Feeling lost in a sea of interview questions? Landed that dream interview for Coal Mill Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Coal Mill Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

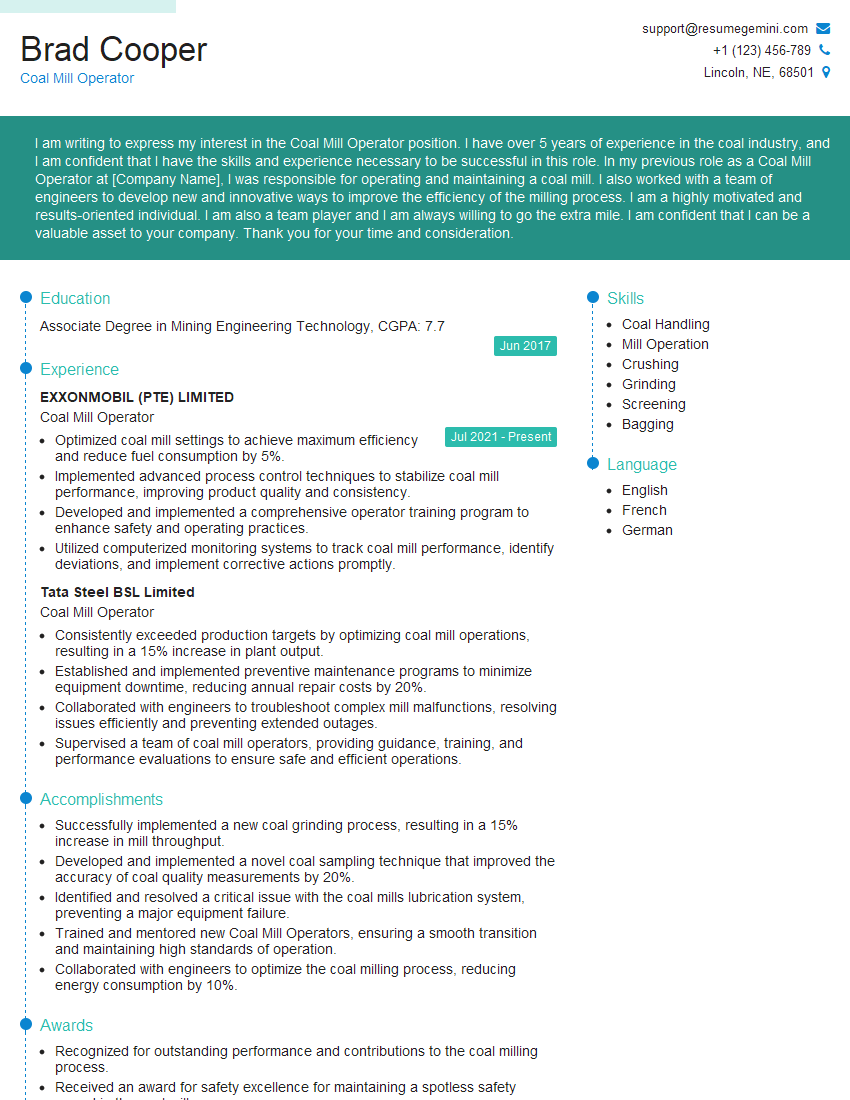

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Coal Mill Operator

1. What are the primary responsibilities of a Coal Mill Operator?

As a highly experienced Coal Mill Operator, I am proficient in:

- Monitoring and operating coal mills to ensure efficient grinding of coal to meet plant specifications.

- Adjusting mill settings, such as feed rate, airflow, and classifier speed, to optimize grinding performance.

- Maintaining the coal mill system, including equipment and instruments, to prevent breakdowns and ensure smooth operation.

2. Describe the process of starting up and shutting down a coal mill.

During Startup:

- Verify the mill is isolated and locked out.

- Check that all components are in good working order.

- Start the mill and gradually increase feed rate and airflow.

During Shutdown:

- Gradually reduce the feed rate and airflow.

- Stop the mill and isolate it from the system.

- Lock out and tag the mill for safety.

3. What types of maintenance tasks do you perform on coal mills?

I am responsible for performing preventive and corrective maintenance tasks, including:

- Lubrication of bearings and other moving parts.

- Replacement of worn or damaged components.

- Calibration of instruments and controls.

- Troubleshooting and resolving operational issues.

4. How do you ensure the coal mill is operating efficiently?

To optimize efficiency, I:

- Monitor mill performance indicators, such as fineness, moisture content, and power consumption.

- Adjust mill settings to maintain optimal conditions.

- Conduct regular inspections and maintenance to prevent breakdowns.

- Collaborate with other plant personnel to ensure a consistent supply of coal and proper mill operation.

5. What safety procedures are essential for Coal Mill Operators?

I strictly adhere to safety protocols, including:

- Wearing appropriate personal protective equipment.

- Following lockout/tagout procedures during maintenance.

- Being aware of the potential hazards of working with coal dust.

- Participating in regular safety training and drills.

6. Describe your experience in troubleshooting and resolving coal mill issues.

I possess strong troubleshooting skills and have successfully addressed various issues, such as:

- Identifying and replacing faulty components.

- Adjusting mill settings to correct grinding problems.

- Resolving coal flow issues and preventing blockages.

- Communicating with maintenance personnel to repair major breakdowns.

7. What is the importance of proper coal mill maintenance for plant operations?

Regular maintenance is crucial because it:

- Ensures reliable and efficient mill operation.

- Prevents costly breakdowns and production disruptions.

- Extends the lifespan of mill components.

- Supports optimal combustion and reduces emissions.

8. How do you stay up-to-date on industry best practices and technological advancements in coal milling?

I am committed to continuous learning and development. I:

- Attend industry conferences and workshops.

- Read technical journals and publications.

- Consult with vendors and manufacturers for updates.

- Participate in online training and certifications.

9. What are the key performance indicators (KPIs) you track to monitor the effectiveness of coal milling operations?

I track key KPIs, including:

- Mill availability and utilization rates.

- Coal fineness and moisture content.

- Power consumption and specific energy consumption.

- Preventive maintenance intervals and corrective maintenance frequency.

10. How do you handle working in a demanding and fast-paced environment as a Coal Mill Operator?

I thrive in demanding environments and possess:

- Excellent time management and multitasking abilities.

- A strong work ethic and dedication to meeting targets.

- The ability to work independently and as part of a team.

- Effective communication and problem-solving skills under pressure.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Coal Mill Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Coal Mill Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Coal Mill Operators are responsible for operating and maintaining coal mills, which grind coal into a fine powder for use in power plants. Their key responsibilities include:

1. Operating Coal Mills

Coal Mill Operators monitor and control the operation of coal mills, ensuring that they are operating efficiently and safely. This involves adjusting the mill’s settings, such as the feed rate and grinding speed, to optimize performance.

- Starting and stopping coal mills

- Monitoring mill parameters, such as temperature, pressure, and vibration

- Adjusting mill settings to optimize performance

2. Maintaining Coal Mills

Coal Mill Operators perform regular maintenance tasks to keep coal mills in good working condition. This includes inspecting and cleaning the mill’s components, such as the grinding elements and bearings, and replacing worn parts as needed.

- Inspecting and cleaning mill components

- Replacing worn parts

- Performing lubrication and other maintenance tasks

3. Troubleshooting Coal Mill Problems

Coal Mill Operators troubleshoot and resolve problems that occur with coal mills. This may involve identifying the source of the problem, such as a worn bearing or a clogged feed chute, and taking corrective action.

- Identifying and resolving mill problems

- Working with other plant personnel to resolve complex issues

- Maintaining records of mill maintenance and repairs

4. Ensuring Safety

Coal Mill Operators follow all safety procedures and regulations to ensure their own safety and the safety of others. This includes wearing appropriate safety gear, such as hard hats and gloves, and following proper lockout/tagout procedures when performing maintenance.

- Following safety procedures and regulations

- Wearing appropriate safety gear

- Performing lockout/tagout procedures

Interview Tips

Preparing for a Coal Mill Operator interview requires a combination of technical knowledge and communication skills. Here are some tips to help you ace your interview:

1. Research the Company and Position

Before the interview, take the time to research the company and the specific Coal Mill Operator position you are applying for. This will help you understand the company’s culture, values, and specific requirements for the role.

- Visit the company’s website and social media pages

- Read industry news and articles to stay up-to-date on trends

- Review the job description carefully and identify key qualifications

2. Highlight Your Skills and Experience

During the interview, be sure to highlight your skills and experience that are relevant to the Coal Mill Operator position. This includes your knowledge of coal mill operation, maintenance, and troubleshooting, as well as your safety and communication skills.

- Quantify your accomplishments using specific examples

- Use action verbs to describe your responsibilities

- Tailor your responses to the specific requirements of the job

3. Prepare for Technical Questions

Be prepared to answer technical questions about coal mill operation, maintenance, and troubleshooting. This may include questions about specific mill components, such as the grinding elements or bearings, as well as questions about safety procedures and regulations.

- Review the fundamentals of coal mill operation and maintenance

- Practice troubleshooting common mill problems

- Familiarize yourself with industry safety standards

4. Practice Your Communication Skills

Coal Mill Operators need to be able to communicate effectively with other plant personnel, including supervisors, engineers, and maintenance technicians. Be prepared to answer questions about your communication style and your ability to work in a team environment.

- Practice answering interview questions in a clear and concise manner

- Use examples to demonstrate your communication skills

- Be prepared to discuss your experience working in a team environment

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Coal Mill Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!