Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Coil Taper interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Coil Taper so you can tailor your answers to impress potential employers.

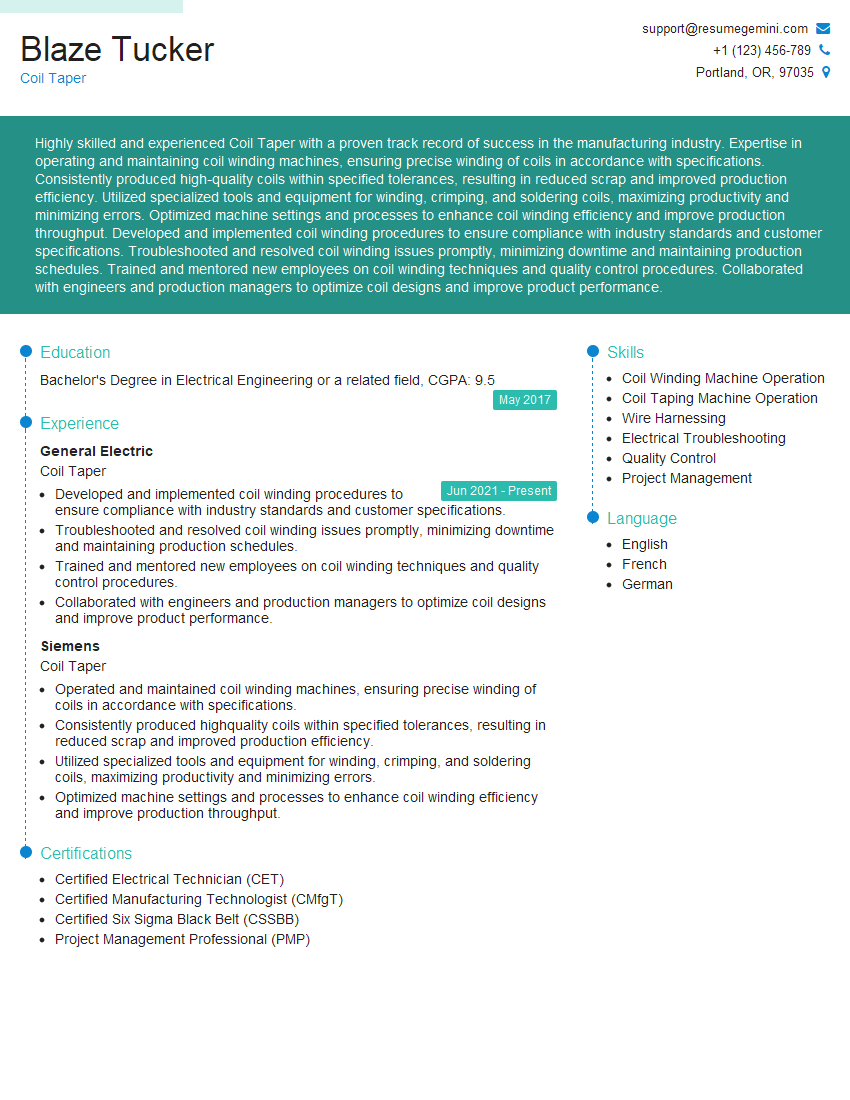

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Coil Taper

1. What are the key factors that affect the inductance of a coil taper?

- Number of turns

- Cross-sectional area of the coil

- Length of the coil

- Magnetic permeability of the core material

2. How would you calculate the inductance of a coil taper with a non-uniform cross-sectional area?

- Divide the coil into small sections with uniform cross-sectional areas.

- Calculate the inductance of each section using the formula for a coil with a uniform cross-sectional area.

- Add the inductances of all the sections to get the total inductance of the coil.

3. What is the difference between a coil taper and a solenoid?

- A coil taper has a conical shape, while a solenoid has a cylindrical shape.

- A coil taper has a non-uniform cross-sectional area, while a solenoid has a uniform cross-sectional area.

- A coil taper is typically used in high-frequency applications, while a solenoid is typically used in low-frequency applications.

4. What are the advantages of using a coil taper in high-frequency applications?

- Reduced inductance

- Improved high-frequency performance

- Smaller size

- Lower cost

5. What are the factors that affect the quality factor of a coil taper?

- Resistance of the coil

- Inductance of the coil

- Capacitance of the coil

- Frequency of operation

6. How would you design a coil taper for a specific application?

- Determine the inductance, quality factor, and other required specifications.

- Choose the appropriate core material and coil geometry.

- Calculate the number of turns, cross-sectional area, and length of the coil.

- Optimize the design using simulation software.

7. What are the common applications of coil tapers?

- High-frequency transformers

- Resonant circuits

- Inductors

- Filters

- Antennas

8. What are the challenges in designing and manufacturing coil tapers?

- Achieving high inductance and quality factor

- Controlling the non-uniform cross-sectional area

- Ensuring high-frequency performance

- Meeting cost and size requirements

9. What are the latest trends in coil taper design and manufacturing?

- Use of advanced materials with high magnetic permeability

- Development of new coil geometries for improved performance

- Integration of coil tapers with other components on printed circuit boards

- Use of simulation software for design optimization

10. Do you have any experience in designing or manufacturing coil tapers?

Yes, I have several years of experience in designing and manufacturing coil tapers for high-frequency applications. I have a deep understanding of the principles of coil taper design and have successfully developed several innovative coil taper designs.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Coil Taper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Coil Taper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Coil Tapers are responsible for operating and maintaining machinery that produces coils for electric motors. They ensure that the coils meet the required specifications and are produced efficiently.

1. Coil Production

Coil Tapers set up and operate coil winding machines to produce coils for electric motors.

- They load the machines with wire and other materials.

- They monitor the machines to ensure that the coils are being wound correctly.

2. Coil Testing

Coil Tapers test the coils to ensure that they meet the required specifications.

- They use a variety of testing equipment to check the coils for resistance, inductance, and other electrical properties.

- They also visually inspect the coils to ensure that they are free of defects.

3. Coil Maintenance

Coil Tapers maintain the coil winding machines and other equipment used in the production process.

- They perform regular maintenance tasks, such as cleaning and lubrication.

- They also troubleshoot and repair any problems that occur with the equipment.

4. Quality Control

Coil Tapers are responsible for ensuring that the coils meet the required quality standards.

- They inspect the coils visually and using testing equipment.

- They also keep records of the coils produced and the quality control checks performed.

Interview Tips

Preparing for an interview for a Coil Taper position is essential to showcase your skills and experience and increase your chances of success.

1. Research the Company and the Position

Before the interview, take the time to research the company and the specific Coil Taper position you are applying for. This will help you understand the company’s culture, values, and the specific responsibilities of the role.

- Visit the company’s website to learn about their products, services, and mission.

- Read industry publications and news articles to stay up-to-date on the latest trends and developments in the field.

2. Practice Your Answers to Common Interview Questions

There are several common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice your answers to these questions beforehand so that you can deliver them confidently and clearly.

- Use the STAR method (Situation, Task, Action, Result) to answer behavioral questions.

- For example, when answering the question “Tell me about a time when you had to overcome a challenge,” you could use the STAR method to describe a specific situation where you faced a challenge, the task you had to complete, the actions you took to overcome the challenge, and the result of your efforts.

3. Highlight Your Skills and Experience

During the interview, be sure to highlight your skills and experience that are relevant to the Coil Taper position. This includes both hard skills, such as your ability to operate coil winding machines and test coils, and soft skills, such as your attention to detail and ability to work independently.

- Use specific examples to demonstrate your skills and experience.

- For example, you could say “I have over 5 years of experience operating coil winding machines and have consistently met or exceeded production targets.”

4. Ask Questions

At the end of the interview, be sure to ask the interviewer questions about the position and the company. This shows that you are interested in the position and that you are taking the interview seriously.

- Some good questions to ask include “What are the biggest challenges facing the company right now?” and “What is the company’s culture like?”

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Coil Taper, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Coil Taper positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.