Are you gearing up for an interview for a Coater Associate position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Coater Associate and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

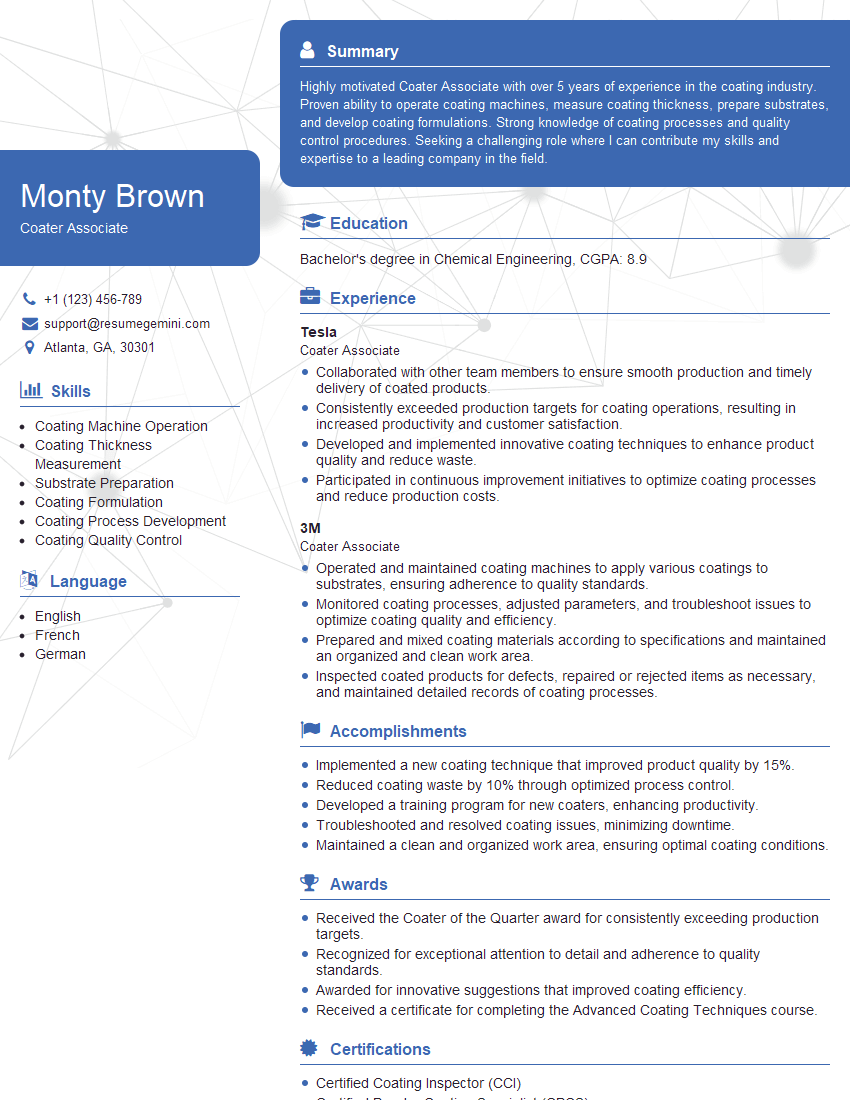

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Coater Associate

1. Can you explain the process of roller coating?

Roller coating is a technique used to apply a thin, uniform layer of liquid to a substrate. The substrate is passed between two rollers, one of which is coated with the liquid. The liquid is transferred from the coated roller to the substrate, forming a thin film. The film is then dried or cured to achieve the desired properties.

2. What are the different types of roller coating machines?

Gravity fed

- The liquid is fed onto the roller by gravity, and then transferred to the substrate.

- This type of machine is simple and inexpensive, but it can only produce a thin film.

Pump fed

- The liquid is pumped onto the roller, which then transfers it to the substrate.

- This type of machine can produce a thicker film than a gravity fed machine, but it is more expensive.

Reverse roll

- The substrate is passed between two rollers, one of which is coated with the liquid.

- The liquid is transferred from the coated roller to the substrate, and then the excess liquid is removed by the second roller.

- This type of machine can produce a very thin, uniform film.

3. What are the factors that affect the thickness of the coating?

- Viscosity of the liquid

- Speed of the rollers

- Gap between the rollers

- Temperature of the liquid

- Type of substrate

4. What are the different types of coatings that can be applied using roller coating?

- Paints

- Inks

- Adhesives

- Sealants

- Lubricants

5. What are the advantages of using roller coating?

- High speed

- Uniformity of coating

- Good edge definition

- Low cost

6. What are the disadvantages of using roller coating?

- Limited film thickness

- Can only be used on flat substrates

- Can be difficult to apply coatings to complex shapes

7. What are the safety precautions that must be taken when using a roller coating machine?

- Wear appropriate safety gear, including gloves, safety glasses, and a lab coat.

- Make sure the machine is properly grounded.

- Keep the work area clean and free of debris.

- Never reach into the machine while it is running.

- Follow all manufacturer’s instructions for safe operation.

8. What are the maintenance procedures that must be performed on a roller coating machine?

- Clean the rollers regularly.

- Inspect the rollers for wear and damage.

- Lubricate the bearings regularly.

- Check the electrical system for any loose connections.

- Follow all manufacturer’s instructions for maintenance.

9. What is the difference between a roll coater and a knife coater?

- Roll coaters use rollers to apply the coating, while knife coaters use a blade to spread the coating.

- Roll coaters can produce a thicker coating than knife coaters.

- Knife coaters can produce a more uniform coating than roll coaters.

10. What are the different types of substrates that can be coated using a roll coater?

- Paper

- Plastic

- Metal

- Glass

- Wood

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Coater Associate.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Coater Associate‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Coater Associates play a crucial role in the manufacturing process, ensuring the smooth and efficient application of coatings to various substrates. Their key responsibilities include:

1. Coating Application

Utilize specialized equipment and techniques to apply coatings to materials with precision and accuracy. Ensure proper coverage, thickness, and uniformity.

2. Coating Material Preparation

Prepare and mix coating materials according to specifications. Monitor viscosity, temperature, and other parameters to ensure optimal coating performance.

3. Equipment Maintenance and Calibration

Inspect, clean, and maintain coating equipment regularly. Calibrate and adjust equipment to ensure accurate and consistent coating results.

4. Quality Control

Conduct quality checks on coated products to ensure adherence to specifications. Identify and rectify any defects or inconsistencies promptly.

5. Safety and Environmental Compliance

Follow established safety protocols and environmental regulations. Wear appropriate protective gear and handle hazardous materials safely.

Interview Tips

To ace the interview for a Coater Associate position, consider the following preparation tips and interview hacks:

1. Research the Company and Role

Gather thorough information about the company’s business, industry, and specific coating processes. Demonstrate a genuine interest in the role and how your skills align with the company’s needs.

2. Highlight Relevant Experience and Skills

Emphasize your experience in coating application, material preparation, equipment maintenance, and quality control. Quantify your accomplishments with specific examples to showcase your impact.

3. Practice Your Answers

Prepare for potential interview questions by practicing your responses. Focus on highlighting your technical skills, attention to detail, and commitment to quality.

4. Dress Professionally and Arrive on Time

Make a positive first impression by dressing appropriately and arriving punctually. This demonstrates your respect for the interviewer and the company.

5. Ask Thoughtful Questions

At the end of the interview, ask insightful questions to show your engagement and interest in the role. This can demonstrate your curiosity and desire to learn more about the company and the industry.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Coater Associate interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!