Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted CNC Technician (Computer Numerical Control Technician) position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

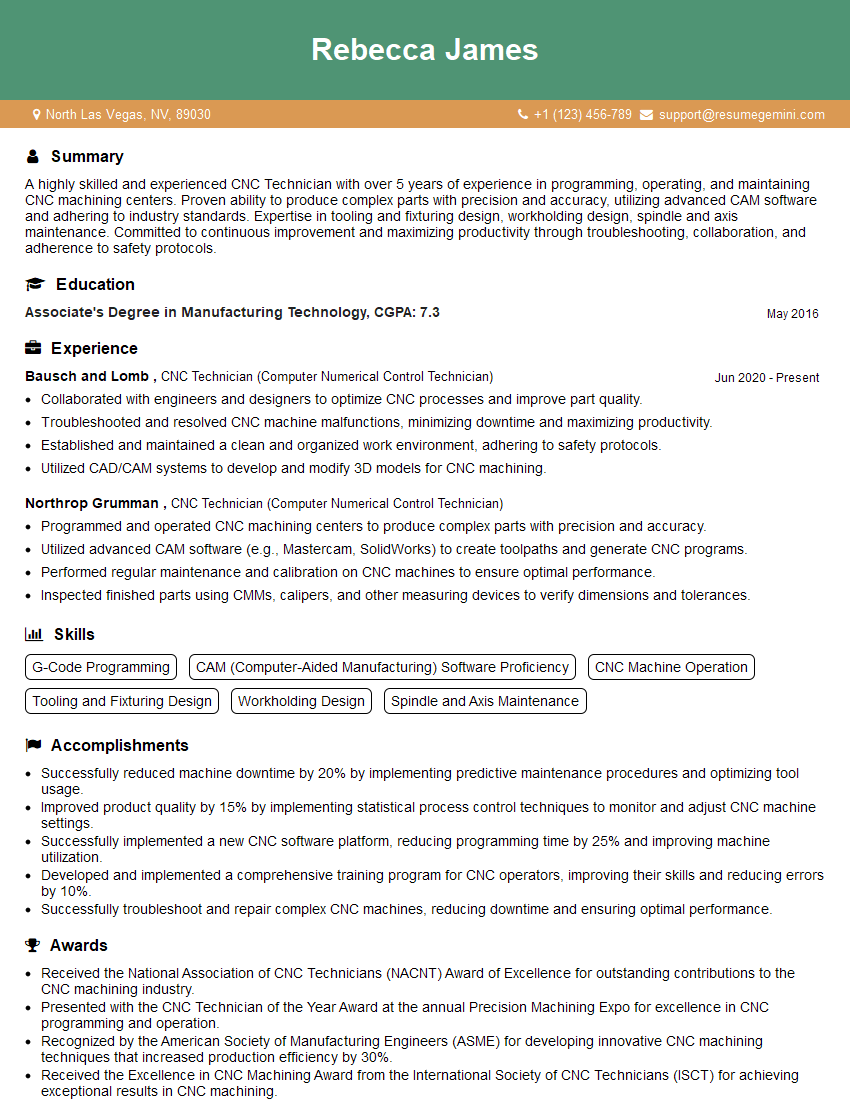

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For CNC Technician (Computer Numerical Control Technician)

1. What are the different types of CNC machines, and what are their respective applications?

There are several types of CNC machines, each designed for specific applications. Some common types include:

- CNC Mills: Used for cutting and shaping metal, plastic, and other materials using rotating cutting tools.

- CNC Lathes: Used for turning and shaping cylindrical workpieces, such as shafts and gears.

- CNC Routers: Similar to CNC mills but use smaller cutting tools and are designed for cutting and shaping materials like wood, plastic, and composites.

- CNC Wire EDM (Electrical Discharge Machining) Machines: Used for precision cutting of complex shapes using an electrical discharge process.

- CNC Plasma Cutters: Used for cutting металл sheets using a plasma torch.

2. Explain the process of creating a CNC program.

: Code Generation

- The CNC program is typically created using a computer-aided design (CAD) or computer-aided manufacturing (CAM) software.

- The CAD/CAM software generates the G-code, which is a specific programming language used to control CNC machines.

Subheading: Machine Setup

- The G-code program is then loaded into the CNC machine’s controller.

- The machine operator sets up the machine according to the program’s specifications, including the type of material, cutting tools, and feed rates.

Subheading: Program Execution

- Once the machine is set up, the CNC program is executed.

- The CNC controller sends signals to the machine’s motors, drives, and other components to execute the program’s commands.

3. What is the difference between absolute and incremental programming?

In absolute programming, all positions and movements are specified relative to the machine’s home position. This means that every movement is calculated from the starting point.

In incremental programming, positions and movements are specified relative to the current position of the machine. This means that each movement is calculated from the previous position.

4. What are the different types of cutting tools used in CNC machining, and how do you select the appropriate tool for a specific job?

The type of cutting tool used in CNC machining depends on the material being machined, the desired finish, and the specific operation being performed. Common types of cutting tools include:

- End mills: Used for a variety of operations, including milling, drilling, and pocketing.

- Drills: Used for creating holes in metal and other materials.

- Taps: Used for cutting threads in holes.

- Reamer: Used for enlarging and finishing holes.

- Carbide inserts: Used for high-speed and heavy-duty cutting operations.

When selecting a cutting tool, consider the following factors:

- Type of material being machined

- Desired surface finish

- Specific operation being performed

- Machine tool capabilities

5. What are the different types of CNC controls, and what are their respective advantages and disadvantages?

- Manual Control: The operator manually controls the machine’s movements using joysticks, knobs, or buttons.

- Computer Numerical Control (CNC): The machine is controlled by a computer that executes a pre-programmed set of instructions.

- Direct Numerical Control (DNC): Similar to CNC, but the program is stored on a central computer and transmitted to the machine as needed.

- Adaptive Control: The machine can adjust its operating parameters based on feedback from sensors.

6. What are the safety precautions that must be followed when working with CNC machines?

- Wear proper safety gear, including eye protection, gloves, and earplugs.

- Keep the work area clean and free of debris.

- Never operate a CNC machine without proper training.

- Be aware of the machine’s moving parts and avoid getting caught in them.

- Follow all posted safety instructions.

7. What are the common maintenance tasks that need to be performed on CNC machines?

- Lubricate moving parts.

- Clean the machine and remove chips and debris.

- Inspect cutting tools and replace them when necessary.

- Calibrate the machine’s axes and spindle.

- Perform regular software updates.

8. What are some of the challenges you have faced as a CNC Technician, and how did you overcome them?

There are various challenges that CNC Technicians may encounter, and the solutions vary depending on the specific situation.

- Machine breakdowns: Troubleshoot the problem, identify the faulty component, and repair or replace it.

- Program errors: Analyze the program, identify the errors, and correct them.

- Material defects: Inspect the material, identify the defects, and determine if the material can still be used.

- Safety hazards: Identify the potential hazards, implement safety measures, and train operators on safety procedures.

9. What are your career goals and aspirations as a CNC Technician?

As a CNC Technician, my career goals include:

- Developing expertise in CNC machining and programming.

- Working on complex and challenging CNC projects.

- Contributing to the efficiency and productivity of the manufacturing process.

- Assuming leadership responsibilities in the CNC department.

- Staying abreast of the latest CNC technologies and advancements.

10. Have you worked with any specific CNC software or control systems in the past?

- Siemens

- Fanuc

- Heidenhain

- Mastercam

- SolidWorks

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for CNC Technician (Computer Numerical Control Technician).

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the CNC Technician (Computer Numerical Control Technician)‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

CNC Technicians, also known as Computer Numerical Control Technicians, play a crucial role in modern manufacturing by programming, operating, and maintaining Computer Numerical Control (CNC) machines. These machines are responsible for automating a wide range of manufacturing processes, including cutting, drilling, and shaping. Key job responsibilities of a CNC Technician include:

1. CNC Machine Operation and Programming

Operate and program CNC machines to execute specific manufacturing processes based on computer-aided design (CAD) files.

2. Fixture Setup and Tooling

Setup and align workpieces and fixtures on CNC machines. Select and install appropriate cutting tools and ensure the machine is calibrated correctly.

3. Process Monitoring and Quality Control

Monitor CNC machines during operation to ensure they are functioning as intended. Inspect parts produced by CNC machines to ensure they meet specifications and quality standards.

4. Troubleshooting and Maintenance

Troubleshoot and resolve any issues or malfunctions with CNC machines. Perform preventive maintenance tasks to ensure optimal performance and longevity of the machines.

5. Safety Compliance

Adhere to all safety regulations and procedures related to CNC machine operation and maintenance. Ensure the work environment is safe and organized.

Interview Tips

Preparing thoroughly for a CNC Technician interview can significantly increase your chances of success. Here are some valuable tips to help you ace the interview:

1. Research the Company and Position

Before the interview, take the time to research the company and the specific CNC Technician position you are applying for. This will give you a better understanding of the company’s culture, goals, and the job’s expectations.

2. Highlight Your Skills and Experience

Emphasize your relevant skills and experience in CNC machine operation, programming, troubleshooting, and maintenance. Quantify your accomplishments and provide specific examples of your contributions to previous projects.

3. Practice Answering Common Interview Questions

Familiarize yourself with common interview questions for CNC Technicians. Prepare thoughtful answers that demonstrate your knowledge, skills, and enthusiasm for the field.

4. Show Your Passion for CNC Technology

Express your passion for CNC technology and your eagerness to learn and grow within the field. Highlight your knowledge of industry advancements and any personal projects you have undertaken involving CNC.

5. Dress Professionally and Arrive Punctually

Make a positive impression by dressing professionally and arriving for the interview on time. Punctuality and a professional appearance show respect for the interviewer and the company.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the CNC Technician (Computer Numerical Control Technician) role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.