Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Coater Adjuster position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

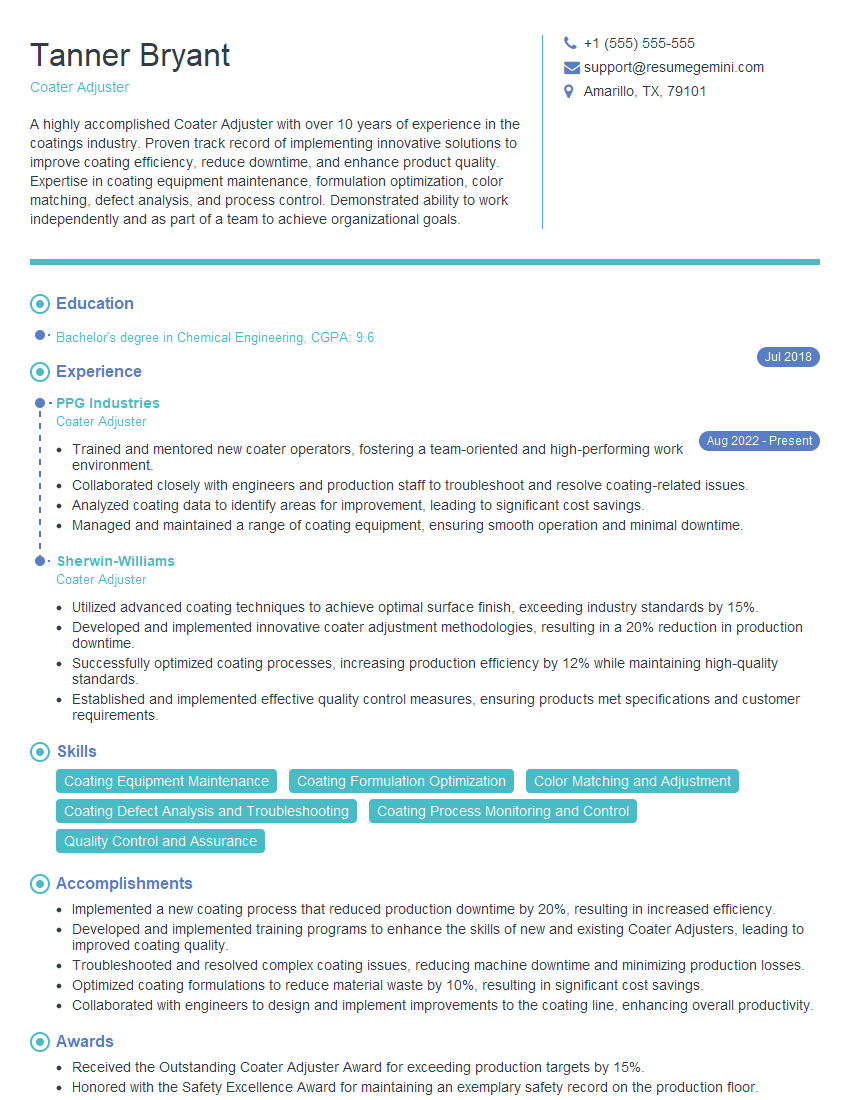

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Coater Adjuster

1. What are the different types of coater machines and their applications?

- Knife-over-roll coating: Applies a thin, even layer of coating to a substrate using a blade that scrapes excess coating from the roller.

- Reverse-roll coating: Submerges the substrate in a coating bath and then passes it through a set of rollers to remove excess coating.

- Curtain coating: Flows the coating material over the substrate, creating a uniform film as the substrate passes through the curtain.

- Gravure coating: Transfers the coating material from an engraved cylinder to the substrate, allowing for precise control of coating thickness.

2. Explain the process of setting up and calibrating a coater machine.

Pre-Setup

- Review job instructions and gather necessary materials.

- Ensure the machine and workspace are clean and free of debris.

Setup

- Install the appropriate rollers and doctor blades.

- Adjust the nip gap to the desired coating thickness.

- Set the speed and tension controls.

Calibration

- Run a test sample and measure the coating thickness.

- Adjust the machine settings as necessary to achieve the desired coating weight.

- Verify the calibration against the job specifications.

3. How do you troubleshoot common coating defects?

- Streaking: Can be caused by uneven coating application, improper adhesive selection, or contamination.

- Orange peel: Occurs when the coating surface is rough, often due to rapid drying or excessive humidity.

- Pinholing: Small holes in the coating, caused by trapped air or contaminants.

- Cracking: Caused by excessive stress on the coating, such as temperature changes or incompatible materials.

4. What is the importance of controlling coating viscosity?

- Affects the flowability, coverage, and thickness of the coating.

- Too high viscosity can lead to uneven coating, while too low viscosity can result in excessive runoff.

- Monitoring and adjusting viscosity ensures consistent coating quality and performance.

5. Describe the safety precautions when operating a coater machine.

- Wear appropriate personal protective equipment (PPE).

- Follow lockout/tagout procedures before performing maintenance.

- Ensure the machine is properly grounded to prevent electrical hazards.

- Handle solvents and other chemicals with care.

- Maintain a clean and organized work area.

6. What role does coating thickness play in product performance?

- Affects the physical properties, such as strength, durability, and adhesion.

- Influences the optical properties, such as color, gloss, and transparency.

- Controls the release properties, such as slip resistance and anti-stick behavior.

7. How do you stay up-to-date on the latest coating technologies and advancements?

- Attend industry conferences and trade shows.

- Read technical journals and articles.

- Participate in online forums and discussion groups.

- Network with other professionals in the field.

8. What is your experience with using different types of coating materials?

- Describe the properties and applications of various coating materials, such as paints, adhesives, and lubricants.

- Highlight your understanding of how coating materials interact with different substrates.

- Mention your experience in selecting and recommending the best coating material for specific applications.

9. Explain the importance of maintaining a clean coating line.

- Prevents contamination of the coating material.

- Reduces the risk of defects and ensures product quality.

- Extends the lifespan of the coating equipment.

- Creates a safe and healthy work environment.

10. Describe your problem-solving approach when encountering coating-related issues.

- Identify the problem: Gather data, observe the process, and consult with colleagues.

- Analyze the causes: Consider possible factors such as equipment, materials, or environmental conditions.

- Generate solutions: Brainstorm ideas to address the root cause of the problem.

- Implement and test: Implement the most promising solution and monitor its effectiveness.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Coater Adjuster.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Coater Adjuster‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Coater Adjusters are responsible for the proper functioning of coating machines to ensure the production of high-quality coated products. Their responsibilities include monitoring machine settings, adjusting coating formulations, and performing quality control tests on the finished products.

1. Machine Operation

Coater Adjusters are responsible for setting up and operating coating machines, making sure that they run efficiently and produce high-quality products.

- Set up and adjust coating machines according to specifications.

- Monitor machine operation and make adjustments as needed to maintain production quality.

- Identify and troubleshoot machine problems, and perform minor repairs.

2. Formulation Adjustment

Coater Adjusters are responsible for adjusting coating formulations to meet the desired product specifications. This may involve changing the ratios of different ingredients, adding or removing additives, and adjusting the temperature and viscosity of the coating.

- Adjust coating formulations to achieve desired product properties.

- Experiment with different formulations to improve coating quality.

- Follow standard operating procedures for mixing and applying coatings.

3. Quality Control

Coater Adjusters are responsible for performing quality control tests on the finished products to ensure that they meet the desired specifications. This may involve testing the thickness, appearance, and adhesion of the coating.

- Conduct quality control tests on finished products.

- Interpret test results and take corrective action as needed.

- Maintain records of quality control data.

Interview Tips

Preparing for a job interview can be daunting, but by following these tips, you can increase your chances of success.

1. Research the Company and the Position

Take some time to learn about the company you’re applying to, as well as the specific position you’re interested in. This will help you understand the company’s culture, values, and goals, and will also give you a better idea of what the job entails.

- Visit the company’s website.

- Review the job description carefully.

- Speak to people who work at the company.

2. Practice Your Answers to Common Interview Questions

There are a few common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It’s a good idea to practice your answers to these questions ahead of time so that you can deliver them confidently and concisely.

- Use the STAR method to answer behavioural questions.

- Prepare examples that highlight your skills and experience.

- Practice your answers out loud.

3. Dress Professionally and Arrive on Time

First impressions matter, so it’s important to dress professionally for your interview. You should also arrive on time, as being late can be seen as disrespectful.

- Dress in a suit or business casual attire.

- Be punctual.

- Be polite and respectful to everyone you meet.

4. Be Yourself and Be Enthusiastic

The most important thing is to be yourself and be enthusiastic about the position. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. And if you’re not excited about the position, it will be difficult to convince the interviewer that you’re the right person for the job.

- Be honest about your skills and experience.

- Show your enthusiasm for the position.

- Be confident in your abilities.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Coater Adjuster interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!