Feeling lost in a sea of interview questions? Landed that dream interview for CNC Programmer (Computerized Numerical Control Programmer) but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common CNC Programmer (Computerized Numerical Control Programmer) interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

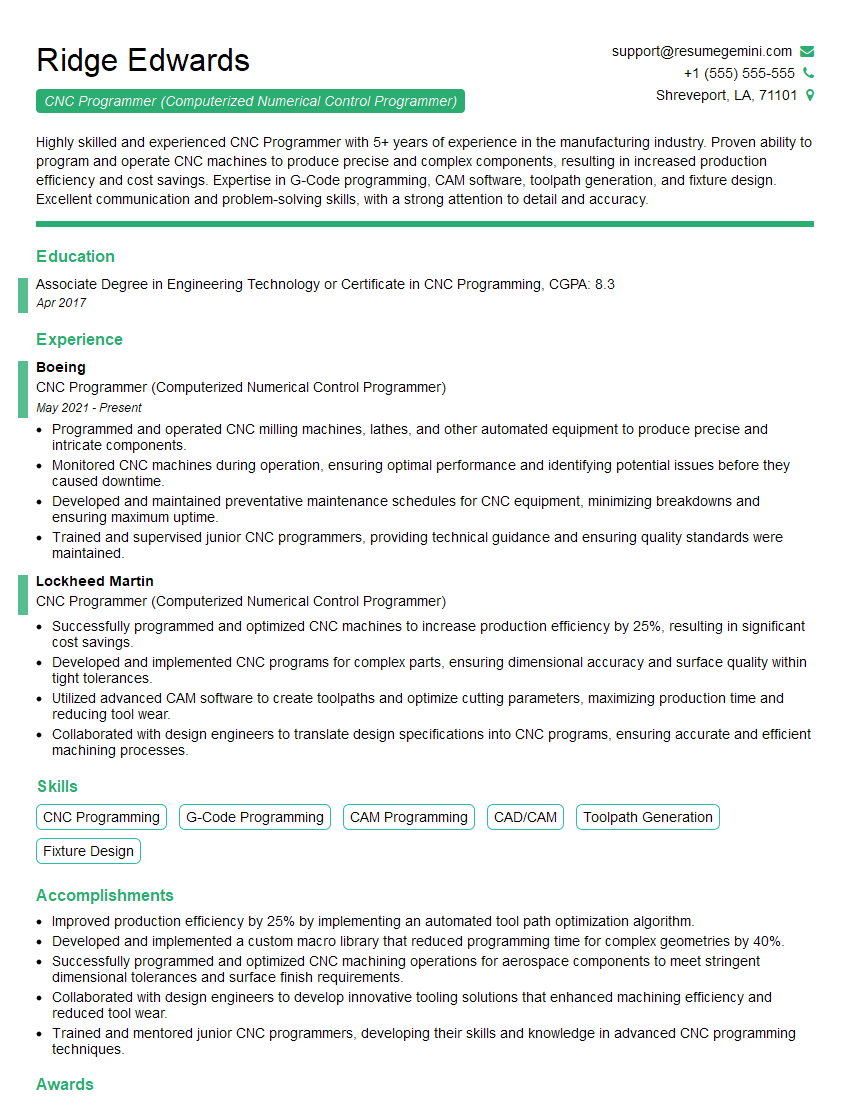

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For CNC Programmer (Computerized Numerical Control Programmer)

1. What is the role of a CNC Programmer?

In the role of a CNC Programmer, I am responsible for creating and modifying computer-aided design (CAD) models to generate code that drives CNC machines.

2. What are the key skills required for a CNC Programmer?

Technical Skills

- Proficient in CAD software such as AutoCAD, SolidWorks, or Mastercam

- Strong knowledge of CNC programming languages (e.g., G-code, APT)

- Understanding of CNC machine operation and setup

- Experience with CAM systems (e.g., Mastercam, ESPRIT, BobCAD-CAM)

Soft Skills

- Problem-solving and analytical abilities

- Attention to detail and accuracy

- Excellent communication and teamwork skills

3. Describe your experience in using CAD/CAM software.

I have extensive experience using CAD software such as AutoCAD and SolidWorks to create 3D models and technical drawings. I also have proficiency in CAM systems, including Mastercam and ESPRIT, which I use to generate CNC code and optimize machining processes.

4. Explain the different types of CNC machines and their applications.

There are various types of CNC machines, each designed for specific tasks. Common types include:

- Milling machines: Used for creating complex shapes and features

- Turning machines: Employed for cylindrical parts and precision machining

- Grinding machines: Utilized for high-precision finishing and shaping

- Laser cutting machines: Ideal for intricate cuts and engravings on various materials

- Waterjet cutting machines: Capable of cutting a wide range of materials with high accuracy

5. Discuss the importance of tool selection and feed rates in CNC programming.

Tool selection and feed rates play a crucial role in CNC programming. The appropriate tool geometry and material influence the surface finish, machining efficiency, and tool life. Feed rates determine the speed at which the tool moves, affecting factors such as cutting forces, chip formation, and workpiece quality.

6. Describe your approach to optimizing CNC programs for efficiency and accuracy.

To optimize CNC programs, I follow a systematic approach:

- Analyze the part geometry and identify critical features

- Plan toolpaths that minimize tool changes and reduce machining time

- Select appropriate cutting parameters based on tool material, workpiece material, and desired surface finish

- Utilize simulation tools to verify program functionality and detect potential errors

- Conduct trial runs to fine-tune program parameters and optimize performance

7. Explain the role of coordinate systems in CNC programming.

Coordinate systems are essential in CNC programming as they define the spatial relationship between different elements. The primary coordinate system, known as the Machine Coordinate System (MCS), is fixed to the machine itself. Other coordinate systems, such as the Workpiece Coordinate System (WCS) and the Tool Coordinate System (TCS), are defined relative to the MCS and allow for easier programming of complex geometries.

8. Describe your experience in troubleshooting and resolving CNC machining problems.

During my experience as a CNC Programmer, I have encountered various machining problems and developed effective troubleshooting strategies. I utilize a combination of analytical thinking, observation, and diagnostic tools to identify the root cause of issues. My approach involves:

- Examining the CNC program for errors or inconsistencies

- Inspecting the CNC machine and tooling for potential malfunctions

- Analyzing the workpiece and comparing it to the design specifications

- Consulting with experienced machinists or engineers for additional insights

9. Explain the importance of safety protocols in CNC programming and operation.

Safety is paramount in CNC programming and operation. I strictly adhere to safety protocols to prevent accidents and ensure a safe work environment. These protocols include:

- Wearing appropriate personal protective equipment (PPE), such as safety glasses, gloves, and earplugs

- Following proper machine operation procedures and avoiding contact with moving parts

- Inspecting the CNC machine and tooling regularly for potential hazards

- Staying alert and aware of the surroundings

- Receiving regular training on safety best practices

10. Describe your ideal work environment and how you contribute to a team.

I thrive in a collaborative and challenging work environment where I can contribute my skills and learn from others. As a team player, I value open communication, shared knowledge, and a strong work ethic. I am always eager to support my colleagues, share my expertise, and work towards the team’s success.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for CNC Programmer (Computerized Numerical Control Programmer).

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the CNC Programmer (Computerized Numerical Control Programmer)‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

CNC Programmers are responsible for developing and implementing Computerized Numerical Control (CNC) programs and codes for the precision machining of parts on CNC Machines.

1. Develop and Implement CNC Programming

CNC Programmers are responsible for creating CNC programs and codes to machine parts and components according to the given design specifications and drawings.

- Analyze design specifications and drawings to understand the required machining operations.

- Select the appropriate CNC machine and tools for the specific part to be manufactured.

2. Design and Optimize CNC Code

Programmers optimize CNC code for efficiency, minimizing production time and material waste.

- Design and optimize CNC code to ensure accuracy, speed, and efficiency of CNC machine operations.

- Identify and resolve errors and issues in CNC code to ensure smooth operation.

3. Machine Setup and Operation

Ensure that CNC machines are properly set up and operated.

- Set up and operate CNC machines according to the developed CNC programs.

- Monitor CNC machine operations to ensure that they meet quality standards.

4. Quality Control and Inspection

Verify that the machined parts meet the required specifications

- Inspect and verify the dimensions and quality of the machined parts.

- Identify and correct any deviations or defects in the machined parts.

Interview Tips

Preparing for a CNC Programmer interview requires a combination of technical knowledge, soft skills, and preparation strategies. Here are a few tips to help you ace the interview:

1. Technical Knowledge

Ensure you have a strong understanding of CNC programming principles, machine operations, and industry-specific software.

- Review CNC programming languages such as G-code and M-code.

- Familiarize yourself with different types of CNC machines, their capabilities, and applications.

2. Practical Experience

Highlight your hands-on experience in CNC programming and machine setup.

- Quantify your experience by providing specific examples of CNC programs you have developed and implemented.

- Demonstrate your understanding of machine setup and operation, including tool selection and workholding.

3. Soft Skills

Emphasize your attention to detail, problem-solving abilities, and communication skills.

- Highlight your ability to analyze complex design specifications and translate them into efficient CNC code.

- Demonstrate your problem-solving skills by describing instances where you identified and resolved errors in CNC code or machine setups.

4. Interview Preparation

Research the company and the specific role you are applying for.

- Review the job description carefully and tailor your answers to the specific requirements.

- Prepare examples of your CNC programming work and be ready to discuss them during the interview.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the CNC Programmer (Computerized Numerical Control Programmer) role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.