Feeling lost in a sea of interview questions? Landed that dream interview for Coke Oven Patcher but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Coke Oven Patcher interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

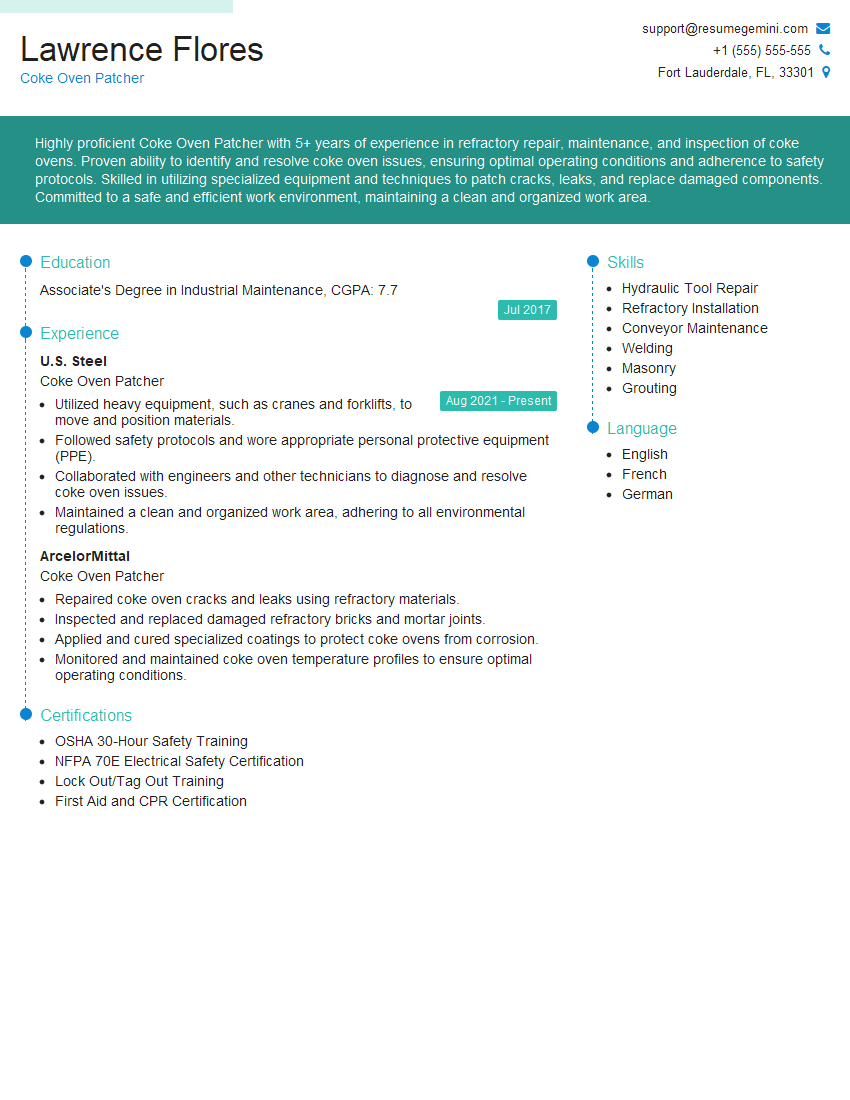

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Coke Oven Patcher

1. Describe the steps involved in patching a coke oven.

The steps involved in patching a coke oven are as follows:

- Inspect the oven for damage and mark the areas that need to be patched.

- Prepare the patch material by mixing the appropriate ingredients according to the manufacturer’s instructions.

- Apply the patch material to the damaged area using a trowel or other tool.

- Smooth out the patch material and allow it to cure.

- Inspect the patch for any defects and make any necessary repairs.

2. What are the different types of patch materials used for coke ovens?

Refractory materials

- Fireclay

- High-alumina brick

- Magnesite-chrome brick

Non-refractory materials

- Epoxies

- Polymers

- Metals

3. What are the factors that affect the choice of patch material?

- The type of damage

- The location of the damage

- The operating temperature of the oven

- The availability of materials

4. What are the safety precautions that must be taken when patching a coke oven?

- Wear appropriate personal protective equipment, including a hard hat, safety glasses, gloves, and a respirator.

- Ventilate the work area to prevent the buildup of harmful gases.

- Use proper tools and equipment to avoid injury.

5. What are the potential hazards associated with patching a coke oven?

- Exposure to harmful gases, such as carbon monoxide and hydrogen sulfide

- Burns from hot surfaces

- Injuries from falling objects or tripping

6. What is the importance of proper patching?

- To extend the life of the coke oven

- To prevent further damage to the oven

- To ensure the safe operation of the oven

7. How do you determine the extent of damage to a coke oven?

- Visually inspect the oven for cracks, spalling, or other damage.

- Use a hammer to tap the oven and listen for hollow sounds, which may indicate internal damage.

- Use a borescope to inspect the inside of the oven for damage that is not visible from the outside.

8. What are the different techniques used to patch a coke oven?

- Gunite

- Shotcrete

- Ramming mass

9. What are the advantages and disadvantages of each patching technique?

Gunite

- Advantages: Can patch large areas;

- Relatively easy to apply

- Disadvantages: Can be expensive;

- Not as durable as other patching techniques

Shotcrete

- Advantages: Durable;

- Can patch large areas

- Disadvantages: Can be difficult to apply;

- Requires specialized equipment

Ramming mass

- Advantages: Durable;

- Relatively easy to apply

- Disadvantages: Can be expensive;

- Not as versatile as other patching techniques

10. What is the best patching technique for a particular coke oven?

- The best patching technique for a particular coke oven will depend on the extent of damage, the location of the damage, and the operating temperature of the oven.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Coke Oven Patcher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Coke Oven Patcher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Coke Oven Patchers are responsible for maintaining the coke ovens used in the production of coke, a key ingredient in steelmaking. Their primary duties include:

1. Patching and Repairing Coke Ovens

Patchers are responsible for inspecting coke ovens for cracks, leaks, and other damage, and performing the necessary repairs to ensure the ovens are safe and operational. This may involve using refractory materials to patch cracks, replacing damaged bricks, or installing new oven components.

- Inspect coke ovens for damage and identify areas in need of repair.

- Mix and apply refractory materials to patch cracks and holes.

- Replace damaged bricks and other oven components.

- Monitor the condition of ovens and make necessary repairs to prevent further damage.

2. Cleaning and Maintaining Coke Ovens

Patchers also perform regular cleaning and maintenance tasks to keep the coke ovens in good condition. This may include removing debris from the ovens, cleaning out gas lines, and lubricating moving parts.

- Remove debris and buildup from coke ovens.

- Clean gas lines and other oven components.

- Lubricate moving parts to ensure smooth operation.

- Maintain records of cleaning and maintenance activities.

3. Monitor Oven Operations

Patchers are responsible for monitoring the operation of coke ovens to ensure they are functioning safely and efficiently. This may involve checking temperatures, pressures, and other operating parameters, and taking corrective action as needed.

- Monitor oven temperatures, pressures, and other operating parameters.

- Identify and correct any operational problems.

- Maintain records of oven operations and maintenance activities.

- Report any unusual or potentially hazardous conditions to supervisors.

4. Safety and Environmental Compliance

Patchers must adhere to strict safety and environmental regulations when performing their duties. This may include wearing appropriate protective gear, following proper handling procedures for hazardous materials, and disposing of waste materials in accordance with environmental regulations.

- Wear appropriate personal protective equipment (PPE) when working on ovens.

- Follow proper handling procedures for hazardous materials.

- Dispose of waste materials in accordance with environmental regulations.

- Maintain a safe and clean work environment.

Interview Tips

To ace an interview for a Coke Oven Patcher position, it’s important to demonstrate your technical skills, safety awareness, and commitment to teamwork.

1. Research the Company and Position

Before the interview, take the time to research the company you’re applying to and the specific Coke Oven Patcher position. This will show the interviewer that you’re genuinely interested in the role and the company’s operations.

- Visit the company’s website to learn about their history, products, and services.

- Read industry news and articles to stay up-to-date on the latest developments in coke oven maintenance.

- Prepare questions to ask the interviewer about the company and the position.

2. Highlight Your Technical Skills

The interviewer will want to know that you have the technical skills required to perform the job effectively. Be prepared to discuss your experience with:

- Patching and repairing coke ovens.

- Cleaning and maintaining coke ovens.

- Monitoring oven operations.

- Adhering to safety and environmental regulations.

3. Emphasize Your Safety Awareness

Safety is paramount in the coke oven industry. Highlight your understanding of the safety risks associated with working on coke ovens and your commitment to following all safety protocols.

- Describe your experience with wearing appropriate PPE and following proper handling procedures for hazardous materials.

- Explain how you would respond to a safety emergency.

- Discuss your commitment to maintaining a clean and safe work environment.

4. Demonstrate Your Teamwork Skills

Coke Oven Patchers often work as part of a team to maintain the coke ovens. Be prepared to discuss your experience working in a team environment and your ability to contribute to the team’s success.

- Describe your experience working on team projects.

- Explain how you would handle a disagreement with a team member.

- Discuss your commitment to helping your team achieve its goals.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Coke Oven Patcher, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Coke Oven Patcher positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.