Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Cocoa Room Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

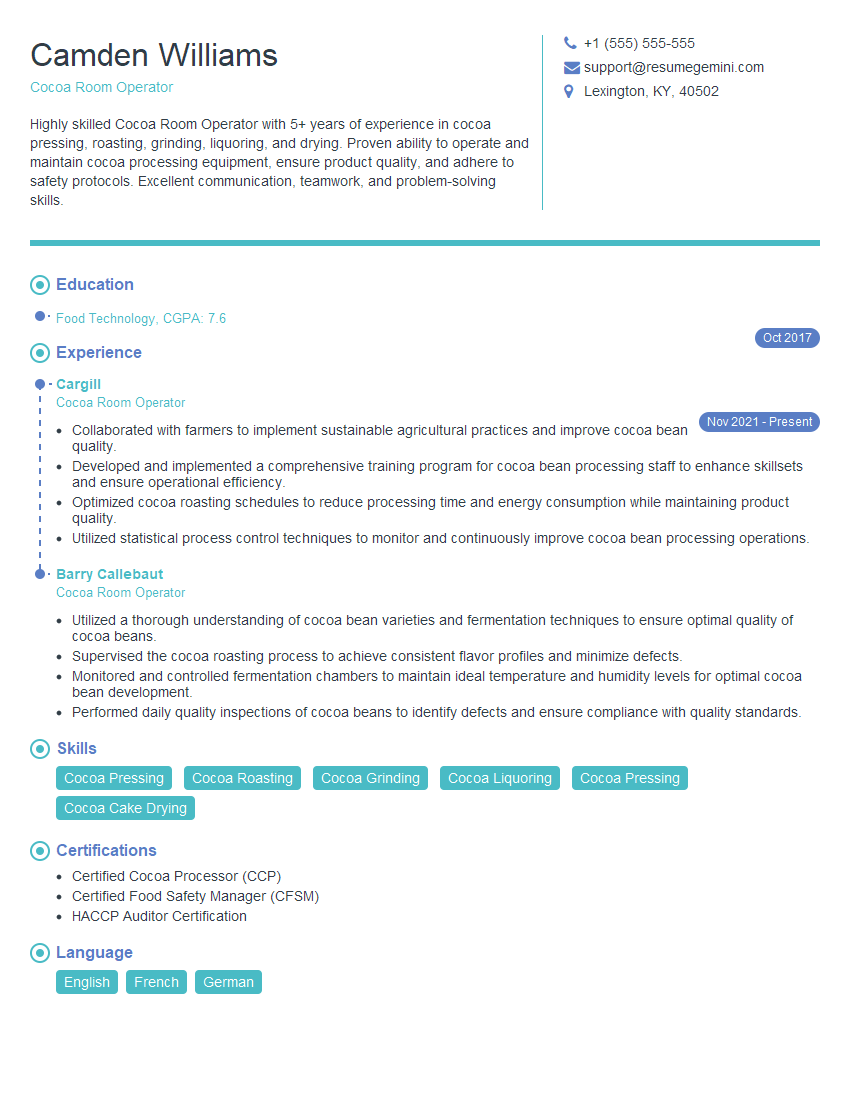

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cocoa Room Operator

1. What are the main responsibilities of a Cocoa Room Operator?

The primary responsibilities of a Cocoa Room Operator include:

- Monitoring and controlling the cocoa processing equipment

- Maintaining the cleanliness and sanitation of the cocoa processing area

- Ensuring the quality of the cocoa products

- Following safety procedures and regulations

2. What are the different types of cocoa processing equipment and what are their functions?

Batching equipment

- Weighs and mixes ingredients to create a uniform blend

Grinding equipment

- Breaks down cocoa beans into smaller particles to release their flavor and aroma

Mixing equipment

- Blends cocoa particles with other ingredients, such as sugar and milk powder, to create a smooth and consistent product

Liquefying equipment

- Converts cocoa particles into a liquid form

Drying equipment

- Removes moisture from cocoa liquor to create cocoa powder

3. What are the critical quality control parameters in cocoa processing and how do you monitor them?

Critical quality control parameters in cocoa processing include:

- Moisture content

- Fat content

- Acidity

- Color

- Flavor

These parameters are monitored through regular testing using various analytical techniques, such as:

- Moisture analyzers

- Fat extraction methods

- pH meters

- Colorimeters

- Sensory evaluation

4. What are the common safety hazards in a cocoa processing plant and what measures can be taken to mitigate them?

Common safety hazards in a cocoa processing plant include:

- Slips and falls

- Cuts and lacerations

- Fire and explosions

- Exposure to chemicals

- Repetitive motion injuries

Measures to mitigate these hazards include:

- Wearing appropriate safety gear

- Following proper operating procedures

- Maintaining a clean and organized work environment

- Using proper lockout/tagout procedures

- Providing training on safety hazards and prevention measures

5. What are the maintenance procedures for cocoa processing equipment?

Maintenance procedures for cocoa processing equipment include:

- Regular cleaning and inspection

- Lubrication of moving parts

- Adjustment of equipment settings

- Replacement of worn or damaged parts

- Monitoring and calibration of sensors and instruments

6. What are the different types of cocoa products and what are their applications?

Different types of cocoa products include:

- Cocoa beans: Raw and unprocessed cocoa beans

- Cocoa liquor: A thick, liquid form of cocoa

- Cocoa powder: A dry, powdered form of cocoa

- Chocolate: A sweet food made from cocoa solids, sugar, and other ingredients

Applications of cocoa products include:

- Chocolate bars and confectionery

- Baked goods

- Beverages

- Cosmetics

- Pharmaceuticals

7. What is the role of fermentation in cocoa processing?

Fermentation is a crucial step in cocoa processing that enhances the flavor, aroma, and color of cocoa beans. During fermentation, microorganisms break down the pulp surrounding the cocoa beans, releasing enzymes that convert the precursors of flavor and aroma compounds into their final forms.

8. Describe the process of conching in chocolate making.

Conching is a mechanical process used in chocolate making to refine the texture and flavor of chocolate. It involves grinding the chocolate mass under heat for several hours, which helps to break down particles, reduce bitterness, and develop a smooth, velvety texture.

9. What are the different methods of tempering chocolate and what is their purpose?

Tempering is a process used to stabilize the crystal structure of chocolate, improving its texture, appearance, and shelf life. Different tempering methods include:

Tabling

- Pour molten chocolate onto a marble slab and spread it out

- Work the chocolate with a scraper until it reaches the desired temperature

Seeding

- Add small pieces of tempered chocolate to melted chocolate

- Stir until the melted chocolate reaches the desired temperature

Machine tempering

- Use a machine that controls the temperature and agitation of the chocolate

- This method is more efficient and consistent than manual tempering

10. What are the key factors that affect the quality of cocoa products?

- Quality of cocoa beans

- Fermentation process

- Roasting and grinding

- Conching and tempering

- Storage and handling

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cocoa Room Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cocoa Room Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Cocoa Room Operators are responsible for the smooth and efficient operation of a cocoa processing room. They ensure that all equipment is running properly, that cocoa beans are processed according to specifications, and that the work environment is safe and sanitary.

1. Operate and maintain cocoa processing equipment

Cocoa Room Operators are responsible for operating and maintaining all of the equipment in the cocoa processing room. This includes grinders, roasters, winnowers, and presses. They must be able to troubleshoot and repair any problems that arise with the equipment.

- Operate grinders to break down cocoa beans into smaller pieces.

- Roast cocoa beans to develop their flavor and aroma.

- Winnow roasted cocoa beans to remove the husks.

- Press cocoa beans to extract cocoa liquor.

2. Monitor the cocoa processing process

Cocoa Room Operators must monitor the cocoa processing process to ensure that it is running smoothly and that the cocoa beans are being processed according to specifications. They must be able to identify any problems that arise and take corrective action.

- Monitor the temperature and humidity of the cocoa processing room.

- Check the quality of the cocoa beans and cocoa liquor.

- Adjust the processing equipment to ensure that the cocoa beans are processed according to specifications.

- Troubleshoot and repair any problems that arise with the processing equipment.

3. Maintain a safe and sanitary work environment

Cocoa Room Operators are responsible for maintaining a safe and sanitary work environment. They must clean and disinfect the equipment regularly and ensure that all employees are following safety procedures.

- Clean and disinfect the cocoa processing equipment.

- Ensure that all employees are wearing appropriate safety gear.

- Follow all safety procedures.

- Report any safety hazards to management.

4. Other duties

In addition to the above duties, Cocoa Room Operators may also be responsible for:

- Loading and unloading cocoa beans.

- Packaging and storing cocoa liquor.

- Assisting with other tasks as needed.

Interview Tips

Preparing for a Cocoa Room Operator interview can be a daunting task, but by following these tips, you can increase your chances of success.

1. Research the company and the position

Before you go into your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and values, and it will also help you prepare for the specific questions that you may be asked.

- Visit the company’s website.

- Read articles about the company in the news.

- Talk to people who work for the company.

- Review the job description carefully.

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and clearly.

- Write out your answers to common interview questions.

- Practice your answers out loud.

- Time yourself to make sure that your answers are concise.

3. Be prepared to talk about your experience

The interviewer will want to know about your experience and qualifications. Be prepared to talk about your previous jobs, your skills, and your education. You should also be able to provide examples of your work.

- Create a resume that highlights your relevant experience and skills.

- Prepare a portfolio of your work.

- Be able to talk about your experience in detail.

4. Dress professionally and arrive on time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This will show the interviewer that you are serious about the position and that you respect their time.

- Choose an outfit that is clean, pressed, and appropriate for a business setting.

- Arrive for your interview on time.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Cocoa Room Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!