Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Coating and Embossing Unit Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Coating and Embossing Unit Operator so you can tailor your answers to impress potential employers.

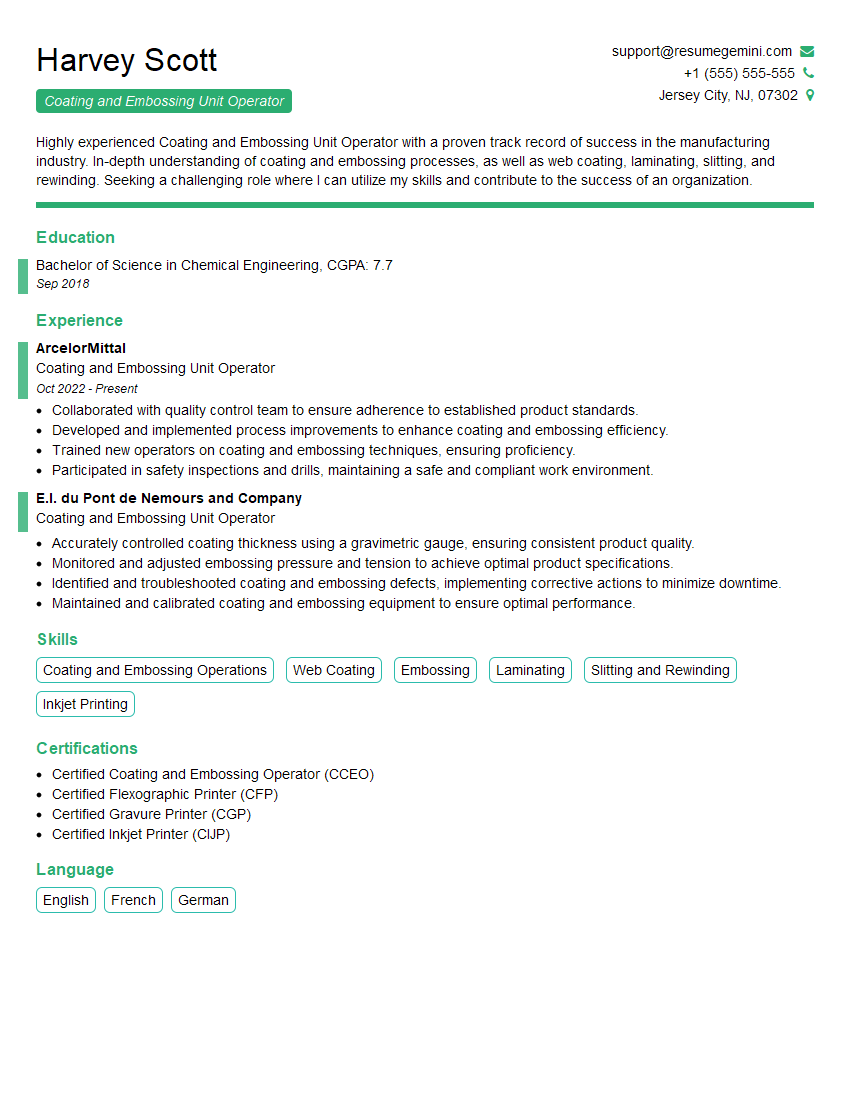

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Coating and Embossing Unit Operator

1. What is the role of a coater in a coating and embossing unit?

As a coater, I am responsible for applying a coating to the surface of various materials, such as paper, plastic, or metal. The coating provides a protective layer and improves the material’s appearance, durability, or other properties.

2. Explain the different types of coating methods used in the coating and embossing process.

Gravure Coating

- In gravure coating, the coating is transferred to the substrate from an engraved roller.

- This method is ideal for high-volume applications and can produce high-quality results.

Flexographic Coating

- Flexographic coating uses a flexible printing plate to transfer the coating to the substrate.

- It is a versatile method suitable for a wide range of materials.

Offset Coating

- Offset coating involves transferring the coating to an intermediate roller before it is applied to the substrate.

- This method provides precise coating control and is often used for delicate materials.

Reverse Roll Coating

- In reverse roll coating, the substrate passes between two rollers, one of which is coated with the coating material.

- This method is suitable for high-viscosity coatings and can achieve precise coating thickness.

3. What are the factors that affect the quality of the coating?

- Coating viscosity

- Substrate surface tension

- Coating application method

- Environmental conditions

4. How do you ensure the coating meets the specified requirements?

- Monitor coating thickness using appropriate measuring instruments.

- Inspect the coating for defects, such as bubbles, streaks, or pinholes.

- Conduct adhesion tests to ensure the coating adheres properly to the substrate.

- Perform regular calibration and maintenance of coating equipment.

5. What are the safety precautions that need to be followed when working with coating materials?

- Wear appropriate personal protective equipment (PPE), such as gloves, respirators, and eye protection.

- Handle coating materials with care, as they may be flammable or toxic.

- Ensure proper ventilation in the work area.

- Follow established safety protocols for handling and disposing of coating materials.

6. Describe the process of embossing and its role in the coating and embossing unit.

Embossing is a process where a pattern is impressed into the coated surface, creating a raised or textured effect. It enhances the aesthetic appeal of the material and can also provide additional functionality, such as increased grip or slip resistance.

7. What are the different types of embossing techniques?

Engraved Embossing

- Uses an engraved roller to press the pattern into the material.

- Produces high-quality results with precise details.

Thermo Embossing

- Applies heat and pressure to the coated surface, causing it to deform.

- Suitable for materials that are heat-sensitive.

Chemical Embossing

- Uses chemical reactions to create the embossed pattern.

- Provides a durable and resistant finish.

8. How do you maintain and troubleshoot the coating and embossing equipment?

- Regularly clean and inspect all equipment components.

- Calibrate coating and embossing settings to ensure accuracy.

- Troubleshoot common issues, such as coating defects, uneven embossing, or equipment malfunctions.

9. What quality control measures are in place to ensure the finished products meet customer specifications?

- Establish clear product specifications.

- Conduct regular inspections throughout the production process.

- Use measuring and testing equipment to verify product quality.

- Document quality control results for traceability and continuous improvement.

10. How do you stay updated with new developments in the coating and embossing industry?

- Attend industry conferences and exhibitions.

- Read trade publications and technical journals.

- Network with professionals in the field.

- Participate in training and certification programs.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Coating and Embossing Unit Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Coating and Embossing Unit Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Coating and Embossing Unit Operators play a crucial role in the manufacturing industry by ensuring the efficient operation of coating and embossing machines. Their responsibilities encompass a wide range of tasks related to the application of coatings and embossing designs onto various materials.

1. Machine Operation and Maintenance

Operate and monitor coating and embossing machines, ensuring optimal performance and quality output.

- Set up and adjust machine settings based on production specifications.

- Monitor machine parameters, identify potential issues, and perform routine maintenance to prevent breakdowns.

2. Coating Application

Apply coatings to materials using various techniques, including roller coating, spray coating, or dipping.

- Select and prepare appropriate coating materials based on product requirements.

- Control coating thickness and uniformity to meet customer specifications.

3. Embossing Operation

Emboss designs into materials using heated rollers or dies.

- Set up and operate embossing machines to create intricate patterns on various surfaces.

- Inspect embossed products to ensure design accuracy and quality.

4. Quality Control

Inspect and test coated and embossed products to ensure they meet quality standards.

- Conduct visual and functional inspections to identify defects or non-conformances.

- Perform quality control tests, such as adhesion tests, to validate product performance.

5. Production Support

Assist in material handling, equipment cleaning, and other production-related tasks as required.

- Load and unload materials from coating and embossing machines.

- Clean and maintain work areas to ensure a safe and efficient production environment.

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of making a positive impression and securing the position of Coating and Embossing Unit Operator. Here are some tips and hacks to help you ace the interview:

1. Research the Company and Position

Gather information about the company’s products, services, and industry reputation. Review the job description thoroughly to understand the specific requirements and responsibilities of the position.

- Visit the company’s website and social media pages.

- Read industry news and articles to stay updated on the latest trends and technologies.

2. Practice Your Answers

Anticipate common interview questions and prepare your answers in advance. Practice speaking clearly and confidently, emphasizing your skills, experience, and qualifications.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

- Quantify your accomplishments whenever possible using specific metrics or outcomes.

3. Highlight Relevant Skills and Experience

Tailor your resume and interview responses to showcase your relevant skills and experience. Emphasize your proficiency in coating and embossing techniques, machine operation, and quality control procedures.

- Provide examples of projects or tasks where you successfully applied coating and embossing knowledge.

- Discuss any certifications or training you have received in these areas.

4. Demonstrate Safety Awareness

Coating and embossing operations involve potential hazards. Highlight your understanding of safety protocols and procedures, and emphasize your commitment to working safely and efficiently.

- Explain your experience in following safety guidelines and wearing appropriate personal protective equipment (PPE).

- Discuss any safety-related initiatives or improvements you have implemented in previous roles.

5. Ask Insightful Questions

Asking thoughtful questions at the end of the interview demonstrates your interest in the position and the company. Prepare questions about the company’s growth plans, industry trends, or opportunities for professional development.

- Avoid asking questions about salary or benefits at the initial interview.

- Show enthusiasm and ask questions that indicate your eagerness to learn and contribute.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Coating and Embossing Unit Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.