Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Coater Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

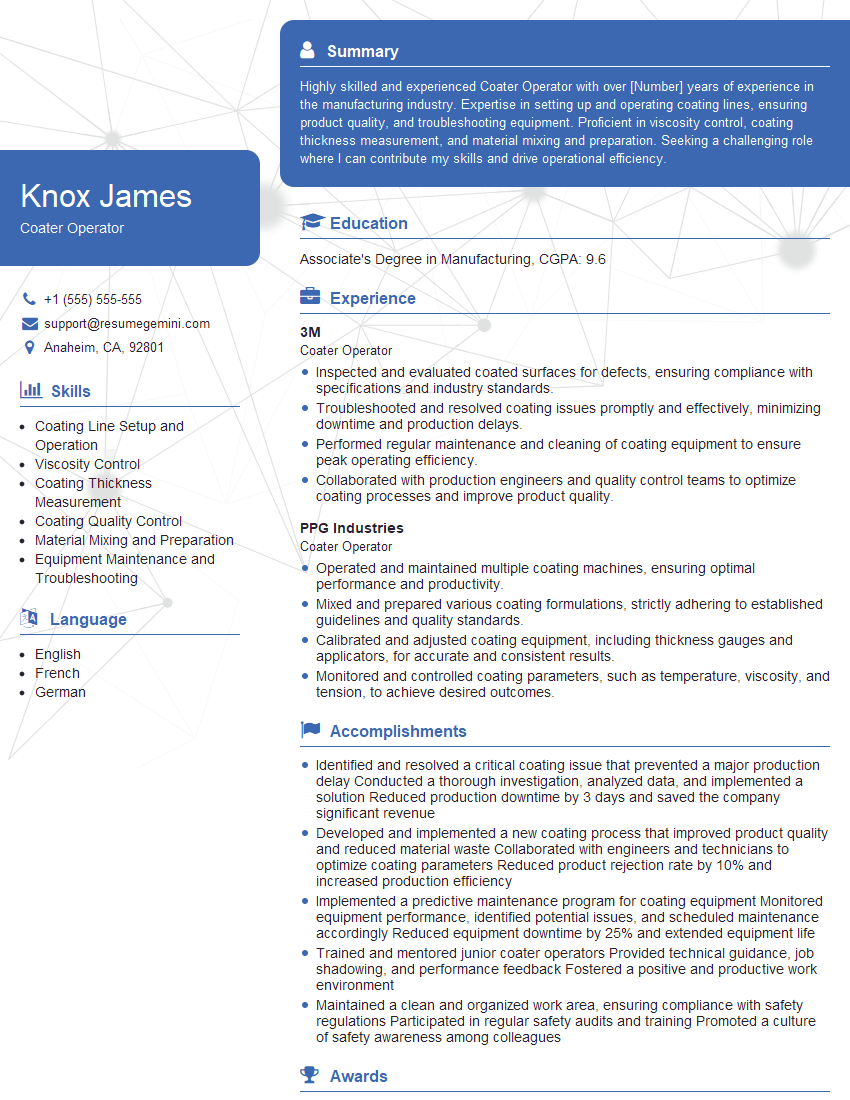

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Coater Operator

1. Describe the process of coating paper using a blade coater?

The blade coating process involves the following steps:

- The paper web is unwound from the reel and fed into the coating machine.

- The coating material is applied to the paper web by a blade.

- The coated paper web is dried and calendared.

2. What are the different types of coating materials used in blade coating?

Solvent-Based Coatings

- These coatings contain a solvent that evaporates during the drying process.

- They offer good adhesion and flexibility.

Water-Based Coatings

- These coatings contain water as the main solvent.

- They are more environmentally friendly than solvent-based coatings.

Emulsion Coatings

- These coatings contain a mixture of water and solvent.

- They offer good adhesion and flexibility.

3. What are the key operating parameters in blade coating?

The key operating parameters in blade coating include:

- Coating speed

- Blade pressure

- Blade angle

- Coating thickness

4. How do you control the coating thickness in blade coating?

The coating thickness can be controlled by adjusting the following parameters:

- Blade pressure

- Blade angle

- Coating speed

5. What are the common defects in blade coating and how do you correct them?

Common defects in blade coating include:

- Streaks: Caused by uneven blade pressure or coating thickness.

- Bubbles: Caused by trapped air in the coating.

- Pinholes: Caused by air bubbles that burst during the drying process.

These defects can be corrected by adjusting the operating parameters or by using different coating materials.

6. How do you troubleshoot a blade coater?

Troubleshooting a blade coater involves the following steps:

- Identify the problem.

- Check the operating parameters.

- Inspect the coating material.

- Clean the coater.

- Calibrate the coater.

7. What are the safety precautions that you should follow when operating a blade coater?

- Wear protective clothing and equipment.

- Keep the work area clean and free of debris.

- Follow the manufacturer’s operating instructions.

- Never operate the coater unattended.

8. What are the maintenance tasks that you should perform on a blade coater?

- Clean the coater regularly.

- Lubricate the moving parts.

- Inspect the blade for wear and tear.

- Calibrate the coater regularly.

9. What are the different types of blade coaters?

- Single-blade coaters

- Double-blade coaters

- Airfoil coaters

- Reverse roll coaters

10. What are the advantages and disadvantages of blade coating?

Advantages

- High production speeds

- Good coating quality

- Versatile coating process

Disadvantages

- High capital cost

- Complex operation

- Can produce defects

11. What is the role of a coater operator in a paper mill?

A coater operator is responsible for operating and maintaining a blade coater.

- They monitor the coating process and make adjustments as needed.

- They inspect the coated paper for defects.

- They clean and maintain the coater.

- They follow safety procedures to ensure a safe work environment.

12. What are the qualifications and experience required to be a coater operator?

- High school diploma or equivalent

- 2-3 years of experience operating a blade coater

- Knowledge of coating materials and processes

- Good troubleshooting skills

- Strong safety orientation

13. What are the career advancement opportunities for a coater operator?

- Coater supervisor

- Production manager

- Quality control manager

- Coating technician

14. What is the salary range for a coater operator?

The salary range for a coater operator varies depending on experience and location. In the United States, the average salary for a coater operator is around $50,000 per year.

15. What are the benefits of working as a coater operator?

- Competitive salary and benefits

- Stable work environment

- Opportunities for advancement

- Job satisfaction

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Coater Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Coater Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Coater Operators play a vital role in the production process of various manufacturing industries. Their key responsibilities involve operating and maintaining coating equipment, ensuring efficient and consistent application of coatings onto surfaces.

1. Machine Operation and Maintenance

Coater Operators are responsible for setting up, operating, and maintaining coating machines. They ensure proper machine functionality, perform routine maintenance, and troubleshoot any issues that may arise during the coating process.

- Configure and adjust machine settings to achieve desired coating thickness and uniformity.

- Monitor machine performance continuously, identifying and addressing potential problems promptly.

- Perform preventive maintenance tasks, such as lubrication, cleaning, and replacing worn parts, to optimize machine longevity.

2. Coating Application

Coater Operators are responsible for preparing and applying coatings to surfaces according to specified parameters. They follow established procedures and use appropriate equipment to ensure accurate and consistent coating application.

- Prepare surfaces by cleaning and treating them to enhance coating adhesion.

- Select and mix coating materials based on specific requirements and application methods.

- Apply coatings using spray, dip, or other techniques, ensuring proper thickness and coverage.

3. Quality Control and Inspection

Coater Operators are responsible for ensuring the quality of coated products. They perform inspections, using various tools and techniques, to verify that coatings meet the required specifications.

- Conduct visual inspections to identify defects, such as uneven coating, bubbles, or scratches.

- Use measuring tools and gauges to check coating thickness, adhesion, and other properties.

- Document inspection results and report any non-conformances to supervisors or quality control personnel.

4. Safety and Environmental Compliance

Coater Operators work with potentially hazardous materials and equipment. They are responsible for adhering to safety regulations and environmental guidelines to ensure a safe and compliant work environment.

- Wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and respirators.

- Follow established safety protocols for handling and disposing of chemicals and hazardous waste.

- Monitor the work area for potential hazards and take necessary precautions to prevent accidents.

Interview Tips

Preparing for a Coater Operator interview requires a combination of technical knowledge and effective communication skills. Here are some tips to help you ace the interview:

1. Research the Company and Position

Before the interview, thoroughly research the company and the specific Coater Operator position you are applying for. Learn about their industry, products, and values to demonstrate your interest and alignment with their goals.

2. Highlight Your Technical Skills

Emphasize your technical skills and experience in operating and maintaining coating equipment. Provide specific examples of your ability to troubleshoot and resolve machine issues, ensuring optimal performance.

3. Showcase Your Quality Control Experience

Highlight your experience in quality control and inspection procedures. Explain how you ensure the quality of coated products, including the use of measuring tools, gauges, and other inspection techniques.

4. Demonstrate Safety Awareness

Coater Operators work with hazardous materials and equipment. Explain your understanding of safety protocols and your commitment to maintaining a safe and compliant work environment.

5. Practice Your Communication Skills

Interviews are not just about technical expertise; communication skills are equally important. Practice answering common interview questions clearly and concisely, providing specific examples to support your responses.

6. Dress Professionally and Arrive Punctually

First impressions matter. Dress professionally and arrive on time for your interview. This demonstrates your respect for the company and the interview process.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Coater Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!