Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Coke Production Heater position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

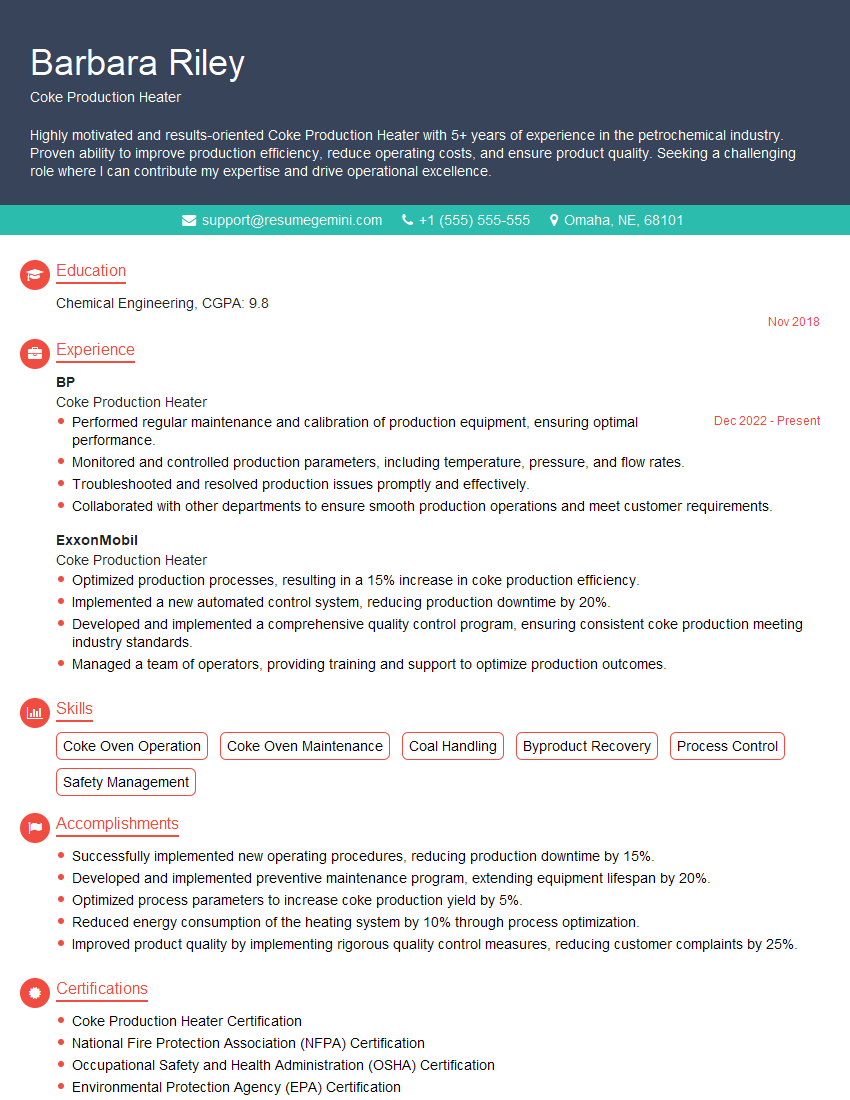

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Coke Production Heater

1. Explain the process of coke production in a coke oven?

- Coal is heated in the absence of oxygen to drive off volatile matter, leaving behind a porous carbon residue called coke.

- The coal is first crushed and sized to ensure uniform heating.

- The coal is then charged into coke ovens, which are heated to a temperature of about 1000°C.

- The heating process drives off the volatile matter, which is collected and used as a fuel.

- The coke that remains is cooled and used in a variety of industrial applications, such as steelmaking and foundry work.

2. What are the different types of coke ovens?

- There are two main types of coke ovens: beehive ovens and byproduct ovens.

- Beehive ovens are the traditional type of coke oven, and they are still used in some parts of the world.

- Beehive ovens are inefficient and produce a lot of pollution, so they are being phased out in favor of byproduct ovens.

- Byproduct ovens are more efficient and produce less pollution than beehive ovens.

- Byproduct ovens also capture the volatile matter that is driven off during the coking process, and this can be used as a fuel or a chemical feedstock.

3. What are the key factors that affect the quality of coke?

- The quality of coke is determined by a number of factors, including the type of coal used, the coking time, and the temperature of the coking process.

- The type of coal used has a significant impact on the quality of the coke.

- Coking time is also important, as a longer coking time produces a stronger and more dense coke.

- The temperature of the coking process also affects the quality of the coke, as a higher temperature produces a more porous and reactive coke.

4. What are the different uses of coke?

- Coke is used in a variety of industrial applications, including steelmaking, foundry work, and the production of chemicals.

- In steelmaking, coke is used as a fuel and a reducing agent.

- In foundry work, coke is used as a fuel and a carbon source.

- In the production of chemicals, coke is used as a feedstock for the production of a variety of chemicals, including ammonia, benzene, and toluene.

5. What are the environmental concerns associated with coke production?

- Coke production can have a negative impact on the environment, as it produces a number of air pollutants, including particulate matter, sulfur dioxide, and nitrogen oxides.

- Coke production also produces wastewater, which can contain a variety of pollutants, including phenols, ammonia, and cyanide.

- In addition, coke production can generate solid waste, which can include coke breeze, spent refractory bricks, and filter cake.

6. What are the different ways to mitigate the environmental impacts of coke production?

- There are a number of ways to mitigate the environmental impacts of coke production, including:

- Using cleaner coal

- Improving the efficiency of the coking process

- Installing pollution control equipment

- Recycling waste materials

7. What are the challenges facing the coke production industry?

- The coke production industry is facing a number of challenges, including:

- Increasing environmental regulations

- Rising energy costs

- Competition from other fuels

- The decline of the steel industry

8. What are the opportunities for the coke production industry?

- The coke production industry has a number of opportunities for growth, including:

- The development of new technologies

- The growth of the chemical industry

- The expansion of the steel industry in developing countries

9. What are the key trends in the coke production industry?

- The key trends in the coke production industry include:

- The increasing use of cleaner coal

- The adoption of more efficient coking processes

- The installation of pollution control equipment

- The recycling of waste materials

10. What are the future prospects for the coke production industry?

- The future prospects for the coke production industry are mixed.

- On the one hand, the industry is facing a number of challenges, including increasing environmental regulations, rising energy costs, and competition from other fuels.

- On the other hand, the industry has a number of opportunities for growth, including the development of new technologies, the growth of the chemical industry, and the expansion of the steel industry in developing countries.

- Overall, the future prospects for the coke production industry are uncertain.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Coke Production Heater.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Coke Production Heater‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Coke Production Heaters are responsible for the operation and maintenance of coke production equipment, ensuring the efficient and safe production of coke. Their key responsibilities include:

1. Equipment Operation and Maintenance

Operate and maintain coke production equipment, including ovens, conveyors, and quenching towers.

- Monitor equipment performance and make necessary adjustments to optimize production.

- Perform routine maintenance and repairs to keep equipment in good working order.

2. Production Monitoring and Control

Monitor and control the coke production process to ensure quality and efficiency.

- Track production rates, temperatures, and other process parameters.

- Identify and resolve production issues to minimize downtime and maintain production schedules.

3. Quality Assurance

Ensure the quality of coke produced by performing regular inspections and tests.

- Inspect coke for defects, such as cracks or impurities.

- Conduct chemical and physical tests to verify coke quality meets specifications.

4. Safety and Environmental Compliance

Maintain a safe and environmentally compliant work environment.

- Follow safety protocols and procedures to prevent accidents and injuries.

- Monitor and control emissions to comply with environmental regulations.

Interview Tips

To ace the interview for a Coke Production Heater position, follow these tips:

1. Research the Company and Industry

Familiarize yourself with the company’s history, products, and industry trends.

- This shows that you’re interested in the company and have taken the initiative to learn more about their operations.

2. Practice Answering Common Interview Questions

Prepare for common interview questions related to your skills and experience.

- Rehearse your answers to questions about your technical expertise, safety procedures, and problem-solving abilities.

3. Showcase Your Technical Abilities

Highlight your knowledge of coke production processes and equipment.

- Describe your experience in operating and maintaining coke ovens, conveyors, and quenching towers.

- Explain your understanding of coke production parameters and quality control techniques.

4. Emphasize Safety and Environmental Compliance

Demonstrate your commitment to safety and environmental regulations.

- Share examples of your experience in following safety protocols and preventing accidents.

- Explain your knowledge of environmental regulations and your role in ensuring compliance.

5. Prepare Questions to Ask the Interviewer

Asking thoughtful questions shows your interest and engagement in the interview.

- For example, ask about the company’s production goals, safety initiatives, or opportunities for professional development.

Next Step:

Now that you’re armed with the knowledge of Coke Production Heater interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Coke Production Heater positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini