Feeling lost in a sea of interview questions? Landed that dream interview for Coil Winding Machines Set-Up Mechanic but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Coil Winding Machines Set-Up Mechanic interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

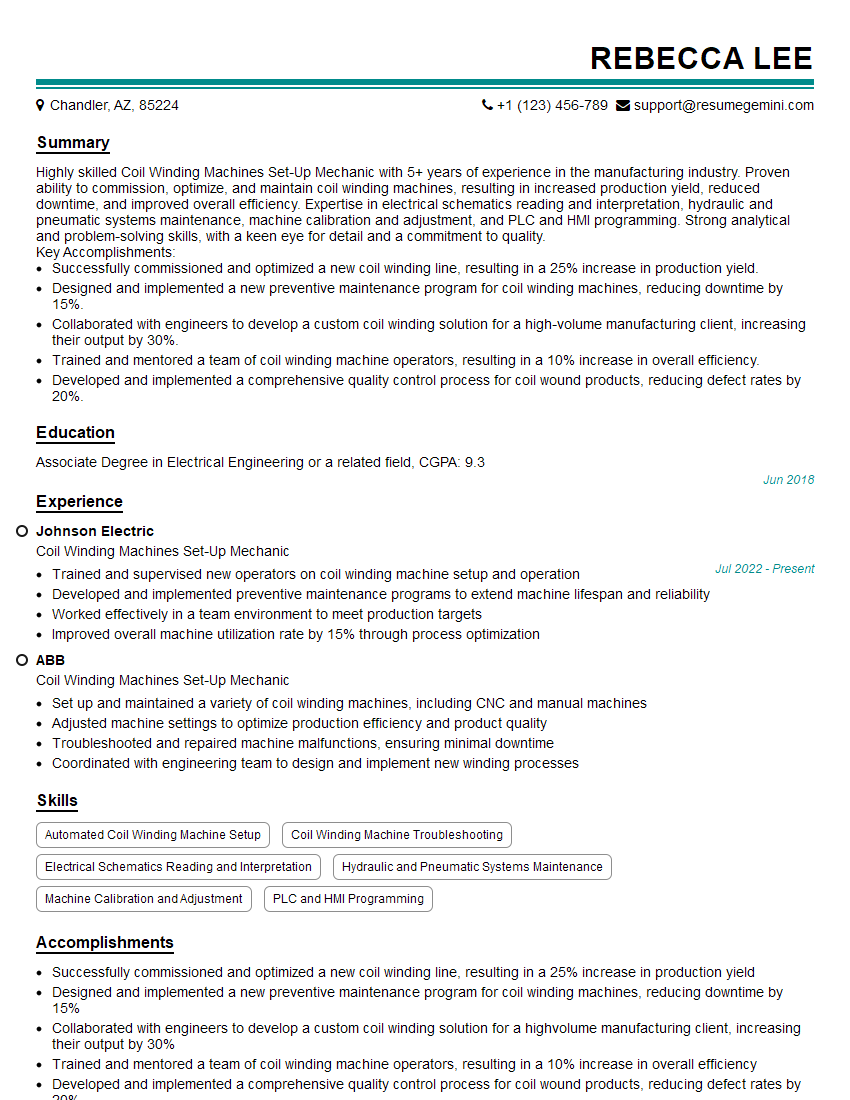

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Coil Winding Machines Set-Up Mechanic

1. How would you ensure the proper tension of the wire during coil winding?

- Utilize tension measuring devices such as tensiometers or dancing arm tensioners to accurately monitor and adjust wire tension.

- Calibrate tensioning systems regularly to maintain optimal tension levels.

- Inspect wire spools for any defects or damage that could affect tension uniformity.

- Consider the wire material’s properties and adjust tension accordingly to prevent breakage or deformation.

2. Describe the different types of coil winding machines and their applications.

CNC Coil Winding Machines:

- Computer-controlled, offering high precision and repeatability for complex coil designs.

- Used for mass production of coils with intricate patterns and precise specifications.

Manual Coil Winding Machines:

- Operated manually, requiring skilled technicians for accurate winding.

- Suitable for small-scale production or prototyping.

Automatic Coil Winding Machines:

- Automated systems with programmable winding parameters.

- Fast and efficient for high-volume production of standard coils.

3. Explain the process of troubleshooting a coil winding machine.

- Identify and isolate the problem by observing error messages, machine behavior, and component performance.

- Consult technical manuals and schematics to diagnose the issue.

- Perform electrical, mechanical, or software troubleshooting techniques to pinpoint the faulty component or malfunctioning process.

- Replace or repair damaged parts, adjust settings, or recalibrate the machine to resolve the issue.

4. How do you maintain and calibrate coil winding machines to ensure optimal performance?

- Regularly clean and lubricate machine components to minimize friction and wear.

- Inspect and replace worn parts such as tensioners, guides, and drive belts.

- Calibrate tensioning systems, speed controllers, and other critical parameters to meet specified tolerances.

- Follow manufacturer’s maintenance schedules and guidelines.

5. Explain the importance of wire insulation and how to select the appropriate insulation for different coil winding applications.

- Insulation prevents electrical shorts and ensures the coil’s safe operation.

- Consider factors such as voltage rating, temperature range, space constraints, and environmental conditions when selecting insulation.

- Common insulation materials include enamel, varnish, polyester, and epoxy.

6. What techniques do you use to achieve accurate coil winding patterns and minimize winding defects?

- Use precision winding heads with adjustable traverse mechanisms.

- Monitor and adjust wire tension throughout the winding process.

- Employ winding programs and software to optimize coil geometry.

- Inspect coils for defects such as shorts, opens, and uneven spacing.

7. Explain how you would evaluate the quality of a coil winding and identify potential areas for improvement.

- Inspect the coil for physical defects, insulation integrity, and dimensional accuracy.

- Perform electrical tests to measure resistance, inductance, and capacitance.

- Analyze the winding pattern for consistency and uniformity.

- Identify areas where efficiency can be improved, such as reducing wire waste or optimizing winding speed.

8. What safety precautions do you follow when operating coil winding machines?

- Wear appropriate personal protective equipment such as gloves, safety glasses, and earplugs.

- Ensure the machine is properly grounded and electrically safe.

- Keep the work area clean and organized to prevent tripping hazards.

- Follow lockout/tagout procedures during maintenance or repairs.

9. How do you stay updated with the latest advancements in coil winding technology?

- Attend industry conferences and seminars.

- Read technical publications and research papers.

- Collaborate with other coil winding professionals.

- Explore online resources and manufacturer websites.

10. Describe a challenging coil winding project you have worked on and how you overcame the challenges.

[Provide a specific example of a complex coil winding project, describing the challenges faced and the solutions implemented. This will showcase your problem-solving skills and technical expertise.]

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Coil Winding Machines Set-Up Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Coil Winding Machines Set-Up Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Coil Winding Machines Set-Up Mechanics are responsible for the installation, maintenance, and repair of coil winding machines. They work with engineers and other technicians to ensure that the machines are operating properly, producing high-quality coils, and meeting production targets.

1. Installing and Maintaining Coil Winding Machines

Coil Winding Machines Set-Up Mechanics install and maintain coil winding machines according to the manufacturer’s specifications. They level the machines, connect the electrical and mechanical components, and ensure that the machines are properly lubricated and calibrated.

- Install new coil winding machines and retrofit existing machines with new components.

- Maintain coil winding machines by performing regular inspections, cleaning, and lubrication.

- Troubleshoot and repair coil winding machines, identify and fix any problems.

2. Programming and Operating Coil Winding Machines

Coil Winding Machines Set-Up Mechanics program and operate coil winding machines to produce coils that meet the required specifications. They enter the winding parameters into the machine’s computer, load the wire onto the machine, and start the winding process.

- Program coil winding machines to produce coils with the correct number of turns, pitch, and other specifications.

- Operate coil winding machines to produce coils at the required speed and tension.

- Monitor coil winding machines to ensure that they are operating properly and producing high-quality coils.

3. Inspecting and Testing Coils

Coil Winding Machines Set-Up Mechanics inspect and test coils to ensure that they meet the required specifications. They visually inspect the coils for any defects, measure the electrical resistance and inductance of the coils, and perform other tests to ensure that the coils are functioning properly.

- Inspect coils for any defects, such as broken wires, shorts, or opens.

- Measure the electrical resistance and inductance of coils to ensure that they meet the required specifications.

- Perform other tests on coils, such as insulation resistance tests and high-potential tests.

4. Troubleshooting and Repairing Coil Winding Machines

Coil Winding Machines Set-Up Mechanics troubleshoot and repair coil winding machines to ensure that they are operating properly. They identify the source of the problem, replace or repair the faulty components, and test the machine to ensure that it is functioning properly.

- Identify the source of problems with coil winding machines.

- Replace or repair faulty components on coil winding machines.

- Test coil winding machines to ensure that they are functioning properly after repairs.

Interview Tips

An interview for a Coil Winding Machines Set-Up Mechanic position can be competitive, so it is important to prepare in advance. Here are some tips to help you ace your interview:

1. Research the Company and the Position

Before the interview, take some time to research the company and the specific position you are applying for. This will help you understand the company’s culture, goals, and expectations for the role. You can find information about the company on its website, social media pages, and press releases. You can also find information about the specific position by reading the job posting and talking to the recruiter.

- Research the company’s website, social media pages, and press releases.

- Read the job posting carefully and make sure you understand the requirements.

- Talk to the recruiter to get more information about the position and the company.

2. Practice Answering Common Interview Questions

There are some common interview questions that you are likely to be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”. It is helpful to practice answering these questions in advance so that you can deliver clear and concise responses. You can practice answering these questions with a friend or family member, or you can record yourself and listen back to your answers.

- Practice answering common interview questions such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”.

- Use the STAR method to answer interview questions. This method involves describing a situation, task, action, and result.

- Be specific and provide examples when answering interview questions.

3. Dress Professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for an office environment. Avoid wearing casual clothes, such as jeans or t-shirts. You should also avoid wearing clothing that is too revealing or too tight.

- Wear clean, pressed clothes that are appropriate for an office environment.

- Avoid wearing casual clothes, such as jeans or t-shirts.

- Avoid wearing clothing that is too revealing or too tight.

4. Be Punctual

Punctuality is important for any job interview. Make sure to arrive for your interview on time. If you are running late, call or email the interviewer to let them know. It is also important to be prepared to wait for a few minutes before your interview begins. This is a good time to review your resume and notes.

- Arrive for your interview on time.

- If you are running late, call or email the interviewer to let them know.

- Be prepared to wait for a few minutes before your interview begins. This is a good time to review your resume and notes.

Next Step:

Now that you’re armed with the knowledge of Coil Winding Machines Set-Up Mechanic interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Coil Winding Machines Set-Up Mechanic positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini