Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Coil Repair Technician position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

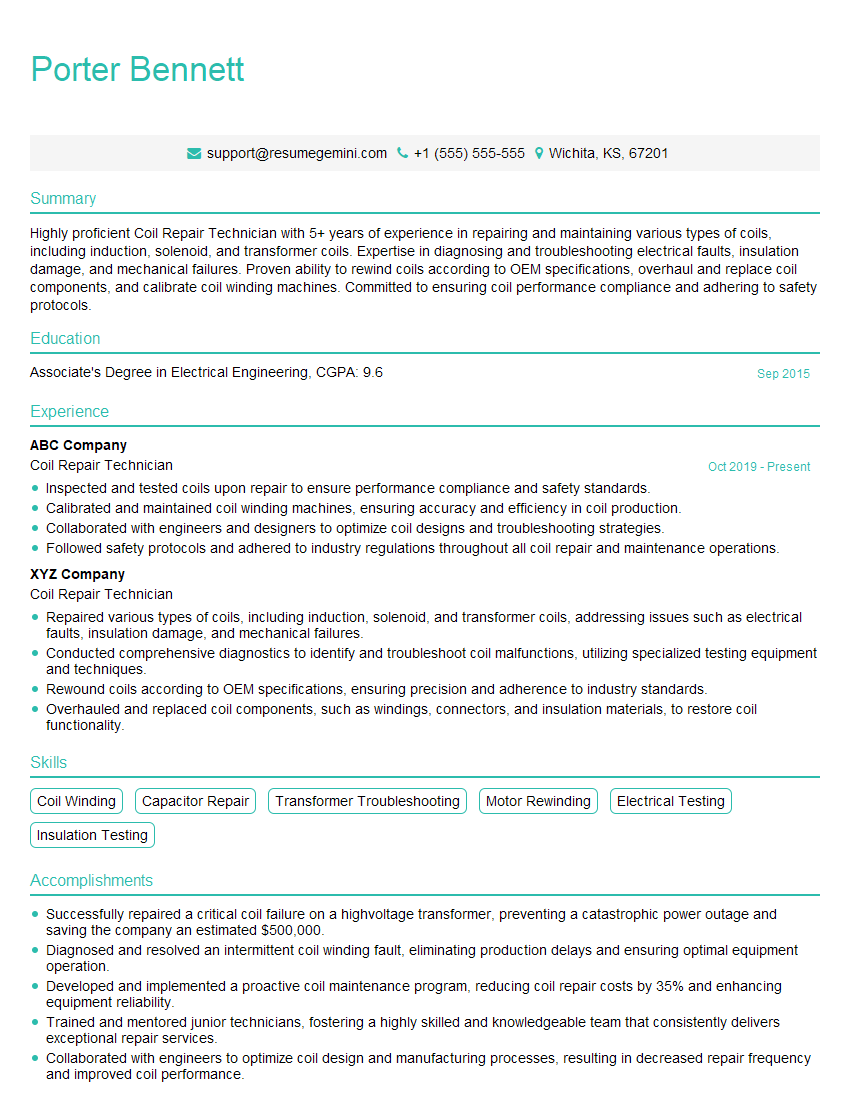

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Coil Repair Technician

1. Describe the process of testing a coil for continuity.

To test a coil for continuity, I would follow these steps:

- Set my multimeter to the continuity setting.

- Touch one probe to each terminal of the coil.

- If the coil is good, the multimeter will emit a beep or display a reading of 0 ohms.

- If the coil is open, the multimeter will not emit a beep or will display a reading of infinity.

2. How do you troubleshoot a coil that is not turning on?

Check the power supply

- Make sure that the coil is receiving power from the power supply.

- Check the wiring connections to the coil.

- Check the fuse or circuit breaker for the coil.

Check the coil itself

- Test the coil for continuity.

- Check the coil for shorts.

- Check the coil for opens.

Check the control circuit

- Check the wiring connections to the control circuit.

- Check the switches and relays in the control circuit.

- Check the timer in the control circuit.

3. What are the different types of coils and what are their applications?

There are many different types of coils, each with its own unique application. Some of the most common types of coils include:

- Inductors: Inductors are used to store energy in a magnetic field. They are typically used in electronic circuits to filter out unwanted frequencies.

- Transformers: Transformers are used to change the voltage or current of an electrical signal. They are typically used in power distribution systems and in electronic devices.

- Solenoids: Solenoids are used to convert electrical energy into mechanical energy. They are typically used in switches, valves, and other devices that require linear motion.

- Relays: Relays are used to control the flow of current in a circuit. They are typically used in electronic circuits to switch between different circuits or to protect the circuit from overload.

4. What are the safety precautions that should be taken when working with coils?

When working with coils, it is important to take the following safety precautions:

- Always wear safety glasses.

- Never touch a coil that is energized.

- Be aware of the magnetic field around a coil.

- Do not work on a coil that is hot.

- Always follow the manufacturer’s instructions when working with coils.

5. What is the difference between a coil and a transformer?

A coil is a passive electrical component that stores energy in a magnetic field. A transformer is a passive electrical component that transfers energy from one circuit to another through electromagnetic induction.

- Coils are used to store energy and to filter out unwanted frequencies.

- Transformers are used to change the voltage or current of an electrical signal.

6. What is the difference between a coil and a solenoid?

A coil is a passive electrical component that stores energy in a magnetic field. A solenoid is a type of coil that is used to convert electrical energy into mechanical energy.

- Coils are used to store energy and to filter out unwanted frequencies.

- Solenoids are used to convert electrical energy into mechanical energy.

7. What is the difference between a coil and a relay?

A coil is a passive electrical component that stores energy in a magnetic field. A relay is a type of coil that is used to control the flow of current in a circuit.

- Coils are used to store energy and to filter out unwanted frequencies.

- Relays are used to control the flow of current in a circuit.

8. What are the different types of materials that can be used to make coils?

The type of material used to make a coil depends on the application of the coil. Some of the most common materials used to make coils include:

- Copper: Copper is a good conductor of electricity and is often used to make coils that are used in electronic circuits.

- Aluminum: Aluminum is a lightweight and inexpensive material that is often used to make coils that are used in power distribution systems.

- Iron: Iron is a magnetic material that is often used to make coils that are used in transformers and solenoids.

9. What are the factors that affect the inductance of a coil?

The inductance of a coil is affected by the following factors:

- Number of turns: The more turns a coil has, the higher its inductance.

- Length of the coil: The longer a coil is, the higher its inductance.

- Diameter of the coil: The larger the diameter of a coil, the lower its inductance.

- Material of the core: The material of the core of a coil affects its inductance. Coils with iron cores have higher inductance than coils with air cores.

10. What are the applications of coils in the electrical industry?

Coils are used in a wide variety of applications in the electrical industry, including:

- Inductors: Inductors are used to store energy in a magnetic field. They are typically used in electronic circuits to filter out unwanted frequencies.

- Transformers: Transformers are used to change the voltage or current of an electrical signal. They are typically used in power distribution systems and in electronic devices.

- Solenoids: Solenoids are used to convert electrical energy into mechanical energy. They are typically used in switches, valves, and other devices that require linear motion.

- Relays: Relays are used to control the flow of current in a circuit. They are typically used in electronic circuits to switch between different circuits or to protect the circuit from overload.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Coil Repair Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Coil Repair Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Coil Repair Technician is responsible for repairing and maintaining a variety of coils, including solenoids, stators, and transformers. They may work in a variety of settings, such as manufacturing plants, repair shops, or utilities.

1. Coil Repair

Coil repair technicians are responsible for identifying and repairing a variety of coil defects, such as shorts, opens, and grounds. They may also need to replace damaged coils or windings.

- Repair or replace damaged coils or windings

- Identify and repair a variety of coil defects, such as shorts, opens, and grounds

2. Coil Testing

Coil repair technicians are responsible for testing coils to ensure that they meet specifications. They may use a variety of testing methods, such as resistance testing, insulation testing, and hipot testing.

- Test coils to ensure that they meet specifications

- Use a variety of testing methods, such as resistance testing, insulation testing, and hipot testing

3. Coil Installation

Coil repair technicians may also be responsible for installing coils in a variety of equipment, such as motors, generators, and transformers. They must ensure that the coils are installed correctly and that they meet all safety requirements.

- Install coils in a variety of equipment, such as motors, generators, and transformers

- Ensure that the coils are installed correctly and that they meet all safety requirements

4. Troubleshooting

Coil repair technicians are responsible for troubleshooting problems with coils. They may need to identify the source of the problem and then develop a solution. They must be able to work independently and as part of a team.

- Troubleshoot problems with coils

- Identify the source of the problem and then develop a solution

Interview Tips

Interviewing for a Coil Repair Technician position can be a daunting task. However, by preparing adequately and practicing your answers to common interview questions, you can increase your chances of success.

1. Research the Company and Position

Before your interview, take the time to research the company and the specific position you are applying for. This will help you understand the company’s culture and values, as well as the specific skills and experience they are looking for in a Coil Repair Technician. You can find information about the company on their website, social media pages, and Glassdoor.

- Read the company’s website

- Check the company’s social media pages

- Read reviews on Glassdoor

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked during an interview for a Coil Repair Technician position. It is important to practice your answers to these questions so that you can deliver them confidently and concisely. Some common interview questions include:

- Tell me about your experience in coil repair.

- What are your strengths and weaknesses as a Coil Repair Technician?

- Why are you interested in this position?

3. Be Prepared to Discuss Your Skills and Experience

During your interview, the interviewer will want to know about your skills and experience as a Coil Repair Technician. Be prepared to discuss your experience in repairing a variety of coils, as well as your knowledge of coil testing and installation. You should also be able to demonstrate your troubleshooting skills and your ability to work independently and as part of a team.

- Highlight your experience in repairing a variety of coils

- Discuss your knowledge of coil testing and installation

- Demonstrate your troubleshooting skills

- Emphasize your ability to work independently and as part of a team

4. Dress Professionally and Arrive on Time

It is important to dress professionally for your interview and to arrive on time. This will show the interviewer that you are serious about the position and that you respect their time.

- Dress professionally

- Arrive on time

5. Be Polite and Respectful

Be polite and respectful to the interviewer and to everyone else you meet during your interview. This will create a positive impression and make you more likely to be remembered.

- Be polite and respectful to the interviewer

- Be polite and respectful to everyone else you meet during your interview

6. Follow Up After the Interview

After your interview, be sure to follow up with the interviewer. This will show them that you are still interested in the position and that you appreciate their time.

- Send a thank-you note to the interviewer

- Follow up with the interviewer if you have not heard back within a week

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Coil Repair Technician interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!