Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Coke Oven Mason position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

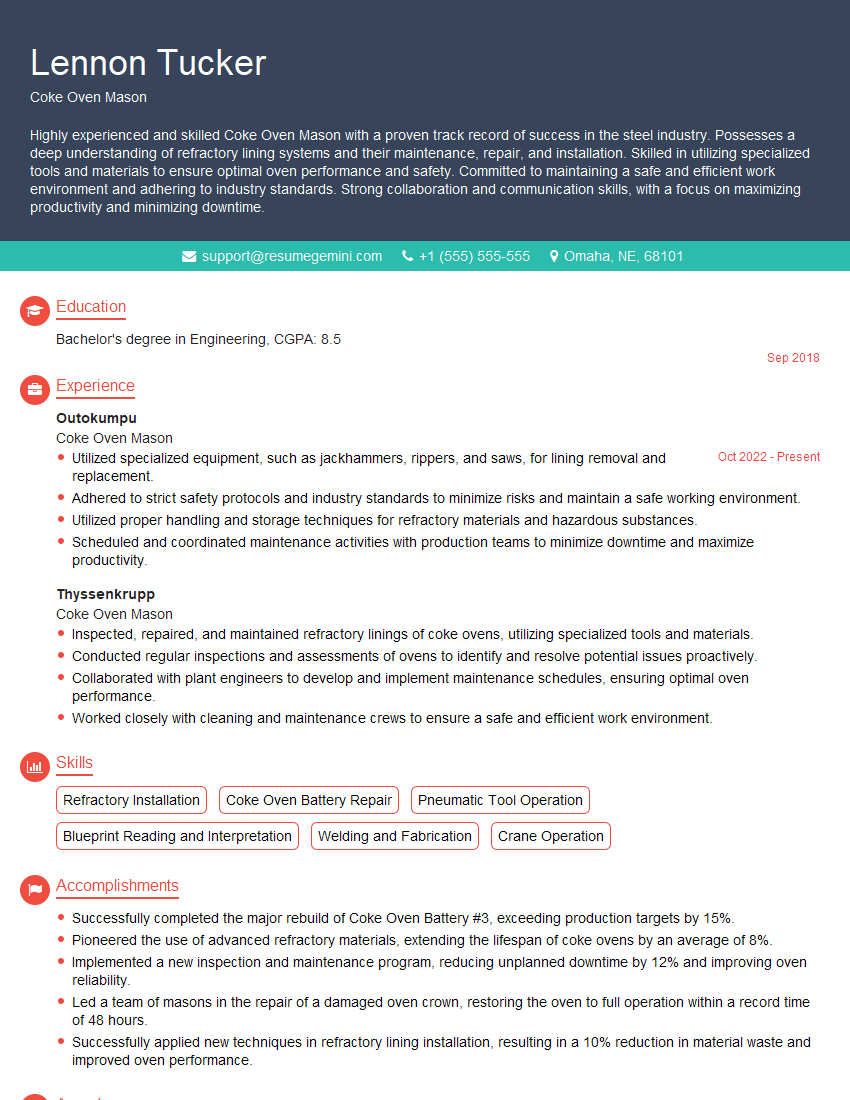

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Coke Oven Mason

1. What are the main responsibilities of a Coke Oven Mason?

- Inspect, repair, and maintain coke ovens and related equipment

- Plan and schedule maintenance work

- Troubleshoot and resolve mechanical and electrical problems

- Work safely and follow all safety procedures

- Train and supervise junior masons

2. What are the different types of coke ovens?

Beehive Ovens

- Earliest and simplest type of coke oven

- Dome-shaped and made of firebrick or silica brick

- Charge is loaded through an opening at the top

- Coke is pushed out from the bottom once it has been cooked

By-Product Ovens

- More modern and efficient than beehive ovens

- Produce valuable by-products such as coal tar, coal gas, and ammonium sulfate

- Charge is loaded through the top and coke is pushed out from the bottom

3. What are the key properties of a good quality coke?

- High carbon content (85-95%)

- Low ash content (less than 10%)

- Low sulfur content (less than 1%)

- High mechanical strength

- Good porosity

4. What are the main causes of coke oven failures?

- Thermal stress

- Mechanical stress

- Chemical attack

- Corrosion

- Wear and tear

5. What is the role of refractory materials in coke ovens?

- Protect the oven walls from high temperatures

- Provide insulation to reduce heat loss

- Resist chemical attack from the coke oven gases

6. What are the different types of refractories used in coke ovens?

- Fireclay brick

- Silica brick

- Magnesite brick

- Chrome brick

- Carbon brick

7. What are the main steps involved in repairing a coke oven wall?

- Remove the damaged bricks

- Prepare the surface of the oven wall

- Install new bricks

- Grout the joints between the bricks

- Dry out the oven wall

8. What are the safety precautions that must be taken when working on a coke oven?

- Wear appropriate personal protective equipment (PPE)

- Identify and control hazards

- Follow safe work procedures

- Be aware of the potential for hazards such as heat, dust, and gases

- Use proper tools and equipment

9. What are the latest trends in coke oven technology?

- Use of higher quality refractories

- Development of new coke oven designs

- Implementation of automated control systems

- Increased use of by-product recovery systems

- Focus on environmental sustainability

10. What are the career advancement opportunities for Coke Oven Masons?

- Lead Mason

- Mason Foreman

- Supervisor

- Manager

- Consultant

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Coke Oven Mason.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Coke Oven Mason‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Coke Oven Masons perform a variety of tasks to ensure the proper construction, maintenance, and repair of coke ovens.

1. Construct and Install Coke Ovens

They build, install, and repair coke ovens, which are used to convert coal into coke. Coke is an essential component in the production of iron and steel.

- Study blueprints and specifications to determine the materials and methods required for the construction or repair of coke ovens.

- Install and repair oven walls, roofs, and other components.

- Inspect and test ovens to ensure they are properly constructed and functioning.

2. Maintain and Repair Coke Ovens

The coke ovens need regular maintenance and repair. They inspect the ovens for any damage or wear and tear, and make necessary repairs.

- Inspect and identify any damaged or worn parts.

- Repair or replace damaged parts, such as bricks, tiles, and seals.

- Clean and clear any debris or blockages from the ovens.

3. Perform Preventative Maintenance

To prevent any major breakdowns or accidents, they also perform preventative maintenance on the ovens. This includes inspecting the ovens for any potential problems and making necessary repairs or adjustments.

- Inspect ovens regularly for signs of wear or damage.

- Perform routine maintenance tasks, such as lubricating moving parts and cleaning or replacing filters.

- Identify and resolve potential problems before they become major issues.

4. Work in a Team

Coke Oven Masons often work in a team, particularly when constructing or repairing large ovens. They are able to communicate effectively and collaborate with their team members.

- Work with other masons and construction workers to complete projects on time and to specifications.

- Follow safety procedures and regulations.

- Maintain a clean and safe work area.

Interview Tips

Preparing for an interview can be daunting but with the right approach and practice, you can increase your chances of success.

1. Research the Company and Position

Before the interview, research the company and the specific position you are applying for.

- Visit the company’s website and social media pages to learn about their history, culture, and values.

- Review the job description and identify the key responsibilities and qualifications.

2. Practice Answering Common Interview Questions

There are some common interview questions that you can prepare for in advance.

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- Why should we hire you?

3. Prepare Questions to Ask the Interviewer

Asking thoughtful questions at the end of an interview shows that you are engaged and interested in the position.

- What are the biggest challenges facing the company right now?

- What is the company culture like?

- What is the next step in the hiring process?

4. Dress Professionally and Arrive on Time

First impressions matter, so make sure to dress professionally and arrive on time for your interview.

- Wear clean, pressed clothes that are appropriate for a business setting.

- Be punctual and arrive at the interview location a few minutes early.

Next Step:

Now that you’re armed with the knowledge of Coke Oven Mason interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Coke Oven Mason positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini