Are you gearing up for an interview for a Coil Shaper position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Coil Shaper and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

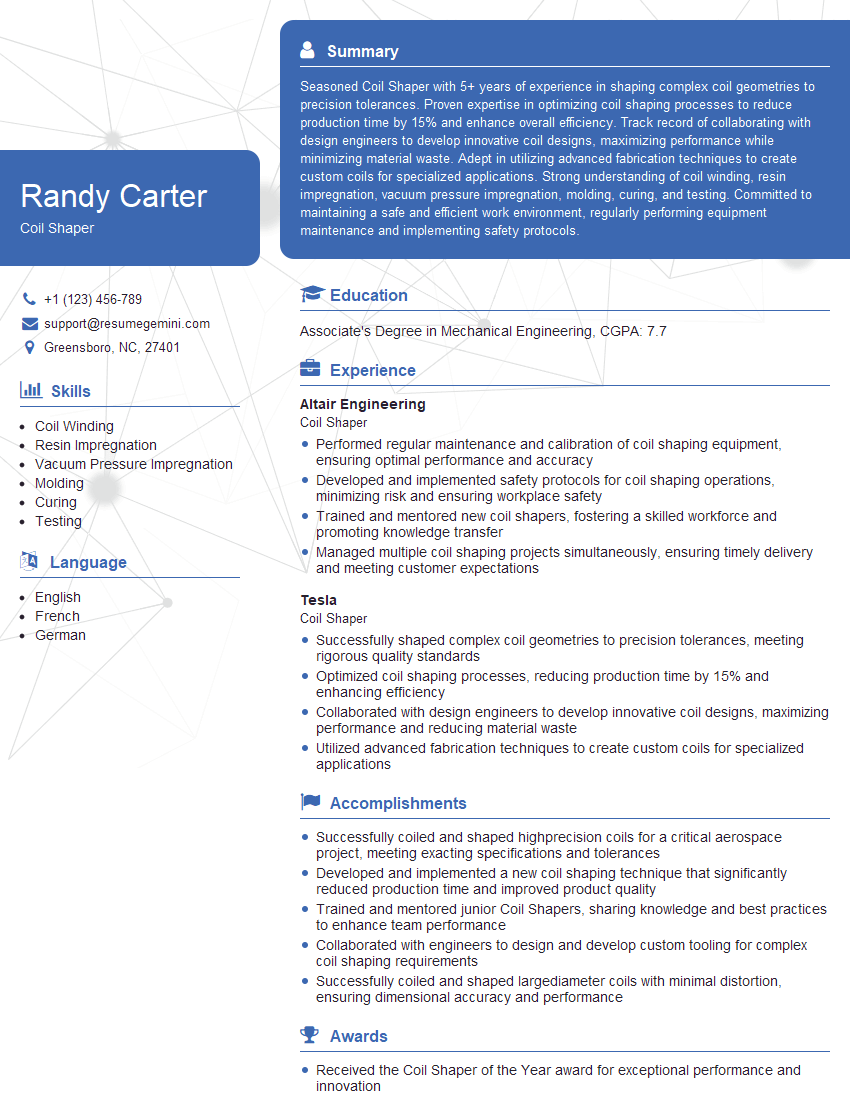

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Coil Shaper

1. Describe the process of coil shaping?

Coil shaping is the process of giving a specific shape to a metal coil. This process involves several steps:

- Uncoiling: The metal coil is first uncoiled from the reel.

- Straightening: The uncoiled metal is then straightened to remove any bends or curves.

- Slitting: The straightened metal is then slit into strips of the desired width.

- Shaping: The metal strips are then shaped using a variety of techniques, such as roll forming, press brake forming, or bending.

- Coiling: The shaped metal strips are then coiled back onto a reel.

2. What are the different types of coil shaping machines?

Roll Forming Machines:

- Use a series of rollers to gradually bend the metal into the desired shape.

- Suitable for producing long, continuous shapes with complex profiles.

Press Brake Forming Machines:

- Use a punch and die to bend the metal into the desired shape.

- Suitable for producing short, complex shapes with high precision.

Bending Machines:

- Use a variety of techniques, such as air bending, hydraulic bending, or roll bending, to bend the metal.

- Suitable for producing bends in straight metal strips or sheets.

3. What are the factors that affect the quality of coil shaping?

- Material properties: The thickness, strength, and ductility of the metal affect the ease of shaping.

- Machine settings: The speed, pressure, and temperature settings of the coil shaping machine can impact the quality of the finished product.

- Tooling: The design and condition of the rolls, punches, and dies used in the shaping process can affect the accuracy and precision of the finished product.

- Operator skill: The experience and skill of the operator can greatly influence the quality of the coil shaping.

4. What are the challenges in coil shaping?

- Springback: Metal tends to spring back to its original shape after being bent, which can affect the accuracy of the finished product.

- Tearing: If the metal is bent terlalu tightly or too quickly, it can tear.

- Wrinkling: If the metal is not properly supported during bending, it can wrinkle.

- Warping: If the metal is not properly heated or cooled during bending, it can warp.

5. What are the applications of coil shaping?

- Automotive industry: Coil shaping is used to produce a wide range of components, such as body panels, chassis parts, and exhaust systems.

- Construction industry: Coil shaping is used to produce roofing and siding panels, gutters, and downspouts.

- Appliance industry: Coil shaping is used to produce components for appliances such as refrigerators, stoves, and dishwashers.

- Aerospace industry: Coil shaping is used to produce components for aircraft, such as wings, fuselage panels, and engine nacelles.

6. What are the safety precautions that should be taken when operating a coil shaping machine?

- Wear appropriate safety gear: This includes safety glasses, gloves, and earplugs.

- Keep the work area clean and organized: This will help to prevent accidents.

- Inspect the machine before each use: This will help to identify any potential hazards.

- Follow the manufacturer’s instructions: This will help to ensure that the machine is operated safely.

- Never reach into the machine while it is running: This can result in serious injury.

7. What are the maintenance procedures that should be followed for a coil shaping machine?

- Regularly clean and lubricate the machine: This will help to prevent wear and tear.

- Inspect the rolls, punches, and dies regularly: This will help to identify any damage that needs to be repaired.

- Calibrate the machine regularly: This will help to ensure that the machine is producing accurate parts.

- Follow the manufacturer’s maintenance instructions: This will help to keep the machine running at peak performance.

8. What are the troubleshooting procedures for a coil shaping machine?

- If the machine is not producing accurate parts: Check the calibration of the machine and inspect the rolls, punches, and dies for damage.

- If the machine is making excessive noise: Check the lubrication of the machine and inspect the bearings for wear.

- If the machine is overheating: Check the cooling system of the machine and ensure that there is no blockage.

- If the machine is not working properly: Follow the manufacturer’s troubleshooting instructions and contact a qualified technician if necessary.

9. What are the latest trends in coil shaping technology?

- The use of more advanced materials: This includes materials such as high-strength steel, stainless steel, and aluminum.

- The use of more sophisticated machines: This includes machines that are capable of producing more complex shapes with greater accuracy and precision.

- The use of automation: This includes the use of robots and other automated systems to reduce labor costs and improve productivity.

- The use of digital technology: This includes the use of computer-aided design (CAD) and computer-aided manufacturing (CAM) systems to improve the efficiency and accuracy of the coil shaping process.

10. What are the future prospects for the coil shaping industry?

- The coil shaping industry is expected to grow steadily in the coming years: This growth will be driven by the increasing demand for metal components in a variety of industries.

- The development of new technologies will continue to drive the growth of the coil shaping industry: These technologies will make it possible to produce more complex shapes with greater accuracy and precision.

- The coil shaping industry is expected to become increasingly automated in the coming years: This will help to reduce labor costs and improve productivity.

- The coil shaping industry is expected to become more globalized in the coming years: This will allow companies to take advantage of lower labor costs in other countries.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Coil Shaper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Coil Shaper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Coil Shaper is entrusted with the crucial task of shaping and forming metal coils into intricate shapes and components. Their expertise ensures that these coils meet the precise specifications required for various applications.

1. Coil Shaping

The primary responsibility of a Coil Shaper is to operate specialized machinery to shape and form metal coils into desired shapes. This involves:

- Setting up and operating coil shaping machines to achieve specific dimensions and tolerances.

- Monitoring the shaping process to ensure that coils conform to design specifications.

- Adjusting machine settings and troubleshooting any issues that arise during the shaping process.

2. Quality Control

Coil Shapers also play a vital role in ensuring the quality of shaped coils. They are responsible for:

- Inspecting coils for defects and deviations from specifications.

- Conducting dimensional checks and measurements to verify accuracy.

- Maintaining quality control records and reporting any non-conformances.

3. Machine Maintenance

Coil Shapers are often responsible for maintaining and servicing the machines they operate. This includes:

- Performing regular maintenance tasks, such as lubrication and cleaning.

- Troubleshooting and repairing minor machine malfunctions.

- Assisting in major machine repairs and overhauls.

4. Safety and Compliance

Coil Shapers must strictly adhere to safety regulations and guidelines. Their responsibilities include:

- Following established safety protocols and wearing appropriate protective gear.

- Maintaining a clean and organized work area to minimize hazards.

- Complying with environmental regulations related to coil shaping processes.

Interview Tips

To ace a Coil Shaper interview, candidates should focus on highlighting their technical skills, attention to detail, and passion for manufacturing. Here are some tips:

1. Research the Company and Industry

Research the company’s history, products, and industry to demonstrate your genuine interest and knowledge of the field. This will show the interviewer that you are well-informed and have a clear understanding of the company’s operations.

2. Quantify Your Experience

Use specific numbers and metrics to quantify your experience and accomplishments as a Coil Shaper. For example, instead of saying “I shaped coils,” provide details such as “I shaped over 10,000 coils per month, achieving a 99% accuracy rate.”

3. Showcase Your Attention to Detail

Emphasize your meticulous attention to detail and ability to maintain high standards of quality. Provide examples of how you have identified and resolved discrepancies in coil dimensions or ensured compliance with industry standards.

4. Discuss Your Technical Skills

Highlight your proficiency with various coil shaping machinery and software. Discuss your knowledge of different types of coils, their applications, and the techniques used to shape them.

5. Prepare for Common Interview Questions

Anticipate common interview questions related to coil shaping, quality control, safety, and your experience. Prepare thoughtful answers that showcase your expertise and demonstrate your suitability for the role.

6. Be Enthusiastic and Confident

Express your passion for manufacturing and your desire to contribute to the company’s success. Be confident in your abilities and demonstrate your eagerness to learn and grow within the organization.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Coil Shaper interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!