Are you gearing up for an interview for a Coiled Coil Inspector position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Coiled Coil Inspector and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

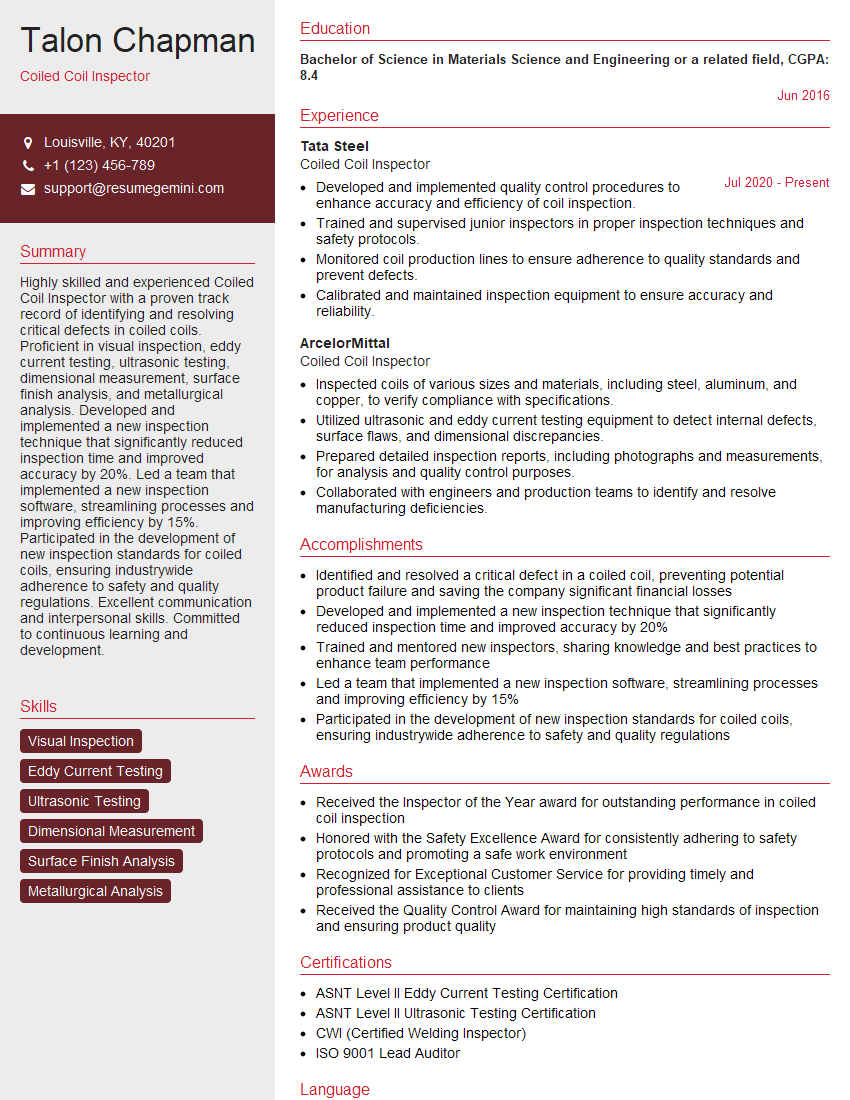

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Coiled Coil Inspector

1. Explain the different types of defects that can occur in coiled coil and how to identify them?

- Surface defects: these include scratches, dents, pits, and cracks. They can be identified visually or by using non-destructive testing methods.

- Internal defects: these include inclusions, voids, and laminations. They can be identified using ultrasonic testing or radiographic testing.

- Dimensional defects: these include variations in thickness, width, and length. They can be identified using calipers, micrometers, or other measuring tools.

2. What are the different inspection methods used for coiled coil?

Visual inspection

- This is the most basic inspection method and involves looking for defects on the surface of the coil.

- It can be used to identify surface defects such as scratches, dents, and pits.

Non-destructive testing

- This involves using specialized equipment to inspect the coil without damaging it.

- Methods such as ultrasonic testing and radiographic testing can be used to identify internal defects such as inclusions, voids, and laminations.

Dimensional inspection

- This involves measuring the thickness, width, and length of the coil to ensure that it meets specifications.

- Calipers, micrometers, and other measuring tools can be used for this purpose.

3. What are the different standards used for coiled coil inspection?

- ASTM A941: Standard Specification for High-Strength, Low-Alloy Columbium-Vanadium Steels of Structural Quality

- ASTM A1008: Standard Specification for Cold-Formed Welded and Seamless Carbon Steel Structural Tubing in Rounds and Shapes

- API 5L: Specification for Line Pipe

- AWS D1.1: Structural Welding Code – Steel

4. What are the different factors that can affect the quality of coiled coil?

- Material properties: the chemical composition and mechanical properties of the steel used to make the coil can affect its quality.

- Manufacturing process: the way the coil is manufactured can also affect its quality. Factors such as the temperature and speed of the rolling process can all have an impact.

- Storage and handling: the way the coil is stored and handled can also affect its quality. Exposure to moisture, heat, or cold can all damage the coil.

5. What are the different quality control procedures that can be used to ensure the quality of coiled coil?

- Visual inspection: this can be used to identify surface defects such as scratches, dents, and pits.

- Non-destructive testing: this can be used to identify internal defects such as inclusions, voids, and laminations.

- Dimensional inspection: this can be used to ensure that the coil meets specifications for thickness, width, and length.

- Mechanical testing: this can be used to assess the strength and other mechanical properties of the coil.

6. What are the different types of equipment used for coiled coil inspection?

- Visual inspection equipment: this includes magnifying glasses, flashlights, and cameras.

- Non-destructive testing equipment: this includes ultrasonic testing equipment, radiographic testing equipment, and eddy current testing equipment.

- Dimensional inspection equipment: this includes calipers, micrometers, and other measuring tools.

- Mechanical testing equipment: this includes tensile testing machines, hardness testers, and impact testing machines.

7. What are the different safety precautions that should be taken when inspecting coiled coil?

- Wear appropriate safety gear: this includes hard hats, safety glasses, gloves, and steel-toed boots.

- Be aware of your surroundings: be aware of the location of overhead hazards, such as cranes and forklifts.

- Use caution when handling coiled coil: coiled coil can be heavy and unwieldy, so it is important to use caution when handling it.

- Follow all safety procedures: it is important to follow all safety procedures that are in place at the inspection facility.

8. What are the different challenges that can be encountered when inspecting coiled coil?

- Surface defects: surface defects can be difficult to identify, especially if they are small or shallow.

- Internal defects: internal defects can be difficult to identify without using non-destructive testing equipment.

- Dimensional defects: dimensional defects can be difficult to measure accurately, especially if the coil is large or heavy.

- Safety hazards: coiled coil can be heavy and unwieldy, so it is important to be aware of the safety hazards involved in handling it.

9. What are the different skills and qualifications that are required for a coiled coil inspector?

- Knowledge of coiled coil manufacturing and inspection standards

- Experience in using coiled coil inspection equipment

- Strong attention to detail

- Ability to work independently and as part of a team

- Excellent communication and interpersonal skills

10. What are the different career opportunities for a coiled coil inspector?

- Quality control inspector

- Non-destructive testing technician

- Metallurgical engineer

- Sales representative

- Technical writer

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Coiled Coil Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Coiled Coil Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Coiled Coil Inspectors play a pivotal role in ensuring the quality and integrity of coiled steel products. Their responsibilities encompass various aspects of inspection, testing, and monitoring to guarantee the adherence to established standards and customer specifications.

1. Inspection and Verification

Inspect and verify coiled steel products for dimensional accuracy, surface quality, metallurgical properties, and compliance with relevant codes and regulations.

- Utilize specialized measuring equipment such as micrometers, calipers, and go/no-go gauges to assess dimensions and tolerances.

- Visually examine surface finishes for defects, scratches, pits, or other imperfections using trained observation skills.

- Conduct non-destructive tests (NDT) to evaluate the internal structure and properties of the steel, such as ultrasonic testing (UT) or eddy current testing (ECT).

2. Quality Control and Assurance

Monitor and maintain quality standards throughout the production process, ensuring that coiled steel products meet customer requirements and specifications.

- Review inspection data, identify trends, and recommend corrective actions to improve quality and minimize defects.

- Collaborate with production teams to implement quality control measures and enhance manufacturing processes.

- Maintain accurate records and documentation of inspection results, ensuring traceability and accountability.

3. Problem-Solving and Analysis

Troubleshoot and resolve issues related to coiled steel products, identifying root causes and recommending solutions.

- Analyze inspection data and identify patterns or anomalies that may indicate underlying problems.

- Conduct root cause analysis to determine the source of defects and develop preventative measures.

- Proactively monitor production processes and identify potential risks or areas for improvement.

4. Customer Support

Interact with customers and provide technical support, answering queries and resolving complaints.

- Respond to customer inquiries regarding product quality, specifications, and delivery status.

- Investigate customer complaints, conduct inspections, and provide feedback on the resolution.

- Build and maintain positive relationships with customers to foster long-term partnerships.

Interview Tips

Preparing effectively for a Coiled Coil Inspector interview can significantly enhance your chances of success. Here are some valuable tips to help you ace the interview:

1. Research the Company and Industry

Thoroughly research the company and the steel industry to gain a comprehensive understanding of their products, services, and market position. This knowledge will demonstrate your genuine interest and enthusiasm for the role.

2. Practice Inspection Techniques

Familiarize yourself with common inspection techniques used in the industry, such as dimensional measurements, surface quality assessments, and NDT methods. Practice using these techniques to enhance your confidence and demonstrate your proficiency during the interview.

3. Highlight Quality Control Experience

Emphasize your experience in quality control and assurance, showcasing your ability to maintain high standards, identify defects, and implement corrective actions. Quantify your accomplishments and provide specific examples of how you improved product quality.

4. Showcase Problem-Solving Skills

Highlight your problem-solving abilities and provide examples of how you have successfully identified and resolved issues related to coiled steel products. Explain your analytical approach, root cause analysis techniques, and recommendations for improvement.

5. Prepare for Technical Questions

Anticipate technical questions related to coiled steel properties, inspection methods, and industry standards. Study relevant materials, including industry codes and regulations, to demonstrate your knowledge and competence.

6. Rehearse Common Interview Questions

Prepare for common interview questions such as “Why are you interested in this role?” and “What are your strengths and weaknesses?” Practice answering these questions concisely and effectively, highlighting your relevant skills and experience.

7. Dress Professionally and Arrive on Time

First impressions matter, so dress professionally and arrive at the interview on time. This demonstrates respect for the interviewer and conveys your seriousness about the position.

8. Ask Informed Questions

During the interview, ask thoughtful questions that show your engagement and interest in the role. Inquire about the company’s quality control processes, inspection frequency, and opportunities for professional development.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Coiled Coil Inspector role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.