Are you gearing up for a career in Coal Miner? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Coal Miner and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

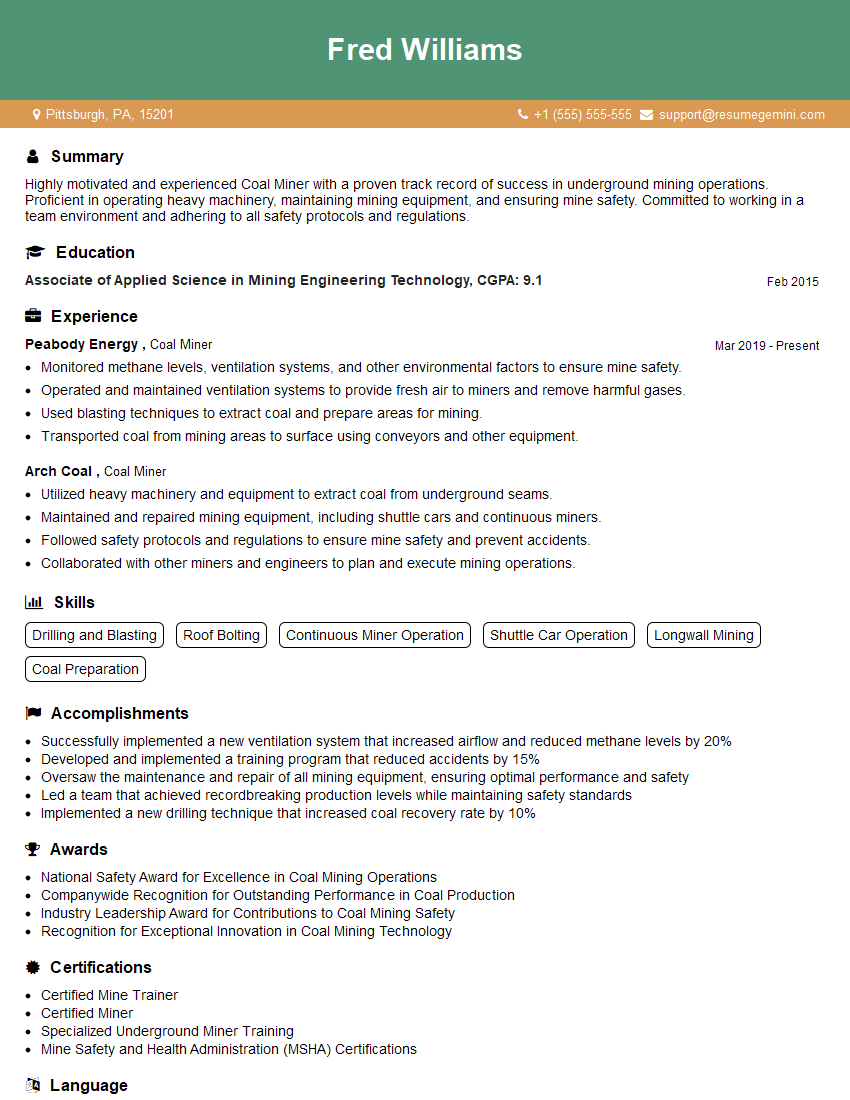

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Coal Miner

1. Explain the steps involved in operating a continuous miner?

Continuous miners are complex machines and operating them requires training and experience. These are the steps involved in operating a continuous miner:

- Conduct a pre-shift inspection of the machine to ensure it is in good working condition.

- Position the miner at the face of the coal seam.

- Set the cutting head to the desired cutting depth.

- Start the cutting head and advance the miner into the coal seam.

- Monitor the machine’s performance and make adjustments as needed.

- Unload the coal from the miner’s conveyor onto a shuttle car.

- Perform post-shift maintenance on the machine.

2. What are the safety precautions that must be taken when working with a continuous miner?

General safety precautions

- Wear appropriate personal protective equipment, including a hard hat, safety glasses, and gloves.

- Be aware of your surroundings and be cautious of moving equipment.

- Never operate a continuous miner if you are not trained and authorized to do so.

- Follow all safety procedures and regulations.

Specific safety precautions for operating a continuous miner

- Inspect the machine before each shift to ensure it is in good working condition.

- Position the miner at the face of the coal seam before starting the cutting head.

- Set the cutting head to the desired cutting depth and advance the miner into the coal seam at a controlled rate.

- Monitor the machine’s performance and make adjustments as needed.

- Unload the coal from the miner’s conveyor onto a shuttle car in a safe and controlled manner.

- Perform post-shift maintenance on the machine to ensure it is ready for the next shift.

3. How do you maintain a continuous miner?

Continuous miners require regular maintenance to ensure they are operating safely and efficiently. Some of the maintenance tasks that must be performed on a continuous miner include:

- Inspecting the machine before each shift to ensure it is in good working condition.

- Lubricating the machine’s moving parts.

- Replacing worn or damaged parts.

- Performing electrical and mechanical checks.

- Following all maintenance procedures and regulations.

4. What are the different types of roof bolting machines and how are they used?

There are two main types of roof bolting machines: manual and self-advancing. Manual roof bolting machines are operated by a single miner, who inserts the bolts into the roof and tightens them using a wrench. Self-advancing roof bolting machines are more automated and can insert and tighten bolts without the need for a miner to be in the immediate vicinity of the machine.

Roof bolting machines are used to install roof bolts into the roof of a mine to support the roof and prevent it from collapsing. Roof bolting is an important safety measure in underground mines, as it helps to prevent roof falls, which can be a major cause of injuries and fatalities.

5. What safety precautions must be taken when using a roof bolting machine?

When using a roof bolting machine, it is important to take the following safety precautions:

- Wear appropriate personal protective equipment, including a hard hat, safety glasses, and gloves.

- Be aware of your surroundings and be cautious of moving equipment.

- Never operate a roof bolting machine if you are not trained and authorized to do so.

- Follow all safety procedures and regulations.

- Inspect the roof bolting machine before each shift to ensure it is in good working condition.

- Position the roof bolting machine correctly before starting to install bolts.

- Insert and tighten the bolts according to the manufacturer’s instructions.

- Never attempt to remove a bolt that has already been tightened.

- Perform post-shift maintenance on the roof bolting machine to ensure it is ready for the next shift.

6. How do you troubleshoot a roof bolting machine?

If a roof bolting machine is not working properly, it is important to troubleshoot the problem and make repairs as soon as possible. Some of the most common problems that can occur with roof bolting machines include:

- The machine is not starting.

- The machine is not inserting the bolts correctly.

- The machine is not tightening the bolts correctly.

- The machine is leaking hydraulic fluid.

- The machine is making strange noises.

If you are experiencing any of these problems, it is important to refer to the manufacturer’s instructions for troubleshooting and repair procedures.

7. What are the different types of ventilation systems used in underground mines?

There are two main types of ventilation systems used in underground mines: natural ventilation and mechanical ventilation.

Natural ventilation relies on the natural movement of air to circulate air through the mine. This type of ventilation is only effective in small mines with good airflow.

Mechanical ventilation uses fans to circulate air through the mine. This type of ventilation is more effective in large mines with poor airflow.

8. What are the safety precautions that must be taken when working in a poorly ventilated area?

When working in a poorly ventilated area, it is important to take the following safety precautions:

- Wear a respirator that is approved by the Mine Safety and Health Administration (MSHA).

- Be aware of the signs and symptoms of oxygen deficiency, such as dizziness, nausea, and vomiting.

- Never work alone in a poorly ventilated area.

- Follow all safety procedures and regulations.

9. How do you communicate with other miners when working underground?

There are a variety of ways to communicate with other miners when working underground, including:

- Hand signals

- Verbal communication

- Radios

- Electronic communication devices

The most effective way to communicate with other miners will vary depending on the specific circumstances.

10. What are the emergency procedures for a mine fire?

In the event of a mine fire, it is important to follow the following emergency procedures:

- Report the fire to your supervisor immediately.

- Evacuate the mine in a calm and orderly manner.

- Follow the designated escape routes.

- Do not use elevators.

- Do not go back into the mine for any reason.

Once you have evacuated the mine, you should report to the designated assembly point and wait for further instructions.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Coal Miner.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Coal Miner‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Coal Miners work in underground or surface mines to extract coal for power generation and other industrial purposes. Their primary tasks include:

1. Coal Extraction

Using heavy machinery such as continuous miners, roof bolters, and shuttle cars, coal miners extract coal from seams underground or in surface mines.

2. Maintaining Mine Safety

Ensuring a safe work environment is crucial. Coal miners monitor roof conditions, ventilation systems, and gas levels to mitigate potential hazards such as roof collapses, explosions, and asphyxiation.

3. Operating Equipment and Machinery

Proficiently operating and maintaining mining equipment is essential. Coal miners must have a comprehensive understanding of machinery, its functionality, and safety protocols.

4. Blasting and Explosives Handling

In some cases, miners may be involved in controlled blasting to break up coal seams. They must adhere to strict safety guidelines for handling explosives and maintaining blast sites.

5. Coal Processing and Transportation

Once coal is extracted, miners assist in processing it by removing impurities and preparing it for transportation. They also operate conveyor belts and other equipment to transport coal to the surface or processing facilities.

Interview Tips

Preparing thoroughly for a Coal Miner interview can significantly increase your chances of success. Here are some essential tips:

1. Research the Industry and Company

Demonstrate your knowledge of the coal mining industry, its key players, and the specific company you’re applying to. Research their operations, safety record, and career opportunities.

2. Highlight Relevant Skills and Experience

Emphasize your skills in operating heavy machinery, maintaining safety protocols, and working in hazardous environments. Showcase any previous experience in coal mining or related industries.

3. Prepare for Physical and Technical Questions

Be prepared to answer questions about your physical fitness, endurance, and ability to work in confined spaces. You may also face technical questions about mining equipment and safety procedures.

4. Practice Behavioral Interview Questions

Behavioral interview questions focus on your past experiences and behaviors. Prepare examples of how you’ve handled safety challenges, worked effectively in teams, and solved problems under pressure.

5. Dress Professionally and Arrive Punctually

First impressions matter. Dress professionally and arrive for your interview on time to demonstrate your respect for the interviewer and the company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Coal Miner interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!