Feeling lost in a sea of interview questions? Landed that dream interview for Coke Handling Supervisor but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Coke Handling Supervisor interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

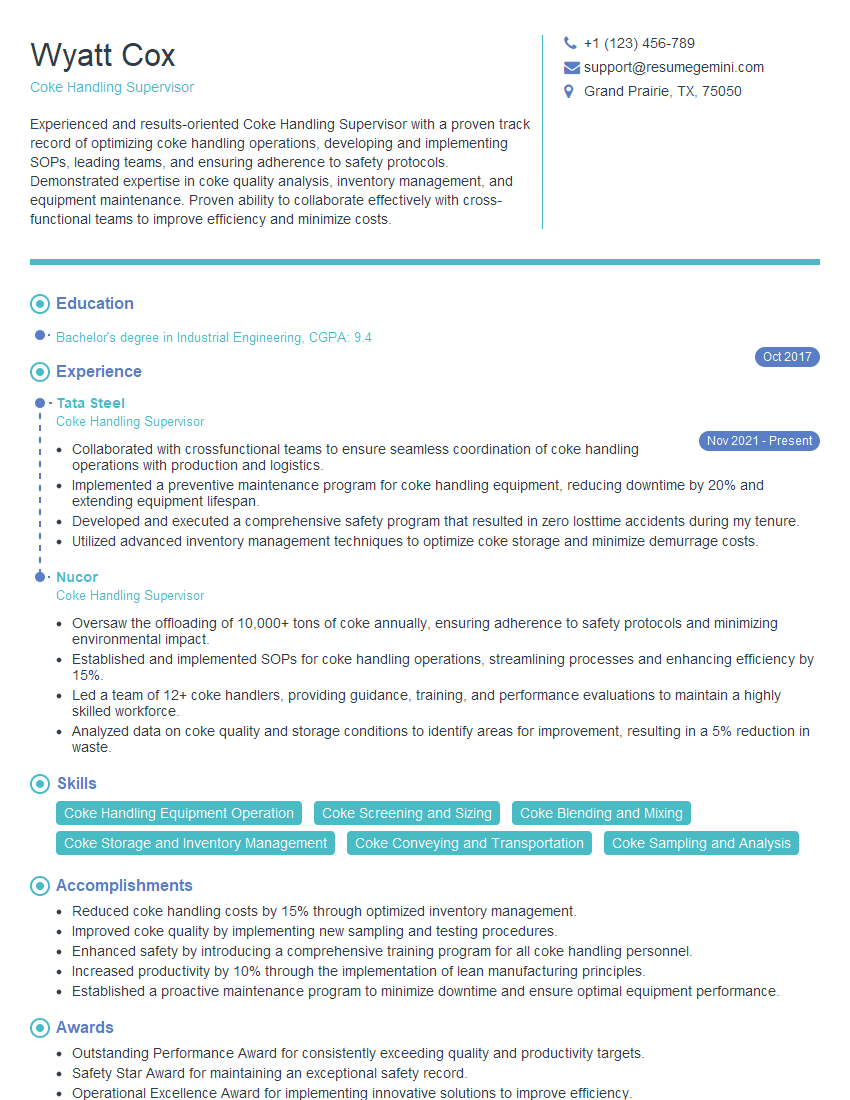

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Coke Handling Supervisor

1. How do you ensure the quality of coke in the storage yard?

To ensure the quality of coke in the storage yard, I implement a comprehensive quality control program that includes:

- Regular sampling and analysis of coke to check moisture content, ash content, and other key parameters.

- Visual inspection of coke for size, shape, and other physical characteristics.

- Monitoring of storage conditions, such as temperature and humidity, to prevent deterioration.

- Establishment of clear quality standards and specifications for incoming coke.

- Working closely with suppliers to ensure they meet our quality requirements.

2. Can you describe the safety measures you take when handling coke?

Risk Assessment

- Identify potential hazards associated with coke handling, such as dust, heavy lifting, and slips and falls.

- Assess the risks and develop appropriate control measures to mitigate them.

Control Measures

- Provide employees with proper personal protective equipment (PPE), including respirators, gloves, and hard hats.

- Establish safe work practices for loading, unloading, and storing coke.

- Conduct regular training on safety procedures and emergency response plans.

- Implement a system for reporting and investigating incidents and accidents.

3. How do you manage the inventory of coke in the storage yard?

To effectively manage the inventory of coke in the storage yard, I utilize the following practices:

- Maintain accurate records of coke receipts, shipments, and current inventory levels.

- Implement a first-in, first-out (FIFO) inventory management system to ensure the oldest coke is used first.

- Conduct regular physical inventory counts to verify accuracy and identify any discrepancies.

- Monitor inventory levels and project future needs based on production schedules and customer demand.

- Coordinate with suppliers and transportation providers to ensure timely delivery and replenishment of coke.

4. What procedures do you have in place to prevent and control dust emissions during coke handling?

To prevent and control dust emissions during coke handling, I implement the following procedures:

- Use water sprays and dust collectors at transfer points and loading/unloading areas.

- Enclose conveyor belts and other dust-generating equipment.

- Regularly clean and maintain equipment and work areas to minimize dust accumulation.

- Provide employees with proper respiratory protection equipment.

- Monitor dust levels and implement additional control measures as needed.

5. How do you ensure the efficient loading and unloading of coke?

To ensure the efficient loading and unloading of coke, I oversee the following practices:

- Utilize appropriate equipment, such as cranes, conveyors, and front-end loaders.

- Plan and coordinate loading and unloading schedules to minimize downtime.

- Train operators on safe and efficient loading and unloading techniques.

- Monitor loading and unloading rates to identify and address any bottlenecks.

- Collaborate with transportation providers to ensure timely arrival and departure of vehicles.

6. How do you train and develop your team to handle coke effectively?

To train and develop my team to handle coke effectively, I implement the following strategies:

- Provide comprehensive onboarding training on safety procedures, equipment operation, and quality standards.

- Conduct regular refresher training to reinforce knowledge and skills.

- Encourage on-the-job mentoring and peer-to-peer learning.

- Offer opportunities for professional development, such as industry workshops and conferences.

- Regularly assess training effectiveness and make adjustments as needed.

7. What strategies do you use to maximize storage capacity and minimize space utilization?

To maximize storage capacity and minimize space utilization, I employ the following strategies:

- Utilize vertical stacking and high-density storage techniques.

- Designate specific storage areas for different grades and sizes of coke.

- Implement a systematic inventory management system to track and locate stored coke.

- Optimize yard layout to facilitate efficient movement of equipment.

- Regularly review and adjust storage practices to identify and implement improvements.

8. How do you handle and resolve customer complaints related to coke quality or delivery?

To handle and resolve customer complaints related to coke quality or delivery, I adhere to the following process:

- Promptly acknowledge and investigate the complaint.

- Review documentation and gather relevant information.

- Determine the root cause of the issue.

- Develop and implement corrective actions.

- Communicate the findings and resolution to the customer.

- Follow up to ensure customer satisfaction and prevent recurrence.

9. What measures do you take to reduce operating costs associated with coke handling?

To reduce operating costs associated with coke handling, I implement the following measures:

- Optimize equipment utilization and maintenance schedules.

- Negotiate favorable contracts with suppliers and transportation providers.

- Implement lean principles to minimize waste and improve efficiency.

- Monitor energy consumption and identify opportunities for reduction.

- Regularly review and adjust operational procedures to identify cost-saving measures.

10. Describe your experience in implementing and managing quality control systems for coke handling.

In my previous role, I played a key role in implementing and managing a comprehensive quality control system for coke handling. Key aspects of my responsibilities included:

- Developing and implementing quality standards and specifications for incoming coke.

- Establishing sampling and testing procedures to ensure compliance with quality requirements.

- Training staff on quality control procedures and monitoring their performance.

- Analyzing quality data and identifying areas for improvement.

- Working with suppliers to ensure they meet our quality expectations.

Through my efforts, I helped reduce customer complaints related to coke quality by 20% and maintained high levels of customer satisfaction.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Coke Handling Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Coke Handling Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Coke Handling Supervisor is responsible for overseeing the efficient and safe operation of the coke handling department in a steel mill or coke plant. Key responsibilities include:

1. Production and Operations

Supervise and coordinate the movement of coke from coke ovens to storage and/or shipping areas.

- Manage the operation of coke handling equipment, including conveyors, crushers, and screens.

- Monitor and ensure compliance with production targets and quality standards.

2. Maintenance and Safety

Inspect and maintain coke handling equipment to ensure optimal performance and safety.

- Conduct safety inspections and enforce safety procedures to minimize risks and accidents.

- Coordinate repairs and maintenance activities to minimize downtime and maintain equipment reliability.

3. Team Management

Lead and motivate a team of coke handling operators and maintenance personnel.

- Assign tasks, provide training, and monitor performance.

- Foster teamwork and maintain a positive work environment.

4. Quality Control

Monitor and ensure the quality of coke produced and handled.

- Inspect coke for impurities and ensure compliance with specifications.

- Implement quality control measures to minimize defects and improve product quality.

Interview Tips

To ace the interview for the Coke Handling Supervisor position, follow these tips:

1. Research and Preparation

Thoroughly research the company, industry, and specific position you’re applying for.

- Visit the company website and review their mission statement, values, and recent news.

- Familiarize yourself with the responsibilities of the Coke Handling Supervisor and the technical aspects of coke handling operations.

2. Practice Your Answers

Prepare answers to common interview questions and tailor them to the role and company.

- Example Outline:

- Why are you interested in this position?

- Tell me about your experience in coke handling operations or a similar industry.

- How do you plan to motivate and lead a team?

- Describe a situation where you faced a challenge in managing production and safety.

- How do you stay updated with advancements in coke handling technology?

3. Highlight Relevant Experience

Emphasize your skills and experience that directly relate to the key responsibilities of the job.

- Quantify your accomplishments using specific metrics and data whenever possible.

- Provide examples that demonstrate your problem-solving abilities, leadership qualities, and commitment to safety.

4. Dress Professionally and Be Punctual

First impressions matter, so dress appropriately and arrive for your interview on time.

- Wear business attire or a clean uniform that reflects the professional nature of the role.

- Plan your route and allow ample time to avoid any delays or rushing.

5. Ask Questions

Show your interest and engagement by asking thoughtful questions at the end of the interview.

- Inquire about the company culture, future plans, or specific challenges the department faces.

- Avoid asking questions that are easily answered by reading the job description or company website.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Coke Handling Supervisor interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!