Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Cogeneration Operator (Supervisor) interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Cogeneration Operator (Supervisor) so you can tailor your answers to impress potential employers.

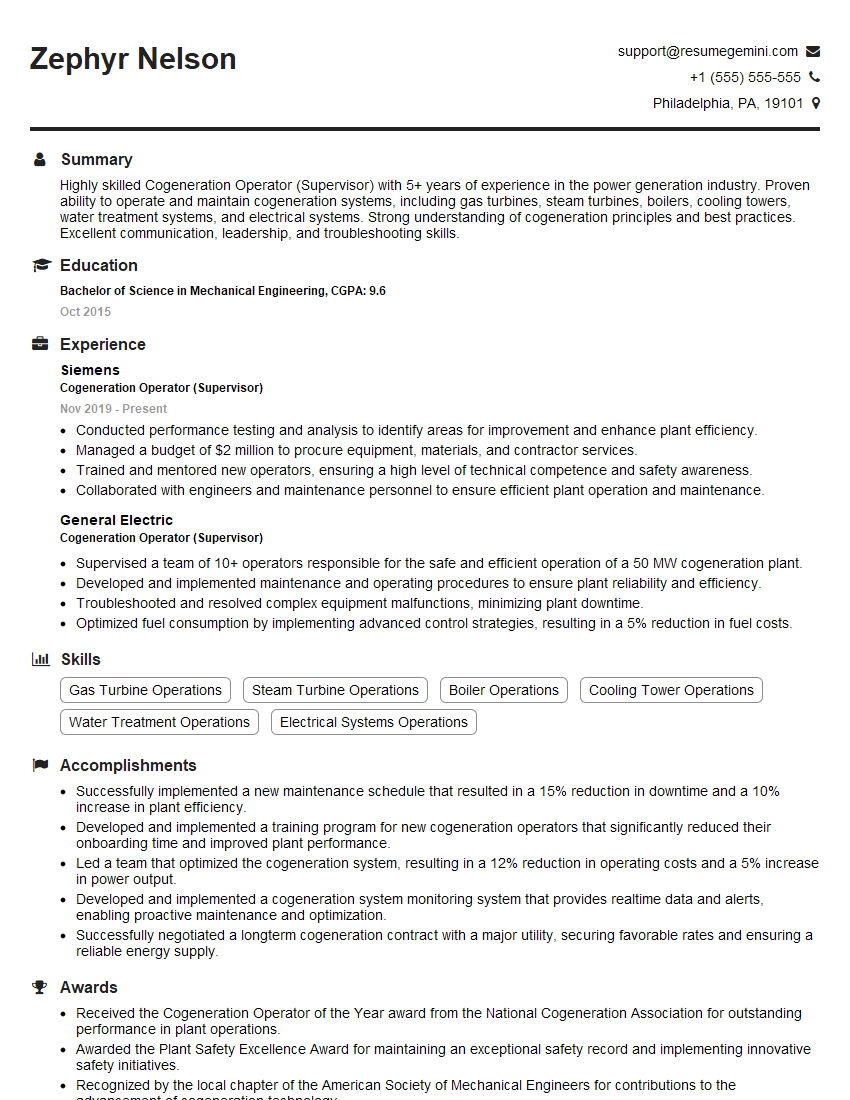

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cogeneration Operator (Supervisor)

1. What are the key performance indicators (KPIs) you would use to measure the performance of a cogeneration plant?

- Thermal efficiency: The ratio of useful heat output to the total fuel input.

- Electrical efficiency: The ratio of electrical output to the total fuel input.

- Overall efficiency: The ratio of the combined heat and electrical output to the total fuel input.

- Fuel consumption: The amount of fuel used per unit of time or output.

- Emissions: The amount of pollutants released into the atmosphere per unit of time or output.

- Availability: The percentage of time that the plant is available to operate.

- Reliability: The percentage of time that the plant is operating without unplanned outages.

- Maintainability: The ease with which the plant can be maintained and repaired.

2. Describe the main components of a cogeneration system and their functions.

Engine or turbine

- Converts fuel into mechanical energy, which is then used to generate electricity.

- The exhaust heat from the engine or turbine is used to generate steam or hot water.

Heat recovery system

- Captures the exhaust heat from the engine or turbine.

- Uses the heat to generate steam or hot water, which is then used for heating or cooling purposes.

Electrical generator

- Converts mechanical energy from the engine or turbine into electrical energy.

- The electrical energy is then sent to the grid or used on-site.

3. What are the advantages of cogeneration over conventional power generation?

- Increased efficiency: Cogeneration can achieve overall efficiencies of up to 90%, compared to around 50% for conventional power plants.

- Reduced emissions: Cogeneration can reduce greenhouse gas emissions by up to 50% compared to conventional power plants.

- Lower operating costs: Cogeneration can reduce operating costs by up to 20% compared to conventional power plants.

- Improved reliability: Cogeneration can improve reliability by providing backup power during outages.

- Reduced environmental impact: Cogeneration can reduce the environmental impact of power generation by reducing emissions and conserving natural resources.

4. What are the challenges associated with operating a cogeneration plant?

- Fuel availability: Cogeneration plants are typically reliant on natural gas or other fossil fuels, which can be subject to price fluctuations and supply disruptions.

- Emissions control: Cogeneration plants must meet strict emissions regulations, which can require the installation of expensive emissions control equipment.

- Permitting: Cogeneration plants require permits from a variety of regulatory agencies, which can be a lengthy and expensive process.

- Maintenance: Cogeneration plants require regular maintenance, which can be costly and time-consuming.

- Operation: Cogeneration plants must be operated carefully to ensure efficient and reliable operation.

5. How would you optimize the performance of a cogeneration plant?

- Monitor key performance indicators (KPIs) and make adjustments as necessary.

- Perform regular maintenance and repairs to keep the plant operating at peak efficiency.

- Train operators on best practices for operating the plant.

- Invest in new technologies to improve the efficiency and reliability of the plant.

- Work with customers to optimize the use of the plant’s heat and power output.

6. What are the safety hazards associated with operating a cogeneration plant?

- Electrical hazards: Cogeneration plants contain high-voltage electrical equipment, which can pose a risk of electrical shock or arc flash.

- Mechanical hazards: Cogeneration plants contain moving machinery, which can pose a risk of injury or death.

- Chemical hazards: Cogeneration plants use a variety of chemicals, which can pose a risk of chemical burns or poisoning.

- Fire hazards: Cogeneration plants use flammable fuels, which can pose a risk of fire or explosion.

- Noise hazards: Cogeneration plants can generate loud noise, which can pose a risk of hearing loss.

7. How would you respond to an emergency at a cogeneration plant?

- Assess the situation and identify the source of the emergency.

- Activate the emergency response plan.

- Evacuate the plant if necessary.

- Secure the plant and stop the flow of fuel and electricity.

- Notify the appropriate authorities and emergency responders.

- Investigate the cause of the emergency and take steps to prevent future emergencies.

8. What is your experience with managing a team of operators?

- Supervised a team of 10 operators at a large cogeneration plant for 5 years.

- Developed and implemented training programs to improve operator performance.

- Created and maintained a safe and productive work environment.

- Resolved conflicts and disciplinary issues in a fair and impartial manner.

- Coordinated with other departments to ensure the smooth operation of the plant.

9. What are your strengths and weaknesses as a Cogeneration Operator (Supervisor)?

Strengths

- Strong technical understanding of cogeneration systems.

- Proven ability to operate and maintain cogeneration plants safely and efficiently.

- Excellent communication and interpersonal skills.

- Strong leadership and management skills.

- Proven ability to work independently and as part of a team.

Weaknesses

- Limited experience with some newer cogeneration technologies.

- Can be a bit impatient at times.

- Sometimes have difficulty delegating tasks.

10. What are your career goals?

- To continue to advance my career in the cogeneration industry.

- To become a Plant Manager or Director of Operations.

- To make a significant contribution to the field of cogeneration.

- To help reduce greenhouse gas emissions and promote the use of renewable energy.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cogeneration Operator (Supervisor).

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cogeneration Operator (Supervisor)‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Cogeneration Operators (Supervisors) play a critical role in ensuring the efficient and safe operation of cogeneration facilities that produce both electricity and thermal energy. Their responsibilities encompass managing the operation of cogeneration systems, supervising personnel, and maintaining the facility to meet regulatory and safety standards.

1. Cogeneration System Operation and Maintenance

Supervise and operate cogeneration systems, including gas turbines, steam turbines, boilers, and heat recovery systems.

- Monitor and adjust system parameters to optimize performance and efficiency.

- Troubleshoot and resolve system malfunctions to minimize downtime and maintain reliability.

2. Personnel Management

Supervise a team of operators and technicians, providing guidance and training on safe and efficient operating procedures.

- Assign tasks, monitor performance, and provide feedback to improve operational efficiency.

- Ensure compliance with safety regulations and standards.

3. Facility Maintenance and Safety

Oversee the maintenance and upkeep of the cogeneration facility, including equipment, buildings, and grounds.

- Coordinate inspections, repairs, and preventive maintenance to ensure optimal system functioning.

- Implement and enforce safety protocols, including emergency response procedures and hazardous material handling.

4. Compliance and Reporting

Monitor and ensure compliance with environmental regulations, industry standards, and company policies.

- Maintain accurate records of system performance, emissions, and other operational data.

- Collaborate with regulatory agencies and external stakeholders on compliance matters.

Interview Tips

Preparing thoroughly for an interview is crucial for showcasing your qualifications and maximizing your chances of success. Here are some tips to help you ace your interview as a Cogeneration Operator (Supervisor):

1. Research the Company and Industry

Familiarize yourself with the company’s profile, core operations, and cogeneration industry trends. This knowledge will demonstrate your genuine interest and understanding.

2. Highlight Relevant Experience and Skills

Focus on highlighting your experience operating and maintaining cogeneration systems, supervising teams, and ensuring compliance. Quantify your accomplishments whenever possible to provide tangible evidence of your impact.

3. Emphasize Safety and Regulatory Awareness

Emphasize your strong commitment to safety, compliance, and environmental stewardship. Share examples of how you have implemented and enforced safety protocols or ensured compliance with regulations.

4. Prepare for Technical Questions

Be prepared to answer technical questions related to cogeneration system operations, maintenance, troubleshooting, and regulatory compliance. Review key concepts and familiarize yourself with industry standards.

5. Practice STAR Method

When answering behavioral interview questions, use the STAR method (Situation, Task, Action, Result) to provide specific and structured responses. This technique allows you to highlight your skills and accomplishments clearly.

6. Demonstrate Leadership and Teamwork

Highlight your leadership abilities and experience working effectively in a team environment. Provide examples of how you have motivated and guided your team to achieve operational goals.

7. Ask Informed Questions

At the end of the interview, ask thoughtful questions about the company, the role, and the industry. This shows your engagement and interest in the opportunity.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Cogeneration Operator (Supervisor), it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Cogeneration Operator (Supervisor) positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.