Are you gearing up for an interview for a Coal Screener position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Coal Screener and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

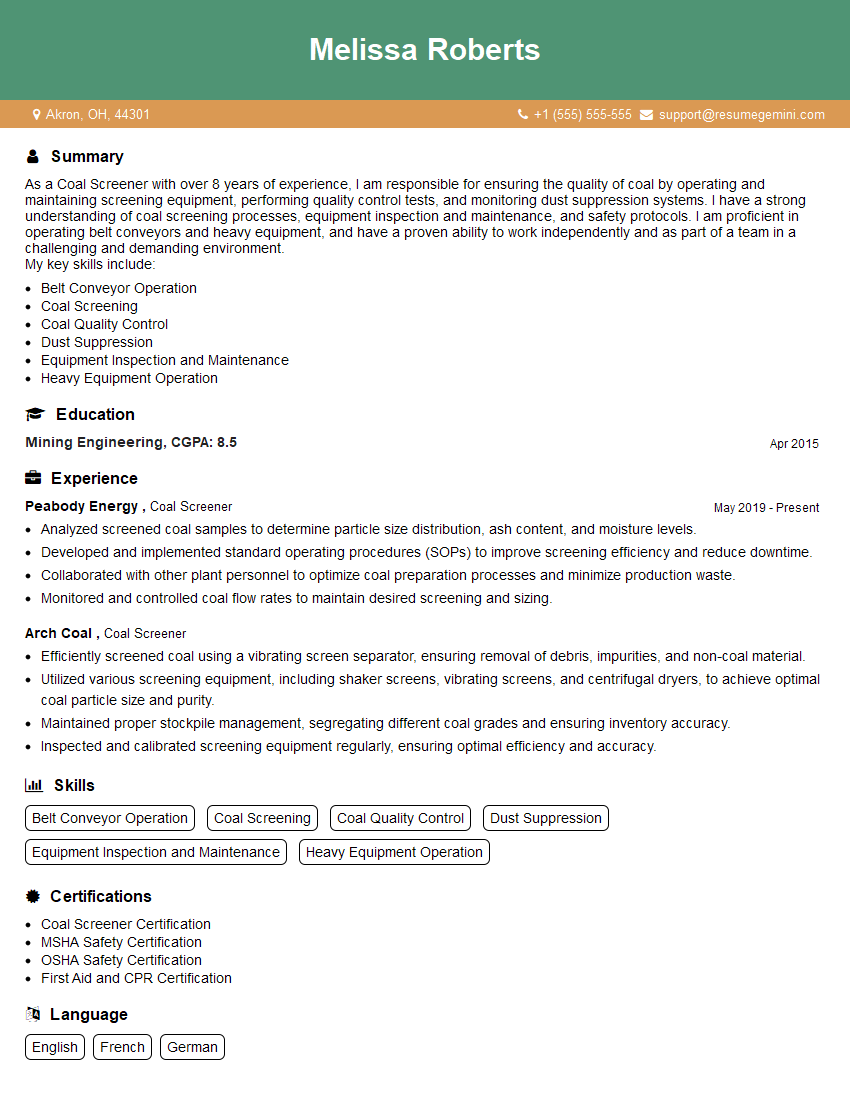

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Coal Screener

1. Describe the process of coal screening.

- Coal screening is the process of separating raw coal into different sizes using screens or sieves.

- The primary purpose of screening is to remove impurities, such as dirt, rocks, and other non-combustible materials, from the coal.

- Screening also helps improve the quality of the coal by separating it into different size fractions, which can be used for different purposes.

2. What are the different types of coal screens?

- There are two main types of coal screens: stationary and vibrating.

- Stationary screens are typically used for larger pieces of coal, while vibrating screens are used for screening smaller pieces.

- Screens can also be classified based on the size of the openings, such as fine screens, medium screens, and coarse screens.

3. What factors affect the efficiency of coal screening?

- The size and shape of the coal

- The moisture content of the coal

- The type of screen and the size of the openings

- The speed and angle of the screen

4. What are the common problems associated with coal screening?

- Clogging or blinding of the screen openings due to excessive moisture or fine particles

- Wear and tear of the screen surface

- Vibrational issues in vibrating screens

- Improper sizing or separation of coal

5. How do you ensure the accuracy and consistency of coal screening operations?

- Regular calibration and maintenance of the screens

- Using automatic control systems to regulate the speed, angle, and other parameters of the screening process

- Implementing quality control measures, such as sampling and testing of screened coal

6. What safety precautions should be taken when operating coal screening equipment?

- Wearing appropriate personal protective equipment (PPE), such as gloves, eye protection, and respiratory masks

- Ensuring proper guarding and fencing around screening machinery

- Following lockout/tagout procedures before performing maintenance or repairs

7. What is the role of a Coal Screener in the coal mining and processing industry?

- Operating and maintaining coal screening equipment

- Adjusting and calibrating screens to achieve desired separation efficiency

- Monitoring and controlling coal flow through the screening process

- Ensuring that screening operations meet quality and production targets

- Troubleshooting and resolving any issues related to coal screening

8. How do you handle situations where there are variations in the quality or characteristics of the coal being screened?

- Adjusting the screening parameters, such as screen speed or angle, to accommodate different coal properties

- Consulting with supervisors or engineers to determine the best course of action

- Implementing modifications or upgrades to the screening equipment to improve efficiency

9. What are the key maintenance tasks involved in keeping coal screening equipment in good working condition?

- Regular cleaning and inspection of screens

- Checking and tightening bolts and fittings

- Lubricating moving parts

- Replacing worn or damaged components

- Performing vibration analysis to detect any imbalances or issues

10. How do you stay up-to-date on the latest technologies and best practices in coal screening?

- Attending industry conferences and workshops

- Reading technical journals and publications

- Consulting with equipment manufacturers and suppliers

- Participating in online forums and discussions

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Coal Screener.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Coal Screener‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities of a Coal Screener

A Coal Screener is an essential part of the coal mining process, responsible for ensuring the quality of the coal being sent to market. Their primary duties include:

1. Screening and Separating Coal

Coal Screeners operate machinery that separates coal from impurities and undesirable materials, such as rocks, dirt, and other foreign objects. They adjust the screens to ensure that the coal meets the required size and quality standards.

- Calibrating and maintaining screening equipment

- Monitoring the flow of coal and inspecting for contaminants

2. Quality Control

Coal Screeners are responsible for ensuring the quality of the coal by conducting regular inspections and tests. They identify any abnormalities or inconsistencies in the coal’s composition or appearance.

- Collecting samples for analysis

- Interpreting test results and adjusting equipment accordingly

3. Equipment Maintenance

Coal Screeners perform routine maintenance on screening equipment, including cleaning, lubrication, and minor repairs. They also assist with major overhauls and repairs as needed.

- Lubricating moving parts and replacing worn components

- Inspecting equipment for potential issues and reporting any concerns

4. Safety and Compliance

Coal Screeners follow strict safety protocols and adhere to all applicable regulations and standards. They ensure that the screening process is conducted in a safe and environmentally responsible manner.

- Wearing appropriate protective gear and following safety procedures

- Reporting any accidents or hazards to supervisors

Interview Preparation Tips for Coal Screeners

To ace an interview for a Coal Screener position, candidates should follow these essential tips:

1. Research the Company and Industry

Before the interview, research the coal mining company and the industry as a whole. This will demonstrate your interest and knowledge of the field. Look into the company’s production methods, safety record, and environmental practices.

- Visit the company’s website and social media pages

- Read industry news and articles

2. Practice Answering Common Interview Questions

Prepare for the interview by practicing answering common questions related to your skills, experience, and knowledge of the coal screening process. Some of the most frequently asked questions include:

- Tell us about your experience in coal screening

- How do you ensure the quality of the coal you screen?

- What safety measures do you follow in your work?

- What are your goals and aspirations for this role?

3. Highlight Your Relevant Skills and Experience

Emphasize your relevant skills and experience in your resume and during the interview. Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact. For example, you could highlight your ability to increase screening efficiency by a certain percentage or reduce downtime by a specific number of hours.

- Use action verbs and provide concrete examples

- Tailor your responses to the specific requirements of the job

4. Dress Professionally and Arrive on Time

First impressions matter, so dress professionally for the interview. Arrive on time and be prepared to answer questions about your experience and qualifications. Be polite and respectful to everyone you meet, including the receptionist and other employees.

- Choose clothing that is clean, pressed, and appropriate for a professional setting

- Arrive 10-15 minutes early to allow for any unexpected delays

5. Follow Up and Thank the Interviewer

After the interview, follow up with the interviewer to thank them for their time and reiterate your interest in the position. You could also ask for feedback on your performance and inquire about the next steps in the hiring process.

- Send a thank-you note within 24 hours of the interview

- Reiterate your key qualifications and how you would contribute to the company

Next Step:

Now that you’re armed with the knowledge of Coal Screener interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Coal Screener positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini