Feeling lost in a sea of interview questions? Landed that dream interview for Coal Drier Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Coal Drier Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

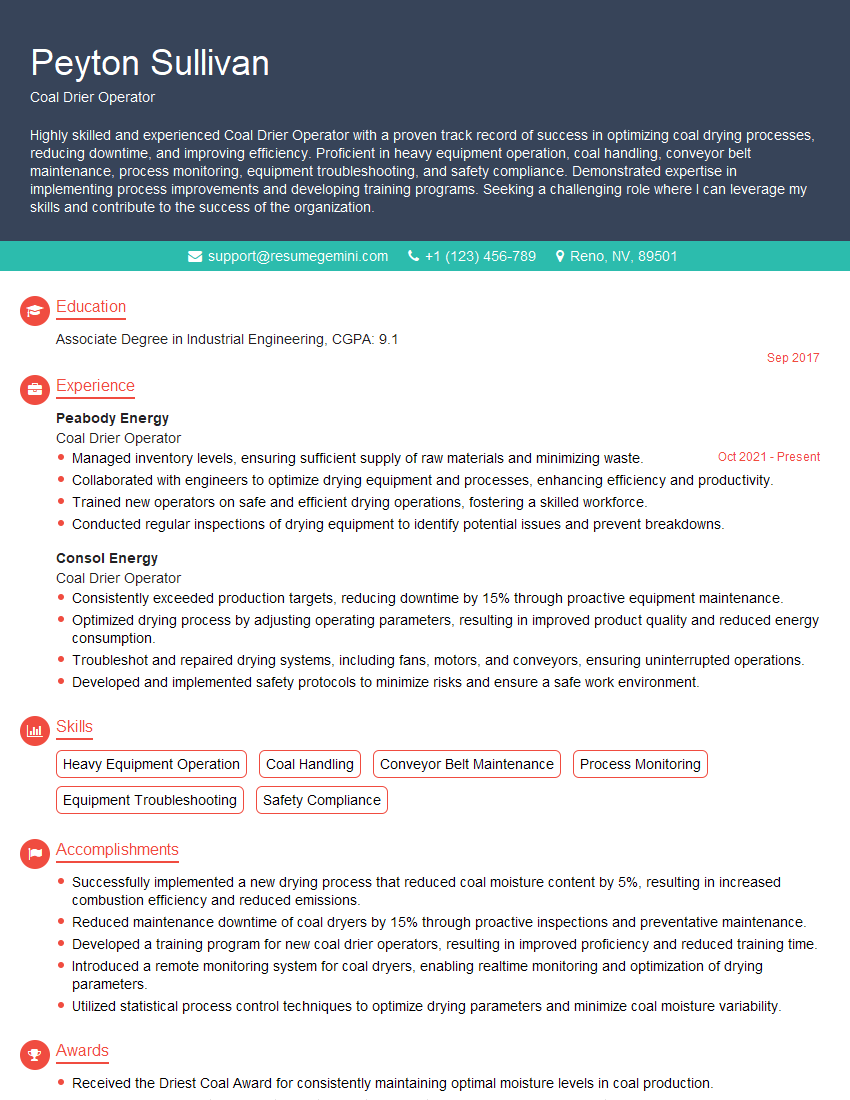

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Coal Drier Operator

1. What are the key responsibilities of a Coal Drier Operator?

As a Coal Drier Operator, my responsibilities include:

- Operating and monitoring coal drying equipment to remove moisture from coal

- Ensuring that the equipment is operating efficiently and safely

- Maintaining accurate records of the drying process

- Troubleshooting and resolving any problems that arise during the drying process

2. What are the different types of coal driers?

Convection Driers

- Uses hot air to remove moisture from coal

- Suitable for low-moisture coals

Contact Driers

- Uses heated surfaces to directly contact coal and remove moisture

- Suitable for high-moisture coals

Steam Tube Driers

- Uses steam to heat coal and remove moisture

- Suitable for a wide range of coal types

3. What are the important safety considerations for Coal Drier Operators?

Safety is paramount in my role as a Coal Drier Operator. I strictly adhere to the following safety protocols:

- Wearing appropriate personal protective equipment (PPE)

- Following lockout/tagout procedures before performing maintenance

- Being aware of the potential hazards of working with coal dust

- Understanding the emergency procedures for the drying facility

4. How do you ensure that the coal drying equipment is operating efficiently?

To ensure optimal efficiency, I:

- Monitor the equipment’s temperature, pressure, and flow rates

- Regularly inspect the equipment for wear and tear

- Make necessary adjustments to the equipment’s settings

- Keep the equipment clean and well-maintained

5. What are the common problems that can occur during the coal drying process?

Potential problems include:

- Clogging of the dryer

- Overheating of the coal

- Excessive moisture content in the dried coal

- Equipment breakdowns

6. How do you troubleshoot and resolve problems with the coal drying equipment?

My troubleshooting process involves:

- Identifying the problem and its potential causes

- Consulting with maintenance personnel or technical experts

- Implementing appropriate corrective actions

- Testing the equipment to ensure that the problem has been resolved

7. What are the quality control procedures for the dried coal?

To ensure the quality of the dried coal, I:

- Take samples of the dried coal and test its moisture content

- Inspect the dried coal for any foreign objects or contaminants

- Maintain accurate records of the quality control tests

8. What is the importance of coal drying in the coal industry?

Coal drying is essential because it:

- Reduces the moisture content of coal, making it easier to transport and handle

- Prevents coal from freezing during transportation

- Improves the combustion efficiency of coal

- Reduces the environmental impact of coal combustion

9. How do you stay up-to-date on the latest coal drying technologies?

I stay updated by:

- Reading industry publications and attending conferences

- Communicating with other Coal Drier Operators

- Consulting with equipment manufacturers

- Participating in training programs

10. How do you handle working in a high-pressure environment?

In high-pressure situations, I:

- Stay calm and focused

- Prioritize tasks and delegate responsibilities

- Communicate effectively with my team

- Take breaks when needed

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Coal Drier Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Coal Drier Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Coal Drier Operators hold the primary responsibility of operating and maintaining coal driers, ensuring the optimal and efficient drying of coal for downstream processes. Their core duties encompass monitoring and controlling the drying process, performing regular maintenance and repairs, and ensuring compliance with safety regulations and environmental standards.

1. Operate and Monitor Coal Drier

Coal Drier Operators shoulder the responsibility of operating and closely monitoring coal driers throughout their shifts. They meticulously control various parameters, including temperature, humidity, and airflow, to guarantee the coal meets the desired moisture content and quality specifications.

2. Perform Maintenance and Repairs

Beyond operation, Coal Drier Operators undertake regular maintenance and repair tasks to ensure the smooth functioning of the drier. They conduct routine inspections, identify potential issues, and perform necessary repairs or adjustments. By proactively addressing issues, they minimize downtime and maintain optimal performance.

3. Ensure Safety and Compliance

Coal Drier Operators serve as frontline enforcers of safety protocols and environmental regulations. They vigilantly monitor the work area for potential hazards, implement safety measures, and adhere to established guidelines. By prioritizing safety, they protect themselves, colleagues, and the environment.

4. Maintain Records and Reports

Coal Drier Operators assume the responsibility of maintaining accurate records and reports related to the drier’s operation and maintenance activities. They diligently document parameters, repairs, and any deviations from normal operating conditions. By preserving this data, they provide a valuable historical record for troubleshooting and continuous improvement efforts.

Interview Tips

Preparing for a Coal Drier Operator interview requires thorough research, practice, and a deep understanding of the role’s responsibilities. Here are some invaluable tips to help you ace the interview:

1. Research the Company and Industry

Thoroughly research the coal mining company you’re applying to, including its history, operations, and industry standing. Familiarize yourself with the specific coal drying process they employ. Understanding the company’s goals and the industry’s challenges will demonstrate your interest and preparedness.

2. Highlight Relevant Experience and Skills

Emphasize your prior experience operating and maintaining coal drying equipment or similar machinery. Showcase your technical aptitude, problem-solving abilities, and commitment to safety. If you possess certifications in drier operation or related fields, be sure to mention them.

3. Practice Common Interview Questions

Anticipate and prepare for potential interview questions. Practice answering questions related to your experience, technical knowledge, and safety awareness. Consider the STAR method (Situation, Task, Action, Result) to structure your responses effectively.

4. Dress Professionally and Arrive on Time

First impressions matter. Dress professionally and arrive punctually for your interview. Your attire and demeanor should convey respect for the interviewer and the opportunity. Punctuality demonstrates your reliability and commitment to the role.

5. Ask Informed Questions

At the end of the interview, take the opportunity to ask thoughtful questions. This shows your engagement and interest in the position. Prepare questions about the company’s safety protocols, environmental initiatives, or opportunities for professional development.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Coal Drier Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Coal Drier Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.