Feeling lost in a sea of interview questions? Landed that dream interview for Cold-Press Loader but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Cold-Press Loader interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

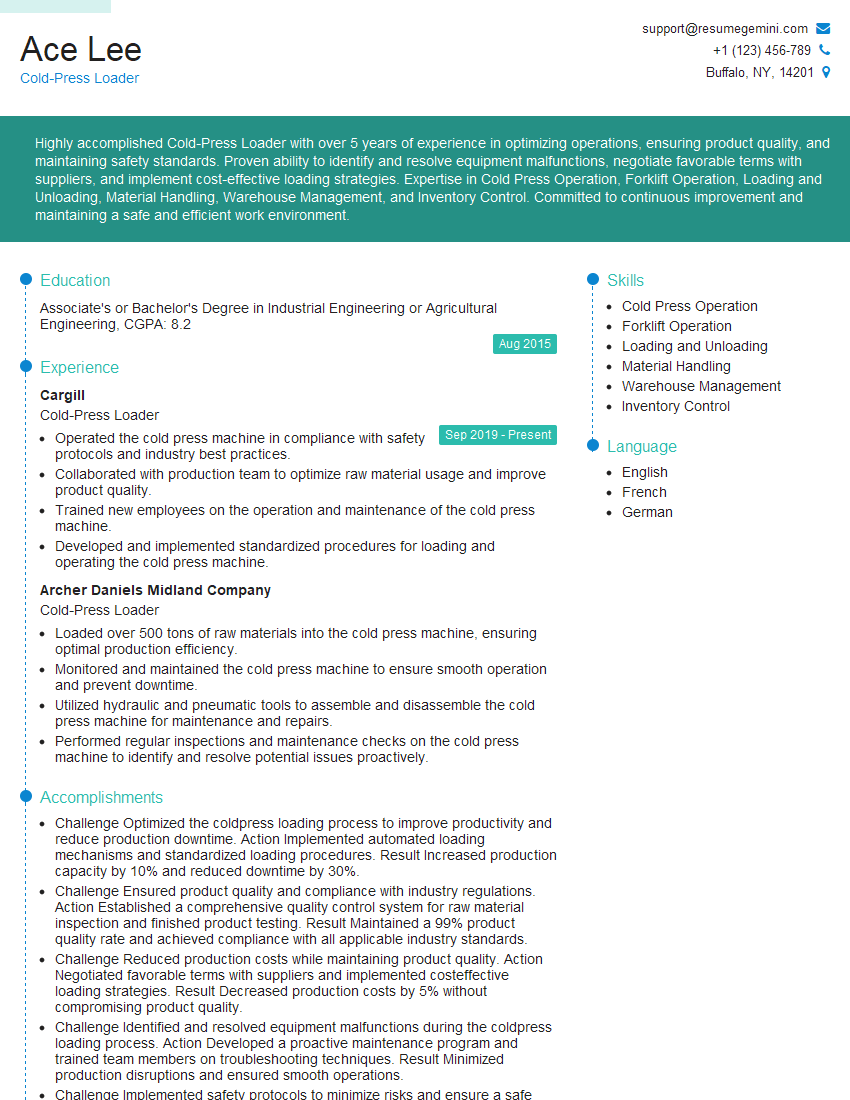

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cold-Press Loader

1. What are the responsibilities of a Cold-Press Loader?

The primary responsibilities of a Cold-Press Loader include:

- Loading and unloading raw materials into and out of the cold press machine.

- Monitoring the machine’s operation to ensure that it is running smoothly.

- Troubleshooting and resolving any issues that may arise during the pressing process.

- Maintaining the machine and work area to ensure that they are clean and safe.

- Following all safety protocols to prevent accidents.

2. What are the different types of cold press machines?

Hydraulic Cold Press Machine

- Generates pressure through hydraulic fluid

- Capable of producing high pressures

Mechanical Cold Press Machine

- Uses a mechanical lever or screw to generate pressure

- Produces lower pressure than hydraulic machines

3. What are the factors that affect the efficiency of a cold press machine?

The efficiency of a cold press machine is influenced by the following factors:

- Machine capacity

- Pressure applied

- Temperature of the materials being pressed

- Size and shape of the materials being pressed

- Maintenance and calibration of the machine.

4. What are the safety precautions that should be taken when operating a cold press machine?

To ensure safe operation of a cold press machine it’s important to:

- Wear appropriate safety gear.

- Follow all operating instructions.

- Never operate the machine if it is not in good working order.

- Be aware of the machine’s limitations.

- Report any problems to a supervisor immediately.

5. What are some common problems that can occur with cold press machines?

Some common problems that can occur with cold press machines include:

- Leaking hydraulic fluid

- Malfunctioning pressure gauge

- Overheating motor

- Clogged filter

- Damaged ram.

6. What are your troubleshooting techniques for resolving issues with cold press machines?

To effectively troubleshoot issues, I follow a systematic approach that includes:

- Identifying the problem

- Checking for any loose connections or leaks

- Inspecting the machine for any damaged components

- Consulting the machine’s manual for troubleshooting tips

- Contacting a qualified technician if the problem persists.

7. How do you maintain a cold press machine to ensure optimal performance?

To maintain optimal performance of a cold press machine, I regularly perform the following tasks:

- Cleaning the machine

- Lubricating moving parts

- Checking and replacing worn parts

- Calibrating the machine

- Following the manufacturer’s maintenance schedule.

8. What is the difference between cold pressing and hot pressing?

- Cold pressing: Extracts oil from materials at low temperatures, preserving nutrients and flavors.

- Hot pressing: Uses heat to extract oil, resulting in a higher yield but potentially compromising nutritional value.

9. What are the applications of cold-pressed oil?

- Food industry: Culinary oils, salad dressings, and baking

- Cosmetics: Skin and hair care products

- Pharmaceuticals: Drug formulations and supplements

10. How do you ensure the quality of cold-pressed oil?

- Sourcing high-quality raw materials

- Maintaining optimal pressing conditions

- Conducting regular quality control checks

- Storing oil properly to preserve its freshness

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cold-Press Loader.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cold-Press Loader‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Cold-Press Loaders are responsible for operating and maintaining presses that cold-press rubber or plastic materials into specific shapes or forms. Their primary duties include:

1. Loading and Unloading Presses

Loading raw materials, such as rubber or plastic compounds, into presses and ensuring proper alignment and positioning.

2. Machine Operation

Operating cold-press machines according to established procedures and safety guidelines.

3. Quality Control

Monitoring the pressing process and ensuring the quality of finished products, including dimensions, surface finish, and structural integrity.

4. Maintenance and Troubleshooting

Performing routine maintenance on presses and troubleshooting any technical issues that arise during operation.

Interview Tips

To prepare for an interview as a Cold-Press Loader, it is important to:

1. Research the Company and Position

Familiarize yourself with the company’s background, values, and the specific requirements of the Cold-Press Loader position.

- Visit the company’s website and read about their mission, products, and services.

- Review the job description thoroughly and identify the key skills and responsibilities required.

2. Highlight Relevant Skills and Experience

Emphasize your previous experience operating cold-press machinery and handling rubber or plastic materials.

- Quantify your accomplishments by using specific examples and metrics.

- Demonstrate your knowledge of quality control procedures and safety protocols.

3. Prepare for Technical Questions

Be prepared to answer questions about the operation and maintenance of cold-press machines.

- Review common troubleshooting techniques and safety procedures.

- Practice explaining complex technical concepts in clear and concise language.

4. Express Enthusiasm and Motivation

Demonstrate your passion for the industry and your eagerness to learn and grow within the role.

- Share your interest in the company’s products or services.

- Explain how your skills and experience align with the company’s goals.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Cold-Press Loader interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.