Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Coater position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

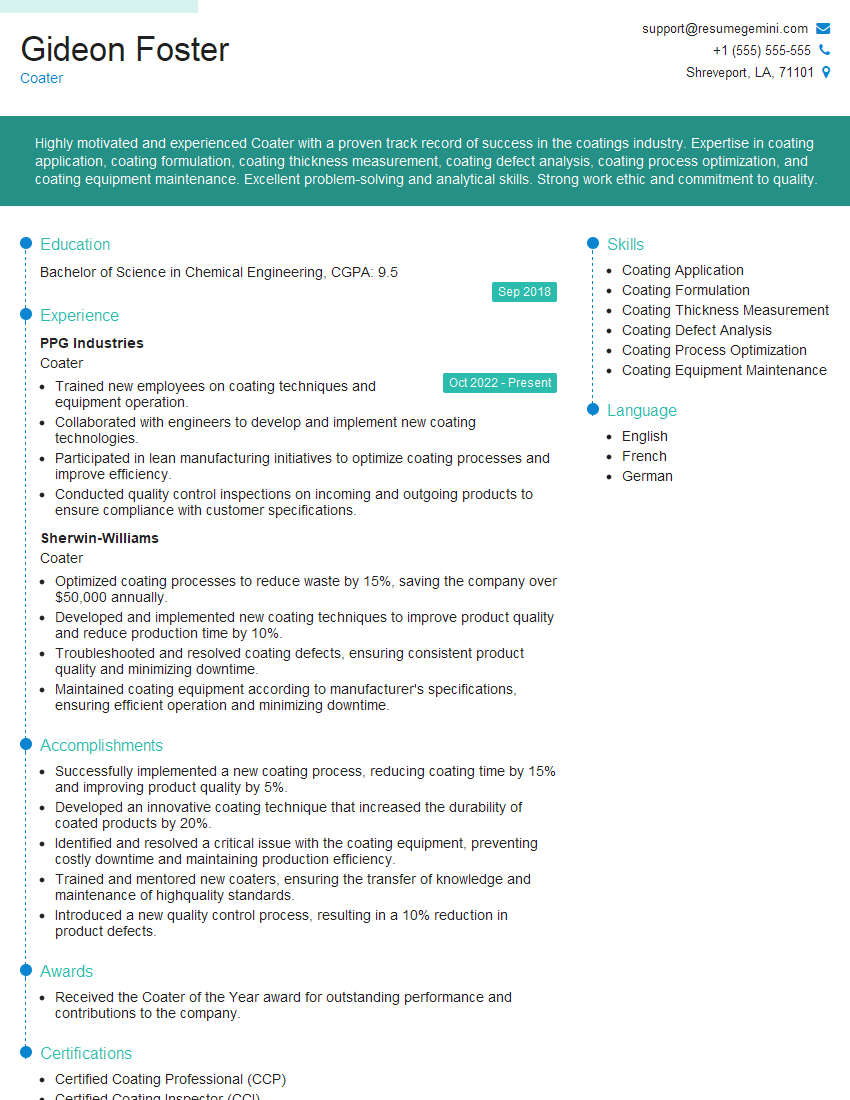

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Coater

1. What are the different types of coating processes you have experience in?

I have experience in a variety of coating processes, including:

- Dip coating

- Spin coating

- Spray coating

- Electroplating

- Electrophoretic deposition

- Chemical vapor deposition

- Physical vapor deposition

2. What are the key factors to consider when selecting a coating process?

Substrate compatibility

- The coating process must be compatible with the substrate material.

- Some processes, such as electroplating, can only be used on conductive substrates.

Coating properties

- The coating must have the desired properties, such as thickness, hardness, and corrosion resistance.

- The coating process must be able to produce a coating with the desired properties.

Cost and efficiency

- The coating process must be cost-effective and efficient.

- Some processes, such as chemical vapor deposition, can be expensive and time-consuming.

3. What are the challenges associated with coating complex geometries?

- Complex geometries can make it difficult to achieve uniform coating thickness.

- Some areas of the substrate may be inaccessible to the coating material.

- The coating process may need to be modified to accommodate the complex geometry.

4. What are the different methods for measuring coating thickness?

- Micrometers

- Coating thickness gauges

- Cross-sectioning

- Scanning electron microscopy

5. What are the most common defects in coatings?

- Pin holes

- Cracks

- Blisters

- Delamination

6. What are the causes of coating defects?

- Substrate preparation

- Coating application

- Curing

- Environmental conditions

7. How do you prevent coating defects?

- Proper substrate preparation

- Correct coating application

- Proper curing

- Control of environmental conditions

8. What are the different types of coating equipment?

- Coating machines

- Spray guns

- Electroplating tanks

- Chemical vapor deposition reactors

- Physical vapor deposition systems

9. What are the safety precautions that must be taken when working with coatings?

- Wear appropriate personal protective equipment (PPE)

- Ventilate the work area

- Handle chemicals properly

- Dispose of waste properly

10. What are the latest trends in coating technology?

- Nanotechnology

- Green coatings

- Self-healing coatings

- Antibacterial coatings

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Coater.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Coater‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Coaters are crucial personnel in the manufacturing industry, responsible for applying protective or decorative coatings to various surfaces. Their primary tasks involve ensuring the accuracy and quality of the coating process while adhering to safety regulations.

1. Coating Application

Coaters are entrusted with the task of applying coatings to a wide range of materials, including metals, plastics, fabrics, and paper. They skillfully operate coating machines to apply consistent and uniform layers, ensuring that the desired thickness and coverage are achieved.

2. Equipment Maintenance

Coaters are responsible for maintaining the equipment they use, including coating machines, spray guns, and related tools. They conduct routine inspections, perform cleaning and adjustments, and identify potential issues to prevent downtime and ensure optimal performance.

3. Quality Control

Coaters play a pivotal role in maintaining high standards by monitoring and inspecting the quality of the coated products. They conduct visual and physical tests to identify any defects, such as uneven coating, streaks, or imperfections. They work closely with quality control teams to ensure that all coated products meet the required specifications.

4. Safety Compliance

Coaters are committed to upholding safety regulations and procedures to create a safe work environment. They wear appropriate personal protective equipment (PPE), follow safety protocols, and handle hazardous materials responsibly.

Interview Preparation Tips

Preparing for a Coater interview requires a combination of technical knowledge, attention to detail, and a commitment to safety. Here are some essential interview preparation tips to help you shine:

1. Research the Industry and Company

Take the time to gather information about the manufacturing industry, current industry trends, and the company you’re applying to. This knowledge will enable you to engage in meaningful discussions, demonstrate your understanding of the field, and impress the interviewers.

2. Highlight Your Technical Skills

Coating processes involve technical expertise. Emphasize your proficiency in operating coating machines, understanding different coating materials, and troubleshooting equipment issues. Showcase your ability to apply coatings to various surfaces, ensuring quality and accuracy.

3. Demonstrate Attention to Detail

Coaters must possess a keen eye for detail to identify defects and ensure the consistency of coated products. Highlight your meticulous and dokładne approach to your work. Provide examples of how you ensure precision and accuracy in your coating practices.

4. Emphasize Safety Awareness

Safety is paramount in the manufacturing industry. Express your commitment to safety by explaining your understanding of safety protocols, PPE usage, and hazardous materials handling. Describe your proactive approach to maintaining a safe work environment.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Coater interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.