Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Coal Cutter position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

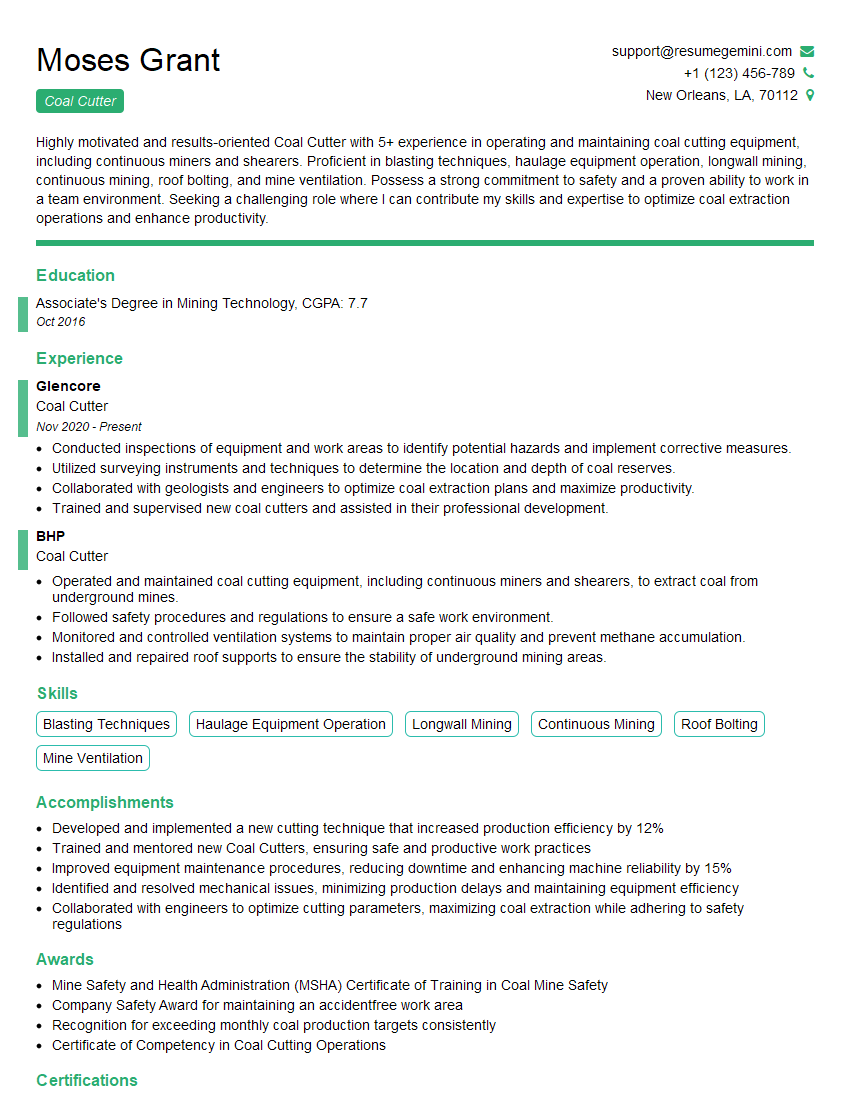

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Coal Cutter

1. Explain the operation and components of a coal cutter machine?

A coal cutter machine is a heavy-duty piece of equipment used in underground coal mines to extract coal from the seam. It consists of a cutting head, conveyor system, and hydraulic system. The cutting head is equipped with rotating cutting bits that break the coal into smaller pieces, while the conveyor system transports the coal away from the cutting face. The hydraulic system powers the cutting head and conveyor system.

2. What are the different types of coal cutter machines?

Continuous miners

- These machines combine cutting, gathering, and conveying functions into a single unit.

- They are highly efficient and can operate in various seam conditions.

Shearer loaders

- These machines use a rotating drum with cutting bits to cut the coal.

- They are often used in conjunction with a conveyor system to transport the coal away from the cutting face.

Longwall shearers

- These machines are used in longwall mining operations and cut the coal in a continuous line from the face.

- They are highly automated and can achieve high production rates.

3. What factors should be considered when selecting a coal cutter machine?

- Seam thickness and hardness

- Mining method

- Production requirements

- Available infrastructure

- Safety and environmental considerations

4. How do you maintain and troubleshoot a coal cutter machine?

Maintaining a coal cutter machine involves regular inspections, lubrication, and repairs. Troubleshooting involves identifying and resolving issues that affect the machine’s operation, such as electrical problems, hydraulic leaks, or cutting head malfunctions.

5. What safety precautions should be taken when operating a coal cutter machine?

- Wear appropriate personal protective equipment (PPE)

- Inspect the machine before operation

- Follow established operating procedures

- Be aware of surroundings and potential hazards

- Report any issues or concerns to supervisors

6. What are the common challenges and solutions in coal cutting operations?

Challenges

- Difficult seam conditions

- Equipment breakdowns

- Safety hazards

- Environmental concerns

Solutions

- Use appropriate cutting techniques and equipment

- Implement effective maintenance and repair strategies

- Follow strict safety protocols

- Adopt environmentally friendly practices

7. How do you stay up-to-date with advancements in coal cutting technology?

- Attend industry conferences and exhibitions

- Read technical journals and publications

- Consult with equipment manufacturers and experts

8. What are your strengths and weaknesses as a coal cutter operator?

Strengths

- Strong understanding of coal cutting principles and practices

- Excellent operating skills and experience

- Commitment to safety and quality

- Ability to work independently and as part of a team

Weaknesses

- Limited experience with specific types of coal cutter machines

- Need to improve troubleshooting and repair skills

9. Why are you interested in this coal cutter operator position?

- Passion for the mining industry

- Desire to contribute to safe and efficient coal production

- Opportunity to learn and grow professionally

- Alignment with my skills and experience

10. What are your career goals and aspirations?

- Advance my skills and become a highly proficient coal cutter operator

- Contribute to the success of the mining operation

- Explore opportunities for professional development and leadership roles

- Make a positive impact on the industry

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Coal Cutter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Coal Cutter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Coal Cutter, also known as a Miner, is a skilled professional responsible for extracting coal from underground mines. Their primary duties encompass the operation and maintenance of coal cutting machines, ensuring efficient and safe coal production.

1. Operate Coal Cutting Machines

Coal Cutters are proficient in operating various types of coal cutting machines, including continuous miners, longwall shearers, and roof bolters. They expertly navigate these machines through complex underground environments, precisely extracting coal while adhering to safety protocols.

2. Ensure Machine Maintenance and Repair

Coal Cutters play a crucial role in maintaining and repairing coal cutting machines. They conduct regular inspections, identify potential issues, and perform necessary repairs to keep equipment in optimal working condition. Their expertise ensures smooth operations and minimizes downtime.

3. Monitor Coal Production and Quality

Coal Cutters monitor coal production levels and assess the quality of extracted coal. They ensure that production targets are met while maintaining adherence to quality standards. Their observations help optimize production processes and ensure the delivery of high-quality coal.

4. Maintain a Safe Work Environment

Safety is paramount in underground mining operations. Coal Cutters are responsible for maintaining a safe work environment. They follow established safety procedures, wear appropriate protective gear, and conduct regular inspections to identify and mitigate potential hazards.

Interview Tips

Preparing for a Coal Cutter interview requires thorough research and a comprehensive understanding of the role. Here are some key tips to help you ace the interview:

1. Research the Company and Industry

Before the interview, familiarize yourself with the mining company and the coal industry. Learn about their operations, safety practices, and industry trends. Demonstrating your knowledge shows enthusiasm and preparation.

2. Highlight Relevant Experience and Skills

Emphasize your experience operating coal cutting machines and your ability to maintain and repair them. Quantify your accomplishments, providing specific examples of successful coal extraction and equipment maintenance.

3. Demonstrate Safety Awareness

Safety is crucial in underground mining. Showcase your understanding of safety protocols, risk assessment, and emergency procedures. Highlight your commitment to maintaining a safe work environment.

4. Ask Thoughtful Questions

During the interview, ask insightful questions that demonstrate your interest and engagement. Inquire about the company’s safety culture, production goals, and opportunities for professional development.

Next Step:

Now that you’re armed with the knowledge of Coal Cutter interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Coal Cutter positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini