Are you gearing up for an interview for a Coil Wrapper position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Coil Wrapper and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

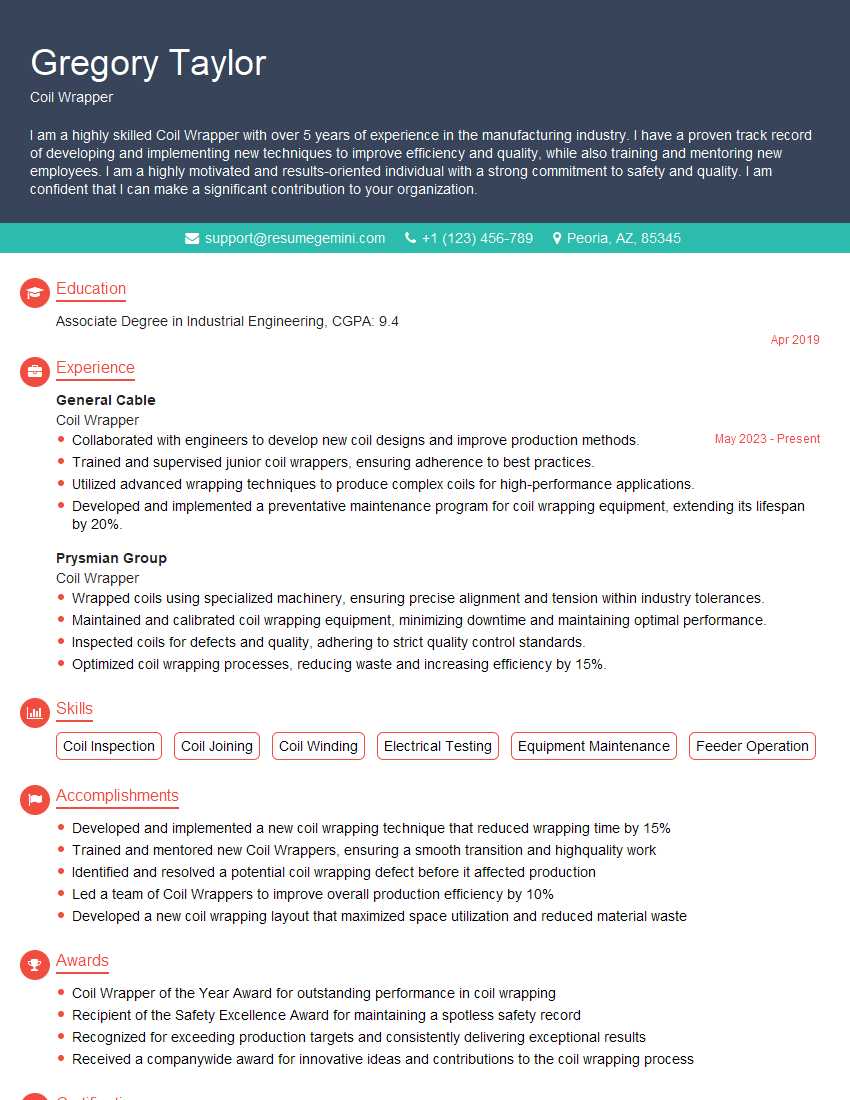

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Coil Wrapper

1. Describe the process of winding a coil?

The process of winding a coil involves several steps:

- Preparation: Determine the coil’s specifications, such as number of turns, wire gauge, and core size.

- Core selection: Choose an appropriate core material (e.g., ferrite, iron) and size based on the coil’s inductance and current requirements.

- Wire selection: Select a wire with the correct gauge, insulation, and temperature rating.

- Winding: Use a winding machine or manual winding technique to wrap the wire around the core in a specified pattern and direction.

- Terminations: Secure the ends of the winding using appropriate methods, such as soldering or crimping.

- Testing: Perform electrical tests (e.g., resistance, inductance) to ensure the coil meets desired specifications.

2. What factors affect the inductance of a coil?

Number of turns:

- Higher number of turns increases inductance.

Core material:

- Materials with higher permeability (e.g., iron) increase inductance.

Core size:

- Larger core size increases inductance.

Air gap:

- Presence of an air gap reduces inductance.

3. What techniques can be used to reduce eddy current losses in coils?

Eddy current losses can be reduced by:

- Lamination: Using laminated cores, which are made of thin sheets of material stacked together.

- Core shape: Designing cores with non-rectangular shapes to discourage eddy current flow.

- Insulation: Insulating the core to prevent direct contact between layers.

4. How do you determine the appropriate winding pattern for a coil?

The winding pattern is determined based on factors such as:

- Inductance requirements: Different patterns (e.g., single layer, multilayer) can affect inductance.

- Current capacity: Patterns that distribute current evenly minimize losses.

- Core shape: The shape and size of the core dictate the winding pattern.

5. What is the purpose of using a bobbin in coil winding?

- Provides a form and support for the windings.

- Insulates the windings from the core.

- Facilitates winding and handling.

- Protects the windings from damage.

6. What safety precautions should be taken when working with high-voltage coils?

- PPE: Wear appropriate personal protective equipment (e.g., gloves, goggles).

- Grounding: Ensure all equipment and personnel are grounded.

- Insulation: Use high-voltage insulation materials.

- Testing: Perform safety tests before energizing the coil.

- Training: Only trained personnel should handle high-voltage coils.

7. How do you troubleshoot a coil that is not performing as expected?

Troubleshooting involves:

- Visual inspection: Check for loose connections, damaged insulation, or winding errors.

- Electrical tests: Perform resistance, inductance, and voltage tests to identify any deviations.

- Core evaluation: Check the core for any cracks, shorts, or breaks.

- Winding analysis: Examine the winding pattern and check for incorrect turns or insulation issues.

8. What is the difference between a transformer coil and an inductor coil?

- Has two or more windings.

- Used to transfer energy between circuits.

- Has a single winding.

- Used to store energy in a magnetic field.

Transformer coil:

Inductor coil:

9. What quality control measures are important in coil winding?

- Dimensional accuracy: Ensuring that coils meet specified dimensions.

- Electrical properties: Testing and verifying inductance, resistance, and voltage withstand.

- Physical inspection: Checking for winding defects, insulation damage, and loose connections.

- Documentation: Maintaining records of winding parameters and test results.

10. How do you stay updated on the latest advancements in coil winding technology?

- Industry publications: Reading trade magazines and technical journals.

- Conferences and seminars: Attending events where new technologies are presented.

- Online forums and discussions: Engaging with industry professionals and learning from their experiences.

- Training courses: Participating in workshops and seminars to enhance knowledge.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Coil Wrapper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Coil Wrapper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities of a Coil Wrapper

A Coil Wrapper is responsible for wrapping coils of wire, tubing, or other materials around a mandrel or core, as per the specified dimensions and tolerances. This role plays a crucial role in the manufacturing industry, ensuring that coils meet the required standards and specifications.

1. Coil Preparation and Handling

The Coil Wrapper is responsible for receiving, inspecting, and preparing coils of materials for wrapping. This includes:

- Verifying the dimensions, specifications, and quality of incoming coils.

- Unloading coils from delivery trucks or storage areas.

- Positioning coils on the wrapping machine or mandrel.

2. Coil Wrapping Process

The Coil Wrapper operates the wrapping machine to wrap coils around the mandrel or core. This process involves:

- Setting up the wrapping machine according to the required specifications.

- Controlling the tension, speed, and pitch of the wrapping.

- Monitoring the wrapping process to ensure proper tension, alignment, and consistency.

3. Quality Control and Inspection

The Coil Wrapper is responsible for conducting quality control checks on the wrapped coils. This includes:

- Inspecting the wrapped coils for defects, such as breaks, gaps, or overlaps.

- Measuring and verifying the dimensions and tolerances of the wrapped coils.

- Maintaining records of quality control inspections.

4. Equipment Maintenance and Troubleshooting

The Coil Wrapper is responsible for performing basic maintenance and troubleshooting on the wrapping equipment. This includes:

- Cleaning and lubricating the wrapping machine.

- Identifying and resolving minor equipment malfunctions.

- Reporting major equipment issues to supervisors.

Interview Preparation Tips for Coil Wrappers

Preparing thoroughly for your Coil Wrapper interview can significantly increase your chances of success. Here are some tips to help you ace the interview:

1. Research the Company and Position

Before the interview, take the time to research the company you’re applying to and the specific Coil Wrapper position. This will demonstrate your interest in the company and the role, and it will enable you to ask informed questions during the interview.

2. Practice Your Answers to Common Interview Questions

There are several common interview questions that you can expect to be asked, such as “Tell me about yourself,” “Why are you interested in this position?” and “What are your strengths and weaknesses?” Prepare your answers to these questions in advance so that you can deliver them confidently and effectively.

3. Highlight Your Relevant Skills and Experience

In your interview, be sure to highlight the skills and experience that are most relevant to the Coil Wrapper position. For example, emphasize your experience with coil wrapping machines, your attention to detail, and your ability to work independently.

4. Dress Professionally and Arrive on Time

First impressions matter, so make sure to dress professionally for your interview. Also, be sure to arrive on time to show that you respect the interviewer’s time. These small details can make a positive impact on the interviewer.

5. Ask Questions at the End of the Interview

At the end of the interview, be sure to ask the interviewer any questions you have about the position or the company. This shows that you’re engaged in the interview and that you’re interested in learning more about the opportunity.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Coil Wrapper interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!