Are you gearing up for an interview for a Coating Line Worker position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Coating Line Worker and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

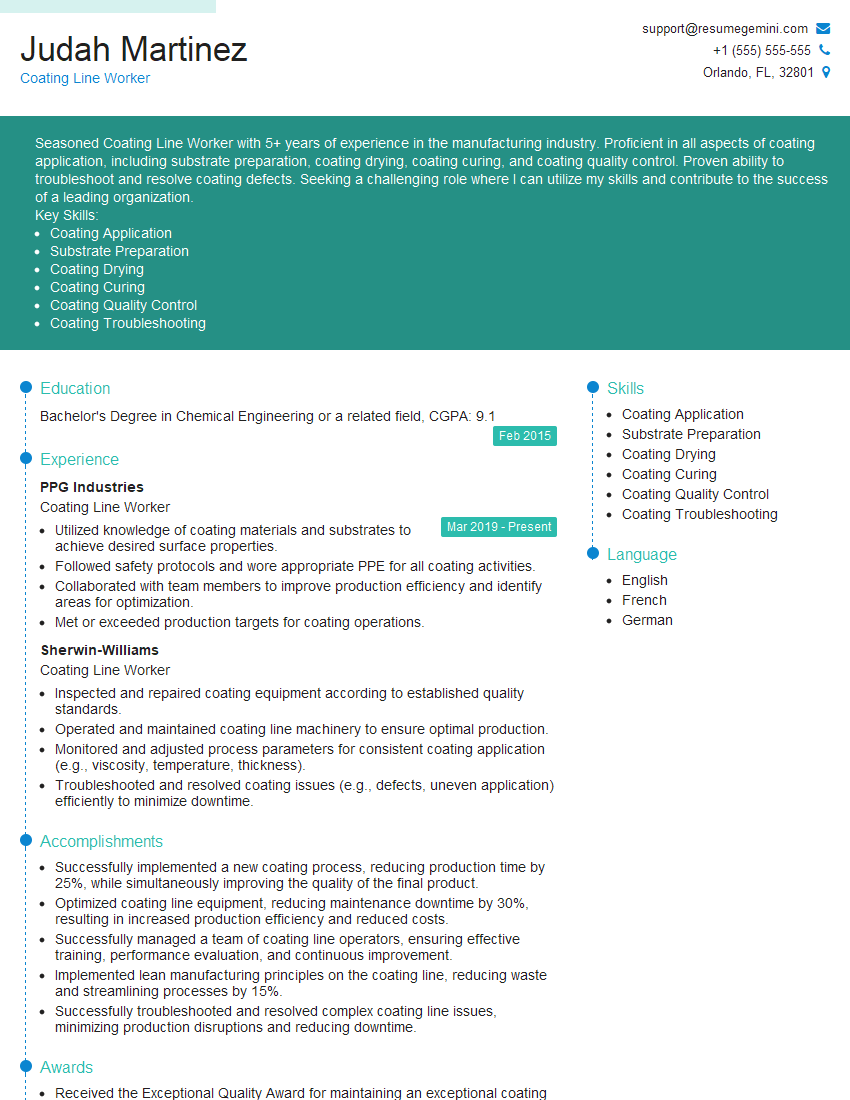

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Coating Line Worker

1. What are the different types of coating lines?

- Vertical coating lines – Used to coat large, flat surfaces, such as metal panels or glass. The workpiece is held vertically in the coating chamber and the coating is applied from above.

- Horizontal coating lines – Used to coat small, flat surfaces, such as metal sheets or plastic film. The workpiece is held horizontally in the coating chamber and the coating is applied from below.

- Coil coating lines – Used to coat metal coils for use in construction and manufacturing. The coil is fed into the coating chamber and the coating is applied while the coil is moving through the chamber.

2. What are the different types of coatings that can be applied using a coating line?

- Paint – A liquid or powder coating that is applied to a surface to protect it from corrosion or wear or to give it a desired appearance.

- Powder – A dry coating that is applied to a surface and then melted to form a continuous film.

- Enamel – A glass-like coating that is applied to a surface to protect it from heat or chemicals.

- Plating – A metal coating that is applied to a surface to improve its conductivity, corrosion resistance, or wear resistance.

3. What are the key factors that affect the quality of a coating?

- Surface preparation – The surface of the workpiece must be properly cleaned and prepared before the coating is applied.

- Coating application – The coating must be applied evenly and at the correct thickness.

- Coating curing – The coating must be cured properly to achieve the desired properties.

- Environmental conditions – The temperature, humidity, and other environmental conditions can affect the quality of the coating.

4. What are the common problems that can occur during the coating process?

- Blisters – Bubbles that form in the coating due to trapped air or moisture.

- Cracks – Breaks in the coating due to stress or impact.

- Peeling – The coating separates from the surface of the workpiece.

- Discoloration – The coating changes color due to exposure to light, heat, or chemicals.

5. How do you troubleshoot coating problems?

- Identify the problem – Determine the type of problem and the possible causes.

- Investigate the cause – Gather data and perform tests to determine the root cause of the problem.

- Develop a solution – Implement a solution to correct the problem and prevent it from recurring.

- Monitor the solution – Track the results of the solution to ensure that the problem has been resolved.

6. What are the safety procedures that must be followed when working on a coating line?

- Wear appropriate PPE – Wear gloves, safety glasses, and a respirator when working with coating materials.

- Handle chemicals safely – Follow all safety instructions when handling chemicals and dispose of them properly.

- Operate equipment safely – Be familiar with the operation of all coating equipment and follow all safety procedures.

- Maintain a clean work area – Keep the coating line clean and free of debris to prevent accidents.

7. What are the maintenance procedures that must be performed on a coating line?

- Regular cleaning – Clean the coating line regularly to remove dirt, debris, and coating residue.

- Lubrication – Lubricate all moving parts of the coating line to prevent wear and tear.

- Inspection – Inspect the coating line regularly for any signs of damage or wear and tear.

- Calibration – Calibrate all measuring and control devices on the coating line to ensure accuracy.

8. What are the quality control procedures that must be followed when operating a coating line?

- Monitor coating thickness – Monitor the thickness of the coating to ensure that it meets specifications.

- Inspect coating appearance – Inspect the coating for any defects, such as blisters, cracks, or peeling.

- Test coating performance – Test the coating to ensure that it meets the desired performance requirements.

- Document quality control results – Document all quality control results to track the performance of the coating line.

9. What are the different types of equipment that are used on a coating line?

- Coating applicator – The equipment that applies the coating to the workpiece.

- Coating oven – The equipment that cures the coating.

- Cooling system – The equipment that cools the workpiece after it has been coated.

- Conveyor system – The equipment that transports the workpiece through the coating line.

- Control system – The equipment that monitors and controls the coating process.

10. What are the challenges of working on a coating line?

- Working with hazardous materials – Coating materials can be hazardous to health, so it is important to follow all safety procedures.

- Maintaining a clean work environment – The coating line must be kept clean to prevent contamination of the coating.

- Working under time pressure – Coating lines often operate on a tight schedule, so it is important to be able to work quickly and efficiently.

- Troubleshooting coating problems – Coating problems can be complex and difficult to troubleshoot, so it is important to have a good understanding of the coating process.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Coating Line Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Coating Line Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Coating Line Workers play a crucial role in the manufacturing process, ensuring that products meet the required standards for quality and safety. Their responsibilities encompass a wide range of tasks, including:

1. Operating and Maintaining Coating Line Equipment

Operate coating line machinery, such as conveyors, ovens, mixers, and coating applicators, to apply coatings to various materials.

- Monitor equipment performance and make necessary adjustments to ensure optimal coating quality.

- Troubleshoot and resolve equipment malfunctions and breakdowns.

2. Preparing and Mixing Coating Materials

Prepare and mix coating materials according to specified formulations and procedures.

- Calculate and measure ingredients accurately to achieve the desired coating properties.

- Operate mixing equipment to create homogeneous and consistent coating mixtures.

3. Applying Coatings and Inspecting Products

Apply coatings to materials using various methods, such as dipping, spraying, or rolling.

- Monitor the coating process to ensure uniform coverage and thickness.

- Inspect coated products for defects, imperfections, or non-conformities.

4. Maintaining a Safe and Clean Work Environment

Follow safety protocols and wear appropriate protective gear to minimize risks.

- Clean and maintain work areas, equipment, and tools to prevent contamination.

- Dispose of hazardous materials and waste in accordance with environmental regulations.

Interview Tips

Preparing for a Coating Line Worker interview requires research, practice, and a thorough understanding of the role. Here are some tips to help you ace the interview:

1. Research the Company and the Role

Before the interview, take the time to research the company’s industry, products, and culture. Also, review the job description carefully to identify the specific skills and qualifications required.

2. Prepare for Common Interview Questions

Practice answering common interview questions related to your experience, skills, and the coating industry. Consider using the STAR method (Situation, Task, Action, Result) to provide concise and effective answers.

3. Highlight Relevant Experience and Skills

Emphasize your experience in operating coating line equipment, preparing and mixing coating materials, and inspecting coated products. Showcase your problem-solving abilities, attention to detail, and commitment to safety.

4. Demonstrate Enthusiasm and Motivation

Convey your passion for the coating industry and your eagerness to learn and contribute. Highlight your interest in the company’s products and mission, and explain how your skills align with their goals.

5. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview shows your engagement and interest in the role. Prepare questions about the company’s growth plans, the challenges faced by the department, or the opportunities for professional development.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Coating Line Worker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!