Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Coagulating Bath Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

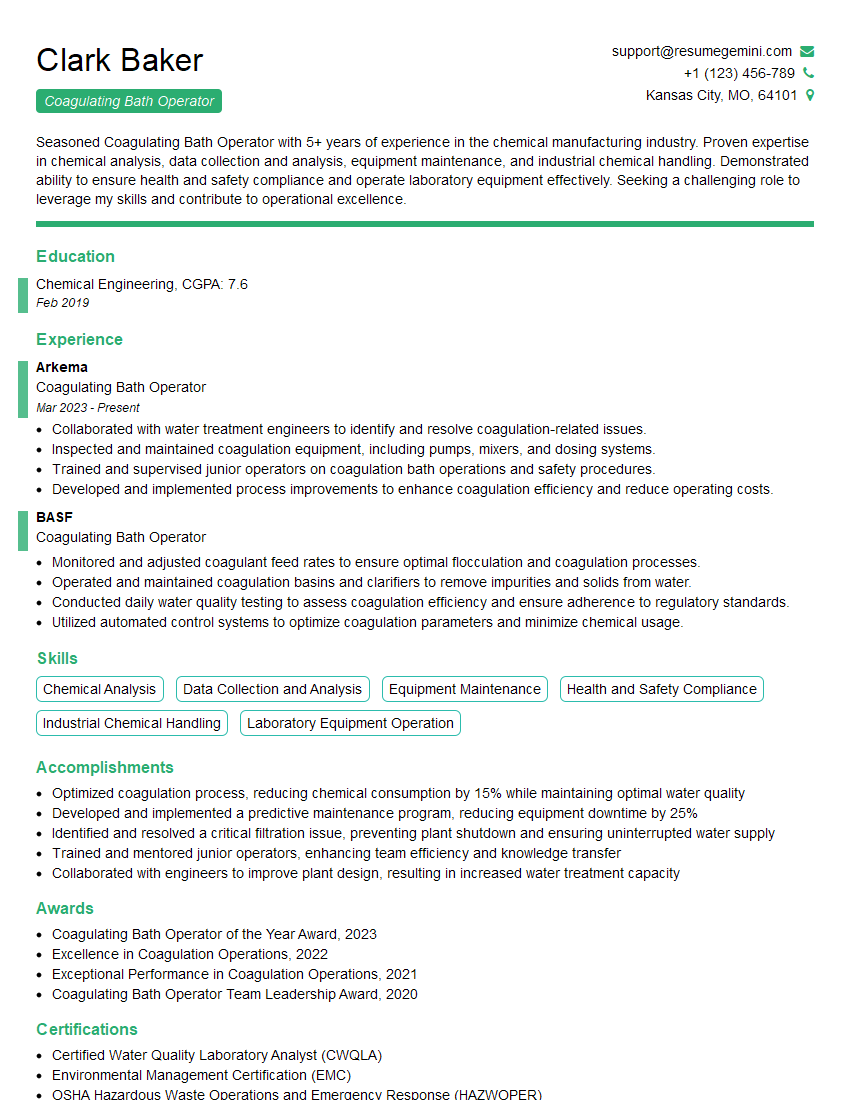

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Coagulating Bath Operator

1. What are the key responsibilities of a Coagulating Bath Operator?

As a Coagulating Bath Operator, my responsibilities include:

- Monitoring and controlling the coagulation bath process to ensure optimal coagulation of latex particles

- Maintaining and calibrating equipment used in the coagulation bath process, including pH meters, conductivity meters, and temperature control systems

- Performing quality control tests on the coagulated latex particles to ensure they meet specifications

- Troubleshooting and resolving any issues that may arise during the coagulation bath process

- Adhering to all safety regulations and procedures

2. What are the different types of coagulation baths used in the rubber industry?

Chemical coagulation

- Involves the addition of a chemical coagulant to the latex dispersion to destabilize the latex particles and promote coagulation

- Commonly used coagulants include calcium chloride, aluminum sulfate, and magnesium sulfate

Electrochemical coagulation

- Uses an electric current to destabilize the latex particles and promote coagulation

- Offers advantages such as reduced chemical usage and improved particle stability

3. What are the critical parameters that need to be controlled in the coagulation bath process?

The critical parameters that need to be controlled in the coagulation bath process include:

- pH level: The pH of the coagulation bath affects the charge on the latex particles and the rate of coagulation

- Temperature: The temperature of the coagulation bath affects the viscosity of the latex and the rate of coagulation

- Coagulant concentration: The concentration of the coagulant in the coagulation bath affects the rate and extent of coagulation

- Mixing intensity: The intensity of mixing in the coagulation bath affects the dispersion of the latex particles and the rate of coagulation

4. What are the common problems that can occur during the coagulation bath process and how do you troubleshoot them?

Common problems that can occur during the coagulation bath process include:

- Incomplete coagulation: This can be caused by insufficient coagulant concentration, low temperature, or high pH

- Over-coagulation: This can be caused by excessive coagulant concentration, high temperature, or low pH

- Flocculation: This can be caused by excessive mixing intensity or the presence of impurities in the latex

- Adjusting the coagulant concentration

- Adjusting the temperature

- Adjusting the pH

- Adjusting the mixing intensity

- Checking for and removing impurities

5. What are the safety precautions that need to be taken when working with coagulation baths?

The safety precautions that need to be taken when working with coagulation baths include:

- Wearing appropriate personal protective equipment, such as gloves, goggles, and a lab coat

- Handling chemicals with care and following proper disposal procedures

- Being aware of the potential for spills and leaks and having appropriate spill response procedures in place

- Ventilating the work area properly to avoid exposure to harmful fumes

6. What is the importance of coagulation in the rubber industry?

Coagulation is an important step in the rubber manufacturing process because it:

- Separates the rubber particles from the water and other impurities

- Improves the stability of the rubber particles

- Facilitates the further processing of the rubber

7. What are the different methods used to coagulate latex?

- Chemical coagulation: This method uses chemicals, such as calcium chloride or magnesium sulfate, to destabilize the latex particles and cause them to coagulate

- Electrochemical coagulation: This method uses an electric current to destabilize the latex particles and cause them to coagulate

- Thermal coagulation: This method uses heat to destabilize the latex particles and cause them to coagulate

8. What are the factors that affect the rate of coagulation?

- The type of coagulant used

- The concentration of the coagulant

- The temperature of the latex

- The pH of the latex

- The presence of other ions in the latex

9. What are the advantages and disadvantages of using chemical coagulation?

Advantages:

- Chemical coagulation is a relatively simple and inexpensive process

- It is effective in coagulating a wide range of latex types

- The rate of coagulation can be controlled by adjusting the concentration of the coagulant

Disadvantages:

- Chemical coagulation can produce harmful byproducts

- The coagulant can remain in the latex and affect the properties of the final product

10. What are the advantages and disadvantages of using electrochemical coagulation?

Advantages:

- Electrochemical coagulation does not produce harmful byproducts

- The coagulant is not present in the final product

- The rate of coagulation can be controlled by adjusting the electric current

Disadvantages:

- Electrochemical coagulation requires specialized equipment

- It is not as effective in coagulating some types of latex as chemical coagulation

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Coagulating Bath Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Coagulating Bath Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Coagulating Bath Operator plays a crucial role in the water treatment process by operating and maintaining coagulating baths to remove impurities and contaminants from water.

1. Coagulant Dosing and Monitoring

The operator ensures the accurate dosing of coagulants into the water, monitoring the pH and other parameters to optimize coagulation.

- Determines optimal coagulant dosage based on water quality parameters

- Monitors pH, turbidity, and other indicators to ensure effective coagulation

2. Coagulating Bath Maintenance

To ensure efficient coagulation, the operator maintains the coagulating bath by adjusting pH, temperature, and mixing conditions.

- Controlls pH and temperature to facilitate optimal coagulation reactions

- Ensures adequate mixing to promote floc formation and settling

3. Flocculation and Sedimentation Monitoring

The operator monitors flocculation and sedimentation processes to ensure proper particle settling and removal.

- Observes floc formation and adjusts process parameters to enhance settling

- Monitors sedimentation tanks to ensure effective solids removal

4. Sludge Handling and Disposal

The operator manages the sludge generated during the coagulation process, ensuring proper disposal and minimizing environmental impact.

- Collects and removes sludge from sedimentation tanks

- Follows established procedures for sludge disposal, adhering to environmental regulations

Interview Preparation Tips

To ace the interview for a Coagulating Bath Operator position, it’s essential to prepare thoroughly and demonstrate your knowledge and skills.

1. Research the Company and Position

Familiarize yourself with the company’s background, industry, and specific role requirements to understand the context of your application.

- Visit the company website and review their mission, vision, and values

- Read the job description carefully to identify key responsibilities and qualifications

2. Highlight Relevant Experience and Skills

Emphasize your experience in water treatment operations, particularly in coagulation processes. Showcase your skills in monitoring, maintaining, and troubleshooting coagulation systems.

- Quantify your accomplishments and provide specific examples of your contributions

- Mention any certifications or training related to water treatment or coagulation

3. Prepare for Technical Questions

Be prepared to answer questions about the coagulation process, coagulants, and water treatment chemistry. Practice explaining the role of pH, temperature, and mixing in coagulation.

- Review textbooks and online resources to refresh your knowledge

- Consider preparing flashcards or notes to assist you during the interview

4. Emphasize Safety and Environmental Awareness

Coagulation bath operators must prioritize safety and environmental compliance. Emphasize your understanding of safety protocols and your commitment to environmental protection.

- Discuss your experience in handling chemicals and following safety procedures

- Explain your knowledge of environmental regulations related to sludge disposal

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Coagulating Bath Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.