Are you gearing up for an interview for a Coil Winder, Repair position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Coil Winder, Repair and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

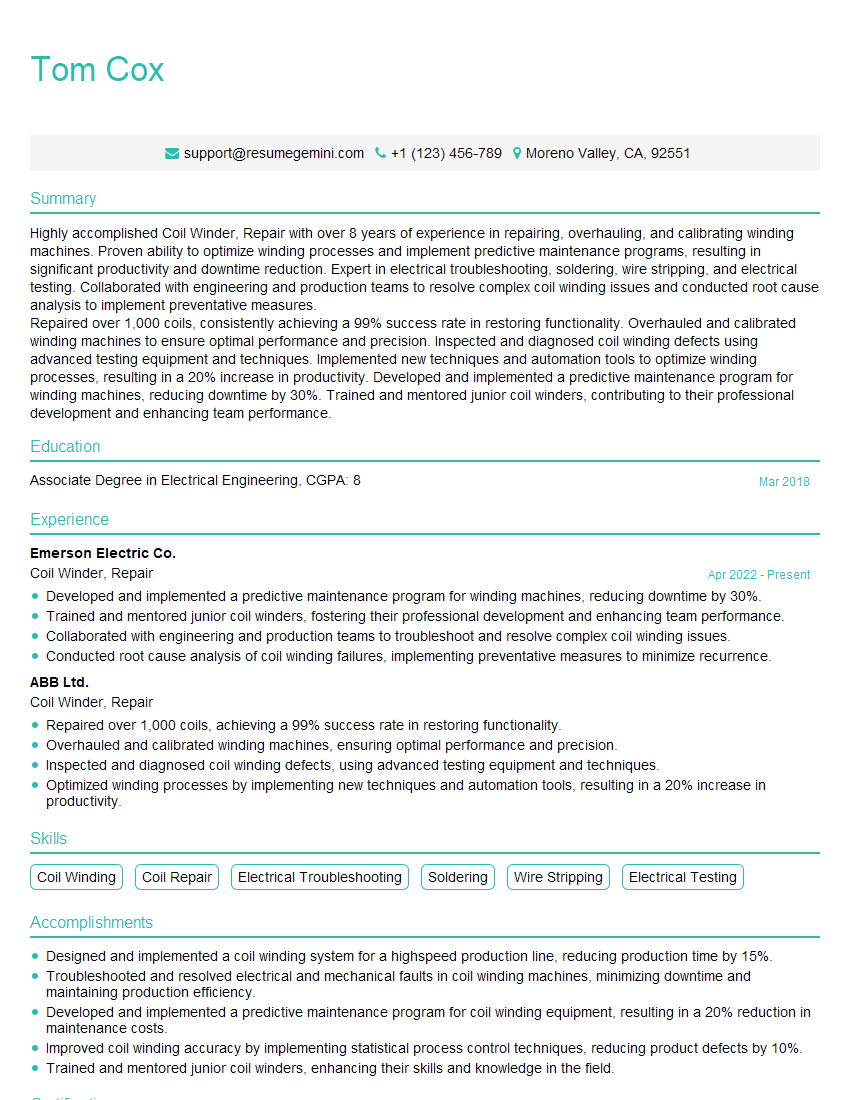

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Coil Winder, Repair

1. What are the different types of coil winding machines and their applications?

There are various types of coil winding machines, each designed for specific applications. Some common types include:

- CNC Coil Winding Machines: Computer-controlled machines for high-precision, complex coil winding.

- Linear Coil Winding Machines: For producing coils with linear windings, such as solenoids.

- Toroidal Coil Winding Machines: Used to wind coils in a toroidal shape, commonly found in transformers.

- Bobbin Coil Winding Machines: Suitable for winding coils onto bobbins or spools.

- Multi-Head Coil Winding Machines: Machines with multiple winding heads for simultaneous winding of multiple coils.

2. What are the key factors to consider when selecting a coil winding machine?

Factors for Selecting a Coil Winding Machine

- Coil Specifications: Coil size, shape, number of turns, wire gauge.

- Production Volume: Required output rate and batch size.

- Precision Requirements: Tolerance levels for coil geometry and winding parameters.

- Wire Material: Type of wire used, such as copper, aluminum, or enameled wire.

- Machine Capabilities: Features, such as winding speed, tension control, and automation options.

3. What is the process of coil winding repair?

Coil winding repair involves the following steps:

- Inspection: Examine the damaged coil to identify the cause of failure.

- Coil Rewinding: Rewind the coil to the original specifications, using proper wire and insulation.

- Insulation Repair: Repair any damaged insulation using heat-shrink tubing or other materials.

- Testing: Conduct electrical tests to ensure proper functionality and insulation integrity.

4. What are the common causes of coil winding failures?

Common causes of coil winding failures include:

- Overheating: Excessive current flow or poor heat dissipation.

- Insulation Breakdown: Damage to the insulation layer, leading to short circuits.

- Mechanical Stress: Vibration, shock, or excessive tension.

- Environmental Factors: Moisture, dust, or corrosive chemicals.

- Manufacturing Defects: Imperfections in the winding process or materials.

5. How do you ensure the quality of coil windings?

Quality assurance for coil windings includes:

- Visual Inspection: Checking for defects, correct winding direction, and insulation integrity.

- Electrical Testing: Measuring resistance, inductance, and insulation resistance.

- Environmental Testing: Exposing coils to heat, moisture, and vibration to assess durability.

- Process Control: Monitoring winding parameters and adhering to established procedures.

- Training and Certification: Ensuring coil winders are skilled and certified.

6. What are the different types of insulation materials used in coil windings?

Common insulation materials for coil windings include:

- Enameled Wire: Coated with a thin layer of enamel for electrical insulation.

- Heat-Shrink Tubing: Thermoplastic material that shrinks when heated, providing insulation and strain relief.

- Varnish: Liquid or solid varnish applied to coils for insulation and moisture resistance.

- Epoxy: A resin that cures to form a hard, protective coating on coils.

- Kapton Tape: High-temperature resistant tape used for insulation and protection.

7. What is the role of slot wedges in coil windings?

Slot wedges are used in coil windings to:

- Secure Coils in Slots: Prevent coils from moving or vibrating within stator slots.

- Maintain Insulation Integrity: Separate coils and protect insulation from damage.

- Reduce Heat and Losses: Provide ventilation channels for heat dissipation, reducing eddy current losses.

- Improve Mechanical Strength: Reinforce the structure of the coil windings.

8. How do you determine the appropriate wire size for a coil winding?

Factors to consider when determining wire size for coil windings:

- Current Rating: Wire size must be adequate to handle the expected current flow.

- Temperature Rise: Wire insulation must withstand the operating temperature of the coil.

- Space Constraints: Wire size should fit into the available space in the windings.

- Cost Considerations: Larger wire sizes are generally more expensive.

9. What are the safety precautions to observe when working with coil winding machines?

Safety precautions for coil winding machines include:

- Wear Protective Gear: Safety glasses, gloves, and appropriate clothing.

- Follow Lockout/Tagout Procedures: Isolate machines from power before maintenance or repairs.

- Avoid Loose Clothing: Prevent clothing from getting caught in machinery.

- Maintain Clear Work Area: Keep the work area free from tripping hazards and debris.

- Inspect Machines Regularly: Check for any damage or malfunction before operation.

10. How do you stay updated on the latest technologies and best practices in coil winding?

Methods for staying updated on coil winding technologies and best practices:

- Attend Industry Events: Conferences, exhibitions, and workshops.

- Read Trade Journals and Publications: Stay informed about new products, techniques, and industry trends.

- Participate in Online Forums and Discussion Groups: Engage with other professionals and exchange knowledge.

- Seek Training and Certification: Enhance skills through specialized training programs.

- Collaborate with Suppliers and Experts: Build relationships with industry professionals for knowledge sharing and support.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Coil Winder, Repair.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Coil Winder, Repair‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Coil Winders, Repair play a crucial role in maintaining and repairing electrical components. Their key job responsibilities include:

1. Repairing and Rewinding Coils

Troubleshoot and diagnose faulty coils, identify the cause of damage, and determine the appropriate repair or replacement procedures.

- Repair damaged or defective coils by replacing insulation, windings, or other components.

- Rewind coils to restore proper functioning and meet original specifications.

2. Testing and Inspecting Coils

Ensure that repaired or rewound coils meet quality standards and specifications.

- Perform electrical tests using specialized equipment to verify coil resistance, inductance, and other parameters.

- Inspect coils for any defects, damage, or other issues that could affect performance.

3. Fabricating Coils

Design and create new coils based on customer requirements or specifications.

- Select appropriate materials, such as copper wire, insulation, and core materials.

- Use winding machines to create coils and ensure proper winding techniques and specifications.

4. Maintaining and Troubleshooting Equipment

Maintain and troubleshoot coil winding and repair equipment.

- Clean and calibrate equipment to ensure accuracy and optimal performance.

- Identify and resolve equipment malfunctions or issues to minimize downtime.

Interview Preparation Tips

To ace the interview for a Coil Winder, Repair position, consider the following preparation tips:

1. Research the Company and Role

Thoroughly research the company’s background, industry, and specific requirements for the Coil Winder, Repair position. This will help you understand their business and the role’s expectations.

- Visit the company’s website, read their mission statement, and learn about their products or services.

- Review the job description carefully, identifying the key responsibilities and qualifications required.

2. Highlight Relevant Experience and Skills

Emphasize your experience and skills that are directly related to the key job responsibilities. Use specific examples to demonstrate your abilities.

- Highlight your experience in repairing, rewinding, or fabricating coils.

- Mention any proficiency in electrical testing, inspection, or troubleshooting techniques.

3. Prepare for Technical Questions

Be prepared to answer technical questions related to coil winding and repair. Review basic electrical concepts, testing procedures, and repair techniques.

- Practice explaining the process of rewinding a coil using different winding techniques.

- Prepare to discuss methods for testing coil resistance, inductance, and other electrical parameters.

4. Show Enthusiasm and Passion

Convey your interest and passion for coil winding and repair. Demonstrate your understanding of the importance of this role in maintaining electrical systems and ensuring quality.

- Share examples of how your work has contributed to successful repairs or projects.

- Express your eagerness to learn and expand your knowledge in the field.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Coil Winder, Repair, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Coil Winder, Repair positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.