procedures and your experience working with CNC machines.

5. Dress professionally

It’s important to dress professionally for your interview. This means wearing business attire and being well-groomed. First impressions matter, so make sure you put your best foot forward.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a CNC Programmer (Computer Numerical Control Programmer), it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for CNC Programmer (Computer Numerical Control Programmer) positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.