Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Coating and Baking Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

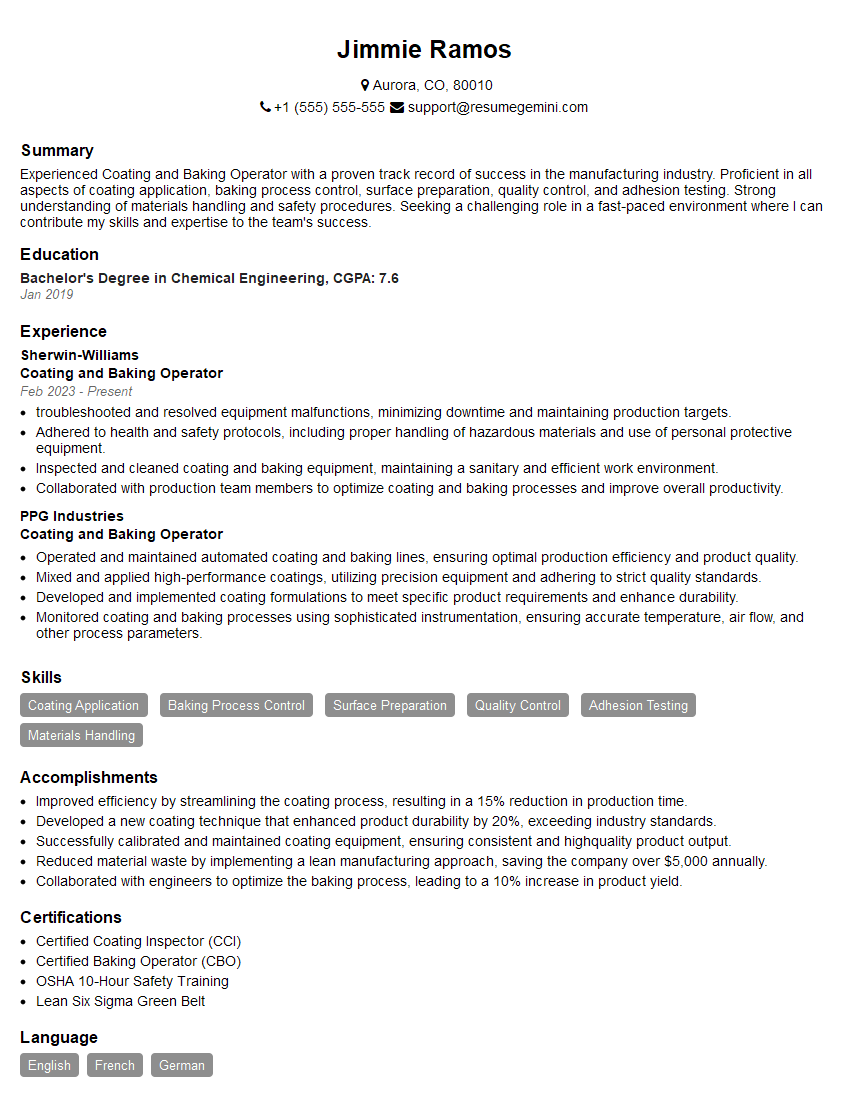

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Coating and Baking Operator

1. Describe the coating process you are most familiar with?

In my previous role, I was responsible for electrostatic spray coating, which involves applying a coating material to a surface using an electrostatic charge. The process involves several steps, including surface preparation, application of the coating material, and curing.

2. What are the different types of baking processes used in the industry?

Convection Baking

- Uses hot air to circulate around the product, transferring heat evenly.

- Suitable for products that require a consistent and uniform bake.

Radiant Baking

- Employs infrared or microwave radiation to heat the product directly.

- Provides rapid heating and is ideal for products with specific heating requirements.

Hybrid Baking

- Combines convection and radiant baking to achieve optimal results.

- Allows for precise control over the baking process and is suitable for a wide range of products.

3. How do you troubleshoot and resolve common coating and baking defects?

Defects such as blistering, peeling, or discoloration can occur during the coating and baking process. I approach troubleshooting by:

- Identifying the root cause of the defect, whether it’s related to the coating material, application, or baking conditions.

- Implementing corrective measures such as adjusting the coating parameters, improving surface preparation, or altering the baking cycle.

4. What are the safety precautions and regulations that must be followed in a coating and baking operation?

I am well-versed in industry safety protocols, including:

- Proper handling and storage of flammable and hazardous materials.

- Use of personal protective equipment (PPE) such as gloves, respirators, and safety glasses.

- Maintaining a clean and organized work area to prevent accidents.

5. What are the quality control procedures involved in coating and baking?

To ensure product quality, I adhere to established quality control procedures, which include:

- Inspecting raw materials and finished products.

- Maintaining accurate records of coating and baking parameters.

- Conducting regular equipment calibration.

6. How do you handle and dispose of solvents and waste generated during the coating and baking process?

Proper handling and disposal of solvents and waste are crucial. I ensure that:

- Spent solvents are collected and disposed of according to environmental regulations.

- Waste materials are properly segregated and disposed of.

- Regular cleaning and maintenance of equipment minimize waste generation.

7. How do you optimize the coating and baking process for both efficiency and quality?

Optimizing the process involves:

- Selecting the appropriate coating materials and equipment.

- Establishing optimal coating and baking parameters.

- Continuously monitoring and adjusting the process to ensure consistent results.

8. What is your experience with lean manufacturing techniques, such as Six Sigma or Kaizen?

I have a strong understanding of lean manufacturing techniques, particularly Six Sigma. I have applied Six Sigma methodologies to:

- Identify and eliminate process inefficiencies.

- Reduce waste and improve overall productivity.

- Continuously improve the coating and baking process.

9. How do you stay up-to-date with the latest advancements in coating and baking technologies?

I believe in continuous learning and development. I stay informed about advancements through:

- Attending industry conferences and webinars.

- Reading technical articles and journals.

- Networking with professionals in the field.

10. In a previous role, describe a time when you successfully resolved a major coating or baking issue.

In my previous role, we encountered a problem with excessive bubbling during the baking process. I investigated the issue and identified that the coating material was not being properly mixed. I adjusted the mixing procedure, and the problem was resolved, resulting in a significant improvement in product quality.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Coating and Baking Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Coating and Baking Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Coating and Baking Operators play a vital role in manufacturing processes that involve applying protective or decorative coatings to various components or products. Their key responsibilities include:

1. Coating Preparation

Preparing coating materials by mixing specified ingredients, ensuring proper viscosity and other quality parameters.

- Following established coating procedures and mixing ratios.

- Adjusting coating properties to meet specific product requirements.

2. Coating Application

Applying coatings to components or products using various techniques, such as dipping, spraying, or electroplating.

- Operating and maintaining coating equipment, including ovens, spray booths, and conveyors.

- Controlling coating thickness, consistency, and adherence.

3. Baking Process

Baking coated components or products to cure and set the coating.

- Monitoring and adjusting baking temperature, time, and other parameters.

- Ensuring proper ventilation and safety during baking operations.

4. Quality Control

Inspecting coated products for defects, such as blistering, cracking, or uneven coverage.

- Adhering to quality standards and specifications.

- Reporting non-conforming products for corrective action.

5. Maintenance and Housekeeping

Cleaning and maintaining coating equipment, ovens, and work areas.

- Performing routine maintenance tasks to prevent equipment malfunctions.

- Maintaining a clean and organized work environment.

Interview Tips

Preparing for a job interview as a Coating and Baking Operator requires a combination of technical knowledge and articulation skills. Here are some tips to help candidates ace the interview:

1. Research the Industry and Company

Familiarize yourself with the specific industry and company you are applying to. Understand their products, processes, and quality standards.

- Visit the company website and read about their mission, values, and recent developments.

- Identify key trends and challenges in the coating and baking industry.

2. Highlight Relevant Experience and Skills

Emphasize your experience in coating and baking operations, including the techniques and equipment you have worked with.

- Quantify your accomplishments, such as reducing coating waste or improving product quality.

- Highlight your attention to detail and commitment to safety.

3. Demonstrate Technical Knowledge

Be prepared to answer questions about coating materials, application methods, and baking processes.

- Explain the different types of coatings and their properties.

- Describe the factors that affect coating performance and how to control them.

4. Practice Your Communication Skills

Articulate your thoughts clearly and concisely. Demonstrate your ability to communicate effectively with colleagues and supervisors.

- Prepare for common interview questions, such as “Tell me about yourself” or “Why are you interested in this role?”.

- Ask thoughtful questions to show your interest and engagement.

5. Dress Professionally and Be Punctual

First impressions matter. Dress professionally and arrive on time for your interview.

- Wear clean, pressed clothing that is appropriate for a manufacturing environment.

- Arrive a few minutes early to show your respect and punctuality.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Coating and Baking Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!