Feeling lost in a sea of interview questions? Landed that dream interview for Coil Builder but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Coil Builder interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

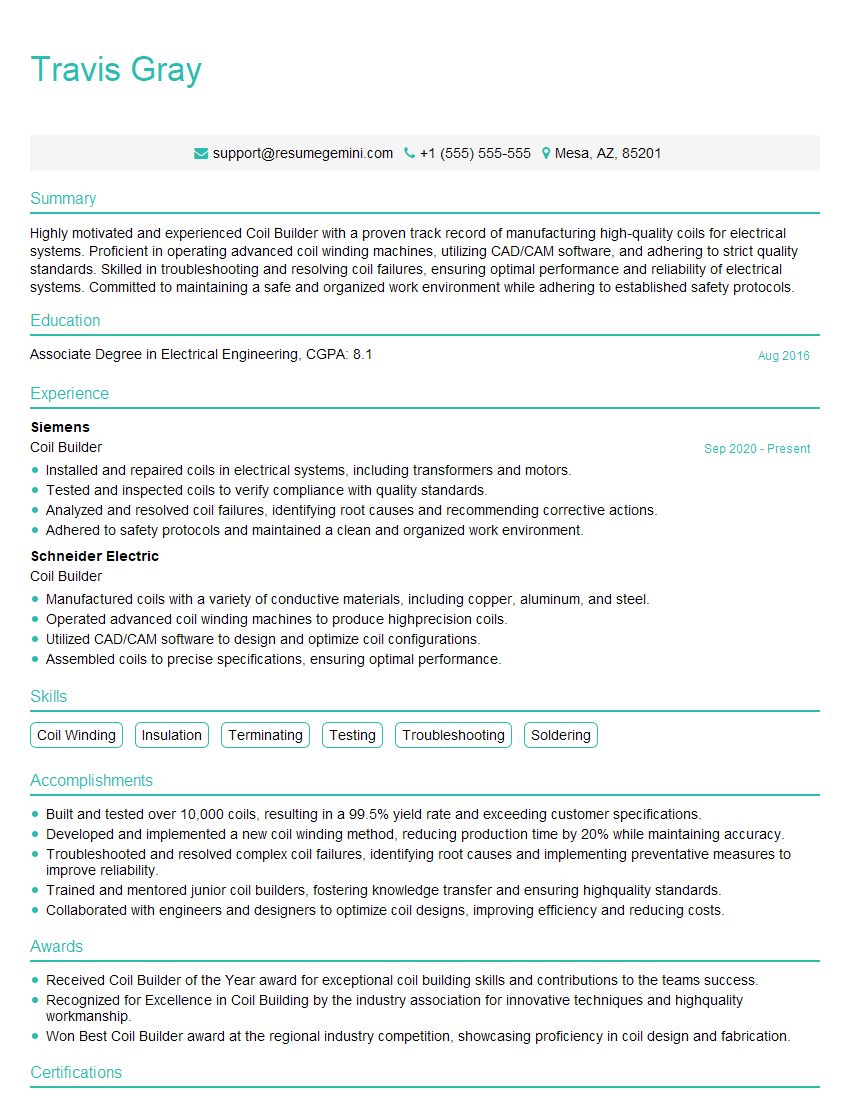

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Coil Builder

1. Explain the different types of coil winding machines and their applications?

- Shuttle winding machines: These machines are used to wind coils on cylindrical or rectangular formers. They can be used to wind a variety of coil types, including single-layer, multi-layer, and cross-wound coils.

- Helical winding machines: These machines are used to wind coils on helical formers. They can be used to wind a variety of coil types, including single-layer and multi-layer coils.

- Toroidal winding machines: These machines are used to wind coils on toroidal formers. They can be used to wind a variety of coil types, including single-layer and multi-layer coils.

- Formless winding machines: These machines are used to wind coils without using a former. They can be used to wind a variety of coil types, including single-layer, multi-layer, and cross-wound coils.

2. What are the key factors to consider when selecting a coil winding machine?

Coil type

- The type of coil that you need to wind will determine the type of coil winding machine that you need to use.

Coil size

- The size of the coil that you need to wind will determine the size of the coil winding machine that you need to use.

Coil winding speed

- The speed at which you need to wind the coil will determine the speed of the coil winding machine that you need to use.

Coil winding accuracy

- The accuracy at which you need to wind the coil will determine the accuracy of the coil winding machine that you need to use.

3. What are the different types of coil winding materials and their properties?

- Copper: Copper is a good conductor of electricity and heat, and it is relatively easy to solder. However, copper is also relatively expensive.

- Aluminium: Aluminium is a good conductor of electricity and heat, and it is less expensive than copper. However, aluminium is also more difficult to solder.

- Litz wire: Litz wire is a type of wire that is made up of multiple strands of smaller wire. Litz wire is used to reduce the skin effect, which is a phenomenon that causes the current density to be higher on the outside of a wire than on the inside. However, litz wire is also more expensive than solid wire.

4. What are the different types of coil winding defects and how can they be prevented?

- Shorted turns: Shorted turns occur when two or more turns of the coil are accidentally connected together. This can cause the coil to overheat and fail.

- Open turns: Open turns occur when a turn of the coil is broken. This can cause the coil to fail.

- Wrong winding direction: Wrong winding direction occurs when the coil is wound in the wrong direction. This can cause the coil to produce the wrong magnetic field.

- Uneven winding: Uneven winding occurs when the coil is wound unevenly. This can cause the coil to have a non-uniform magnetic field.

5. What are the different types of coil testing and how are they performed?

- DC resistance testing: DC resistance testing is used to measure the resistance of the coil. This test can be used to identify shorted turns and open turns.

- AC impedance testing: AC impedance testing is used to measure the impedance of the coil. This test can be used to identify shorted turns and open turns, as well as other defects.

- Hipot testing: Hipot testing is used to test the insulation of the coil. This test can be used to identify weak spots in the insulation.

6. What are the different safety precautions that should be taken when working with coil winding machines?

- Wear appropriate safety gear, including safety glasses, gloves, and a lab coat.

- Keep your work area clean and free of clutter.

- Do not operate coil winding machines while under the influence of alcohol or drugs.

- Follow all manufacturer instructions for the safe operation of coil winding machines.

7. Explain the principles of electromagnetic induction and how they apply to coil winding?

Electromagnetic induction is the process by which a changing magnetic field induces an electromotive force (EMF) in a conductor. When a coil is wound, the magnetic field created by the current flowing through the coil induces an EMF in the coil. This EMF is proportional to the number of turns in the coil, the current flowing through the coil, and the rate of change of the magnetic field.

8. What are the different types of magnetic materials and their properties?

- Soft magnetic materials: Soft magnetic materials are materials that can be easily magnetised and demagnetised. They are used in applications where the magnetic field needs to be changed frequently, such as in transformers and inductors.

- Hard magnetic materials: Hard magnetic materials are materials that are difficult to magnetise and demagnetise. They are used in applications where the magnetic field needs to be permanent, such as in magnets.

9. What are the different types of coil design software and how are they used?

- 2D coil design software: 2D coil design software is used to design coils in two dimensions. This software can be used to calculate the inductance, resistance, and other properties of the coil.

- 3D coil design software: 3D coil design software is used to design coils in three dimensions. This software can be used to calculate the inductance, resistance, and other properties of the coil, as well as to visualise the coil in three dimensions.

10. How do you stay up-to-date on the latest coil winding technologies?

- Read industry publications: There are a number of industry publications that cover the latest coil winding technologies. These publications can be found online or in print.

- Attend industry conferences: Industry conferences are a great way to learn about the latest coil winding technologies. These conferences are held all over the world, and they offer a variety of presentations and workshops on the latest coil winding technologies.

- Talk to other coil winding professionals: Talking to other coil winding professionals is a great way to learn about the latest coil winding technologies. These professionals can share their experiences and knowledge, and they can help you to troubleshoot any problems that you may be having.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Coil Builder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Coil Builder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Coil Builders play a crucial role in the manufacturing process and possess specialized skills essential for the smooth functioning of production lines. Here are the key job responsibilities they undertake:1. Coil Winding and Assembly

Coil Builders are responsible for winding electrical coils according to specified designs and parameters. They use specialized machinery to precisely wrap conductive wire around a magnetic core or former, ensuring the proper number of turns, spacing, and alignment.

2. Quality Control

Maintaining the quality of coils is paramount. Coil Builders conduct thorough inspections throughout the winding process to identify and rectify any irregularities or defects. They employ various testing methods, such as electrical resistance and inductance measurements, to ensure coils meet required specifications.

3. Production Management

To optimize production efficiency, Coil Builders monitor and manage the progress of coil winding operations. They track production schedules, identify bottlenecks, and implement measures to enhance productivity while maintaining quality standards.

4. Equipment Maintenance

Coil Builders perform routine maintenance and troubleshooting of coil winding machinery to ensure optimal performance. They conduct regular inspections, clean and lubricate components, and make necessary adjustments to maintain precision and accuracy.

Interview Tips

Preparation is key to acing an interview. Here are some valuable tips and hacks for Coil Builder candidates:

1. Research the Company and Industry

Thoroughly research the company you’re applying to and the industry it operates in. This knowledge will demonstrate your interest and eagerness to contribute to their team.

2. Highlight Your Skills and Experience

Emphasize your relevant skills and experience in coil winding and quality control. Quantify your accomplishments whenever possible to showcase your impact. For example, you could mention the number of coils you’ve wound or the percentage increase in production efficiency you achieved.

3. Prepare for Technical Questions

Expect technical questions related to coil winding techniques, quality control methods, and equipment maintenance. Review your knowledge and practice answering questions clearly and concisely. For instance, be prepared to explain how you ensure proper coil insulation or how you troubleshoot common winding defects.

4. Demonstrate Your Problem-Solving Abilities

Interviewers often ask situational questions to assess your problem-solving skills. Think through scenarios you’ve encountered in previous roles and prepare your responses. For example, how you handled a production delay or solved a quality issue with a complex coil design.

5. Practice Your Communication Skills

Excellent communication is crucial in any role. Practice articulating your thoughts effectively and confidently. Be prepared to discuss your work experience, technical expertise, and how you would contribute to the company.

6. Come Prepared with Questions

Asking thoughtful questions during the interview shows your engagement and interest in the position. Prepare questions about the company’s goals, the specific requirements of the role, and opportunities for professional development.

7. Dress Professionally and Arrive on Time

First impressions matter. Dress professionally and arrive at the interview venue on time to demonstrate your respect for the company and its time.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Coil Builder role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.