Are you gearing up for a career in Coat Joiner? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Coat Joiner and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

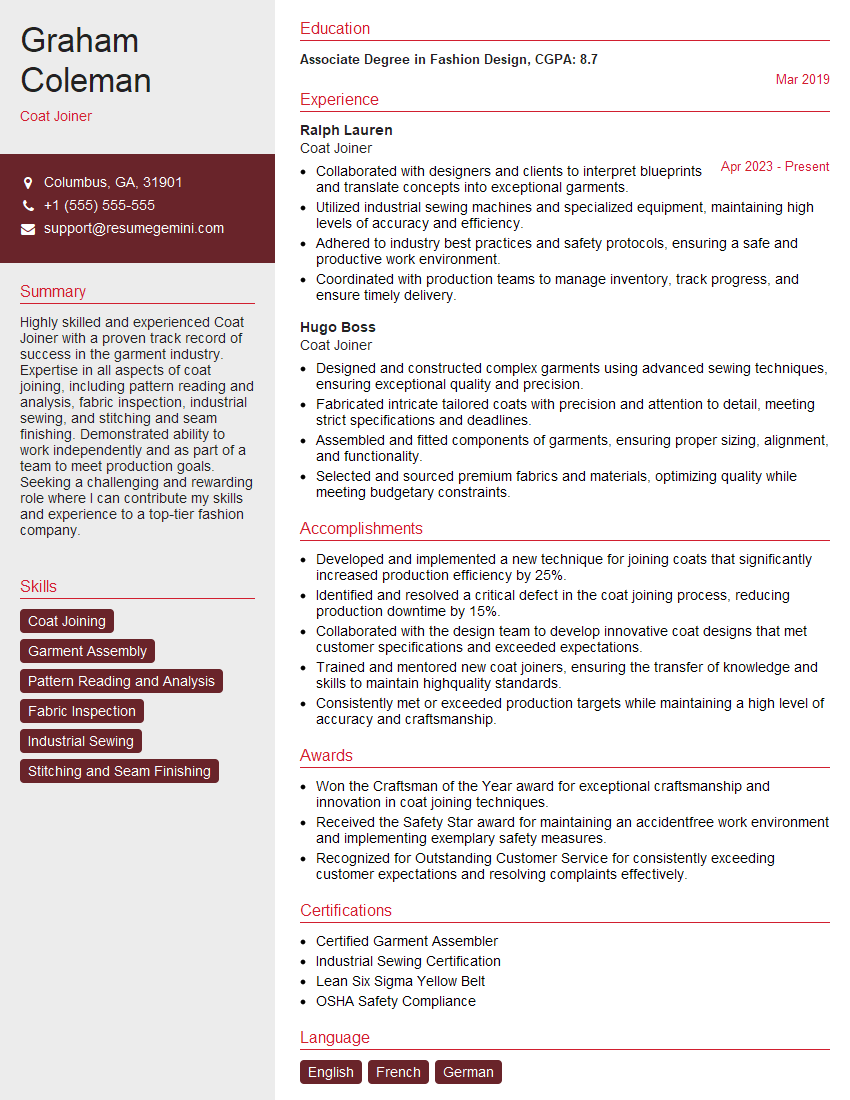

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Coat Joiner

1. What are the different types of joints used in coat construction and when would you use each type?

- Butt Joint: This joint is used to join two pieces of fabric that are the same size. It is a strong and durable joint, but it can be difficult to keep the fabric aligned.

- Lap Joint: This joint is used to join two pieces of fabric that are different sizes. It is a strong and durable joint, but it can be more bulky than a butt joint.

- Topstitch Joint: This joint is used to join two pieces of fabric together and create a decorative topstitch. It is a strong and durable joint, but it can be more time-consuming to create than other joints.

- French Seam: This joint is used to create a clean and finished seam. It is a strong and durable joint, but it can be more time-consuming to create than other joints.

2. How do you ensure that the coat will fit the customer properly?

To ensure that the coat will fit the customer properly, I take the following steps:

- Take the customer’s measurements, including their chest, waist, hips, and length.

- Compare the customer’s measurements to a standard size chart to determine the best size for the coat.

- Make any necessary adjustments to the coat to ensure that it fits the customer’s body shape.

3. What are the different types of fabrics used in coat construction and what are the advantages and disadvantages of each type?

- Wool: Wool is a natural fiber that is warm, durable, and wrinkle-resistant. However, it can be expensive and it can be itchy for some people.

- Cashmere: Cashmere is a soft, luxurious fiber that is warmer than wool. However, it is also more expensive than wool and it can be more difficult to care for.

- Leather: Leather is a durable and water-resistant material that is often used for coats. However, it can be expensive and it can be difficult to work with.

- Cotton: Cotton is a natural fiber that is breathable and comfortable to wear. However, it is not as warm as wool or cashmere and it can wrinkle easily.

- Synthetic fibers: Synthetic fibers are often used in coats because they are durable, wrinkle-resistant, and affordable. However, they can be less breathable than natural fibers and they can sometimes feel less luxurious.

4. What are the different types of closures used in coat construction and what are the advantages and disadvantages of each type?

- Buttons: Buttons are a classic and versatile closure that can be used on a variety of coats. They are easy to use and they can be replaced if they are lost or damaged.

- Zippers: Zippers are a quick and easy closure that is often used on casual coats. They are durable and they can be easily repaired if they break.

- Velcro: Velcro is a hook-and-loop closure that is often used on children’s coats. It is easy to use and it is very durable.

- Snaps: Snaps are a fast and easy closure that is often used on lightweight coats. They are durable and they can be easily replaced if they are lost or damaged.

5. How do you handle customer complaints?

When handling customer complaints, I follow these steps:

- Listen to the customer’s complaint and try to understand their point of view.

- Apologize for any inconvenience or dissatisfaction that the customer has experienced.

- Offer a solution to the problem, such as a refund, exchange, or repair.

- Follow up with the customer to make sure that they are satisfied with the resolution.

6. What are the safety regulations that you must follow when working as a coat joiner?

- Wear appropriate safety gear, such as gloves, safety glasses, and a dust mask.

- Use sharp tools carefully and always keep them in good condition.

- Be aware of your surroundings and take precautions to avoid accidents.

- Follow all safety instructions provided by your employer.

7. What is your favorite thing about working as a coat joiner?

My favorite thing about working as a coat joiner is that I get to create beautiful and functional garments that people will enjoy wearing for years to come. I also enjoy the challenge of working with different fabrics and materials and finding creative ways to solve problems.

8. What are your career goals?

My career goal is to become a master coat joiner. I want to continue to learn and develop my skills so that I can create the highest quality coats possible. I also want to share my knowledge and skills with others and help them to achieve their own career goals.

9. Why are you interested in this particular position?

I am interested in this particular position because it is a great opportunity for me to learn from experienced coat joiners and to develop my skills in a professional setting. I am also excited about the opportunity to work on a variety of different coats and to help customers find the perfect coat for their needs.

10. What are your strengths and weaknesses?

My strengths as a coat joiner include my attention to detail, my strong work ethic, and my ability to learn quickly. I am also a creative problem solver and I am always looking for ways to improve my skills.

My weakness is that I can sometimes be a perfectionist and I can be hard on myself when I don’t meet my own expectations. However, I am always willing to learn from my mistakes and I am always striving to improve.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Coat Joiner.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Coat Joiner‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Coat Joiners are responsible for joining pieces of coat material together to create finished coats. They use a variety of tools and techniques to complete their work, including sewing machines, glue guns, and hand tools.

1. Prepare materials

Coat Joiners start by preparing the materials they will be using. This includes cutting the coat material to the correct size and shape, and applying any necessary adhesives or other materials.

- Measure and cut the coat material according to the specified dimensions.

- Apply glue or other adhesives to the edges of the material and join them together.

- Use hand tools to smooth and shape the seams, and ensure a snug fit.

2. Assemble the coat

Once the materials are prepared, Coat Joiners begin assembling the coat. This involves sewing the pieces of material together, using a variety of stitches and techniques.

- Sew the shoulder seams and side seams, using a machine or hand-sewing techniques.

- Insert the sleeves and sew them into place, ensuring correct alignment and fit.

- Attach the collar, cuffs, and any other embellishments, as per the design specifications.

3. Finish the coat

Once the coat is assembled, Coat Joiners finish it by pressing the seams, adding any final details, and inspecting the finished product.

- Press the seams flat and smooth, using a steam iron or a press.

- Add buttons, zippers, or other hardware, as required by the design.

- Inspect the finished coat for any defects or imperfections, and make any necessary corrections.

4. Maintain equipment

In addition to their production responsibilities, Coat Joiners are also responsible for maintaining their equipment. This includes cleaning and lubricating sewing machines, and replacing needles and other parts as needed.

- Clean and lubricate sewing machines and other equipment regularly.

- Inspect equipment for any damage or wear, and report any issues to supervisors.

- Replace needles, thread, and other consumables as needed, to ensure optimal performance.

Interview Tips

Preparing thoroughly for your Coat Joiner interview can increase your chances of success. Here are some tips to help you ace the interview:

1. Research the company and the position

Take the time to learn about the company you’re applying to and the specific position you’re interested in. This will help you answer questions intelligently and show that you’re genuinely interested in the opportunity.

- Visit the company’s website to learn about their history, mission, and products or services.

- Review the job description carefully and identify the key skills and experience that the employer is looking for.

2. Practice your answers to common interview questions

There are a number of common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It’s helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

- Prepare a brief and engaging introduction that highlights your relevant skills and experience.

- For the “Why are you interested in this position?” question, explain how your skills and interests align with the job requirements and the company’s goals.

3. Be prepared to discuss your experience and skills

The interviewer will want to know about your previous experience and how it has prepared you for the Coat Joiner position. Be ready to discuss your skills in detail, and provide specific examples of how you’ve used them in your past work.

- Highlight your experience in joining coat materials, using different techniques and tools.

- Describe your knowledge of different types of fabrics and materials used in coat making.

4. Ask questions

Asking thoughtful questions at the end of the interview shows that you’re engaged and interested in the position. It also gives you an opportunity to learn more about the company and the role.

- Inquire about the company’s production processes and quality control measures.

- Ask about the training and development opportunities available to employees.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Coat Joiner interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!