Feeling lost in a sea of interview questions? Landed that dream interview for Coal Handler but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Coal Handler interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

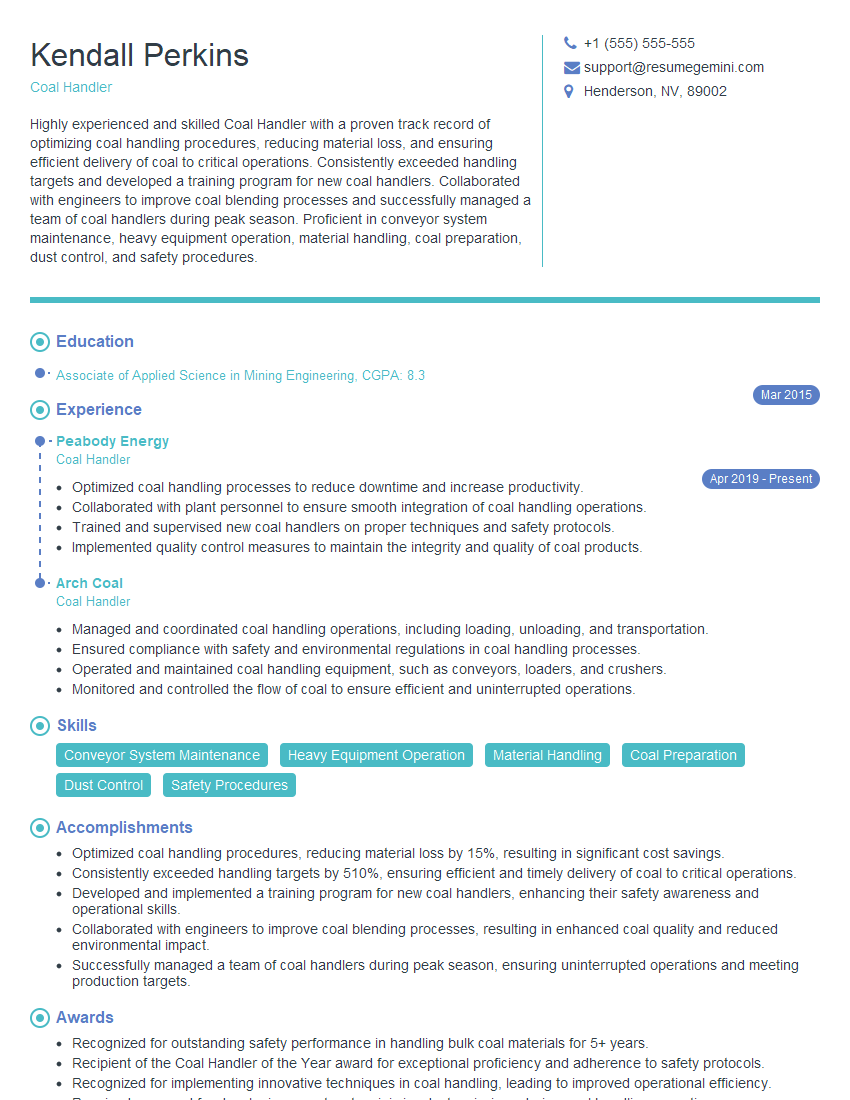

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Coal Handler

1. What are the different types of coal and their properties?

- Bituminous coal: This is the most common type of coal and is characterized by its high energy content and low moisture content.

- Anthracite coal: This is a hard, black coal with a high carbon content and a low moisture content.

- Lignite coal: This is a soft, brown coal with a high moisture content and a low energy content.

- Sub-bituminous coal: This is a coal that falls between bituminous and lignite coal in terms of its properties.

2. What are the different methods used to extract coal?

Surface mining

- Strip mining: This involves removing the overburden (soil and rock) overlying the coal seam and then extracting the coal.

- Open-pit mining: This involves digging a large pit in the ground and then extracting the coal.

Underground mining

- Room-and-pillar mining: This involves creating a network of rooms and pillars in the coal seam and then extracting the coal from the rooms.

- Longwall mining: This involves creating a long, narrow tunnel in the coal seam and then extracting the coal from the tunnel.

3. What are the different types of coal handling equipment?

- Conveyors: These are used to transport coal from one location to another.

- Loaders: These are used to load coal onto conveyors or into trucks or rail cars.

- Crushers: These are used to break down large pieces of coal into smaller pieces.

- Stackers: These are used to stack coal into piles.

- Reclaimers: These are used to remove coal from piles.

4. What are the safety precautions that must be taken when handling coal?

- Wear appropriate personal protective equipment (PPE), such as a hard hat, safety glasses, gloves, and a dust mask.

- Be aware of the potential for coal dust explosions and take steps to prevent them, such as using water sprays and keeping the area clean.

- Be aware of the potential for coal fires and take steps to prevent them, such as keeping the area free of debris and using fire extinguishers.

- Be aware of the potential for slips, trips, and falls and take steps to prevent them, such as keeping the area clean and free of obstacles.

5. What are the environmental regulations that must be followed when handling coal?

- The Clean Air Act: This act regulates air pollution, including emissions from coal-fired power plants.

- The Clean Water Act: This act regulates water pollution, including discharges from coal mines.

- The Resource Conservation and Recovery Act: This act regulates the disposal of solid waste, including coal ash.

6. What are the key quality parameters of coal and how are they measured?

- Moisture content: This is measured by drying a sample of coal and then weighing the remaining dry coal.

- Ash content: This is measured by burning a sample of coal and then weighing the remaining ash.

- Sulfur content: This is measured by analyzing a sample of coal for sulfur.

- Heating value: This is measured by burning a sample of coal and measuring the amount of heat produced.

7. What are the different types of coal blending and why is it done?

- Homogenization blending: This is done to create a coal with a consistent quality.

- Quality blending: This is done to create a coal with a specific quality, such as a high heating value or a low sulfur content.

- Cost blending: This is done to create a coal that is cost-effective.

8. What are the different types of coal storage and why is it important?

- Stockpiles: These are used to store large amounts of coal.

- Silos: These are used to store smaller amounts of coal.

- Hoppers: These are used to store coal that is being fed into a process.

- It is important to store coal properly to prevent it from losing its quality and to prevent the release of coal dust.

9. What are the different types of coal transportation and why is it important?

- Trucks: These are used to transport coal over short distances.

- Rail cars: These are used to transport coal over long distances.

- Conveyors: These are used to transport coal within a plant or facility.

- It is important to transport coal safely and efficiently to prevent spills and accidents.

10. What are the different types of coal utilization and why is it important?

- Power generation: Coal is used to generate electricity in power plants.

- Industrial use: Coal is used to power industrial boilers and furnaces.

- Residential use: Coal is used to heat homes and businesses.

- It is important to use coal efficiently to minimize waste and pollution.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Coal Handler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Coal Handler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Coal Handlers are responsible for the safe and efficient handling of coal, ensuring a consistent supply of fuel for power plants or industrial facilities. Their key responsibilities include:

1. Coal Handling Equipment Operation

Operate heavy machinery such as cranes, conveyor belts, and bulldozers to load, unload, transport, and stack coal.

2. Coal Quality Monitoring

Monitor the quality of coal received and ensure it meets specifications; conduct regular sampling and testing.

3. Inventory Management

Maintain accurate records of coal inventory, track deliveries, and coordinate with suppliers and customers.

4. Safety Compliance

Adhere to all safety regulations and procedures; wear appropriate protective gear and follow lockout/tagout protocols.

5. Equipment Maintenance

Perform routine maintenance on coal handling equipment to ensure optimal performance and prevent breakdowns.

6. Bunker Management

Manage coal bunkers, ensuring they are properly filled and maintained to prevent coal bridging or corrosion.

7. Dust Control

Implement and maintain dust control measures to minimize the spread of coal dust and protect the environment.

8. Communication and Coordination

Collaborate with other team members, supervisors, and external parties to coordinate coal handling operations.

Interview Tips

To prepare for a Coal Handler interview, consider the following tips:

1. Research the Company and Position

Understand the company’s operations, industry, and the specific job requirements. Highlight your relevant skills and experience.

2. Practice Common Interview Questions

Prepare answers to common interview questions, such as “Tell me about yourself,” “Why are you interested in this position,” and “What are your strengths and weaknesses.”

3. Showcase Your Technical Skills

Emphasize your proficiency in operating heavy machinery, coal quality monitoring, and inventory management. Provide specific examples of your experience.

4. Highlight Your Safety Awareness

Demonstrate your understanding of coal handling safety protocols and your commitment to adhering to them. Highlight any relevant training or certifications you hold.

5. Communicate Effectively

Articulate your thoughts clearly and concisely. Practice answering questions in a structured and professional manner.

6. Prepare Questions for the Interviewer

Prepare a few thoughtful questions to ask the interviewer, showing your interest and engagement in the position.

7. Dress Professionally

Make a good impression by dressing professionally and arriving on time for the interview.

8. Be Enthusiastic and Confident

Demonstrate your enthusiasm for the position and your confidence in your abilities. Maintain eye contact and engage in active listening.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Coal Handler, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Coal Handler positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.