Are you gearing up for an interview for a Cold Rolling Supervisor position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Cold Rolling Supervisor and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

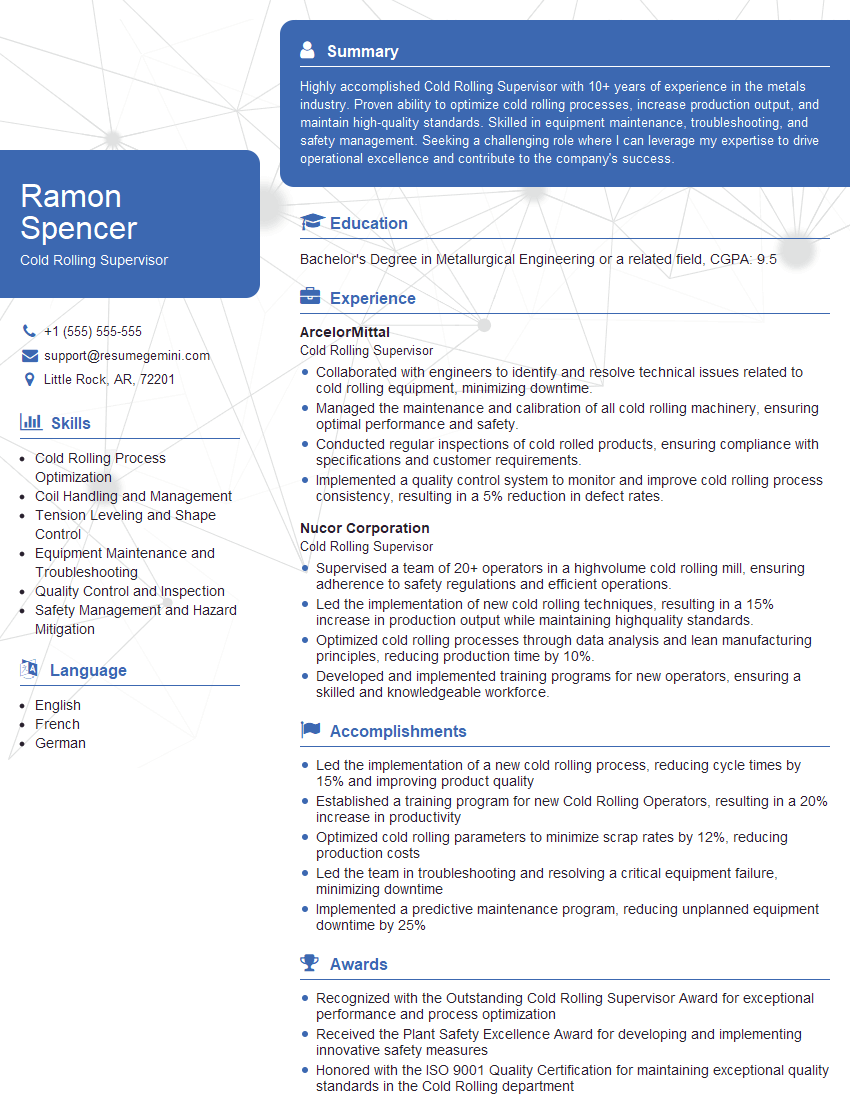

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cold Rolling Supervisor

1. Can you elaborate on the typical responsibilities of a Cold Rolling Supervisor?

As a Cold Rolling Supervisor, my primary responsibilities would include:

- Overseeing and managing cold rolling operations to ensure efficient production and high-quality output.

- Coordinating with operators and technicians to optimize processes, address production issues, and maintain equipment.

- Monitoring production data, identifying bottlenecks, and implementing improvement initiatives to enhance efficiency.

2. Describe the key performance indicators you track to assess the effectiveness of cold rolling operations.

Throughput and Productivity

- Tons of material processed per hour

- Overall equipment effectiveness (OEE)

Quality

- Surface finish and dimensional accuracy

- Coil properties (e.g., thickness, width, hardness)

Safety

- Incident rates and near misses

- Compliance with safety protocols

3. What are the common challenges you have faced in managing a cold rolling mill? How did you address them?

- Production bottlenecks: Implemented lean manufacturing principles, analyzed production data, and made process adjustments to improve flow.

- Quality issues: Conducted root cause analysis, identified equipment issues, and coordinated with maintenance to resolve the problems.

- Safety concerns: Implemented safety protocols, provided training to operators, and enforced compliance to minimize risks.

4. Explain the importance of proper maintenance and calibration of cold rolling equipment.

- Ensures optimal performance: Well-maintained equipment operates efficiently, reducing downtime and maximizing production.

- Prevents defects: Calibrated equipment produces consistent and high-quality products, minimizing scrap and rework.

- Enhances safety: Proper maintenance ensures equipment is safe to operate, reducing the risk of accidents.

5. What techniques do you use to improve the efficiency of cold rolling operations?

- Six Sigma: Identify and eliminate waste, streamlining processes and reducing production time.

- Value Stream Mapping: Analyze production flow, identify bottlenecks, and make changes to enhance efficiency.

- Equipment Optimization: Analyze equipment performance data, identify areas for improvement, and implement adjustments to maximize productivity.

6. How do you ensure the safety of your team while working in a cold rolling environment?

- Training and Education: Provide comprehensive training on safety protocols, equipment operation, and emergency procedures.

- Hazard Identification: Regularly assess work areas for potential hazards and implement measures to mitigate risks.

- Personal Protective Equipment: Enforce the use of appropriate PPE (e.g., gloves, earplugs, safety glasses) to protect operators.

7. How do you stay abreast of the latest advancements in cold rolling technology?

- Industry Conferences and Webinars: Attend industry events to learn about new technologies and best practices.

- Vendor Communication: Collaborate with equipment manufacturers to gain insights into the latest developments and potential improvements.

- Research and Development: Conduct research and explore innovative solutions to enhance cold rolling processes.

8. Describe your experience in troubleshooting and resolving production issues.

- Identify Root Cause: Utilize problem-solving techniques to identify the underlying cause of production issues.

- Develop Solutions: Collaborate with engineers, technicians, and operators to develop effective solutions to address the problems.

- Implement and Monitor: Implement the solutions, monitor their effectiveness, and make adjustments as needed to ensure sustained improvement.

9. How do you optimize the use of resources, such as manpower and materials, in a cold rolling operation?

- Workforce Planning: Plan and schedule workforce to ensure optimal coverage and minimize overtime.

- Materials Management: Monitor raw material inventory, optimize purchasing, and reduce waste to control costs.

- Equipment Utilization: Analyze equipment usage, identify idle time, and implement strategies to increase productivity.

10. Describe your approach to continuous improvement in a cold rolling mill.

- Performance Monitoring: Establish key performance indicators and regularly track progress to identify areas for improvement.

- Employee Involvement: Encourage employee feedback, suggestions, and participation in improvement initiatives.

- Data Analysis: Utilize data analytics to identify trends, analyze performance, and make informed decisions for optimization.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cold Rolling Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cold Rolling Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Cold Rolling Supervisor is responsible for overseeing the cold rolling process, ensuring that the product meets the required specifications and quality standards. They work closely with the production team to coordinate and monitor all aspects of the cold rolling operation.

1. Production Planning and Scheduling

The supervisor plans and schedules production to meet customer orders and maintain efficient operations. They develop production schedules, allocate resources, and coordinate with other departments to ensure a smooth production flow.

- Plan and schedule production to meet customer orders.

- Allocate resources and coordinate with other departments to ensure a smooth production flow.

2. Quality Control and Assurance

The supervisor is responsible for ensuring the quality of the cold rolled product by monitoring and inspecting the production process, identifying any defects, and taking corrective action to prevent future defects.

- Monitor and inspect the production process to identify any defects.

- Take corrective action to prevent future defects.

3. Maintenance and Repair

The supervisor is responsible for maintaining and repairing cold rolling equipment to ensure efficient operations and prevent breakdowns. They work with the maintenance team to schedule and oversee repairs, troubleshoot problems, and ensure that equipment is operating at peak efficiency.

- Schedule and oversee repairs of cold rolling equipment.

- Troubleshoot problems and ensure that equipment is operating at peak efficiency.

4. Team Management and Development

The supervisor is responsible for leading, motivating, and developing the cold rolling team. They provide training, guidance, and support to ensure that the team is working effectively and efficiently.

- Lead, motivate, and develop the cold rolling team.

- Provide training, guidance, and support to ensure that the team is working effectively and efficiently.

Interview Tips

Preparing for a Cold Rolling Supervisor interview can be daunting, but with the right approach, you can increase your chances of success. Here are some tips to help you ace the interview:

1. Research the Company and the Position

Take the time to research the company and the specific position you are applying for. This will help you understand the company’s culture, values, and goals, as well as the specific responsibilities of the role.

- Visit the company’s website and social media pages.

- Read industry publications and news articles.

- Talk to people in your network who work in the industry.

2. Practice Your Answers

Once you have a good understanding of the company and the position, take some time to practice your answers to common interview questions. This will help you feel more confident and prepared during the interview.

- Use the STAR method to answer behavioral questions.

- Prepare questions to ask the interviewer at the end of the interview.

3. Dress Professionally

First impressions matter, so make sure you dress professionally for the interview. This means wearing a suit or business casual attire.

- Choose clothes that are clean, pressed, and fit well.

- Avoid wearing strong fragrances or jewelry that could be distracting.

4. Be on Time

Punctuality shows respect for the interviewer’s time. Plan your route in advance and leave yourself plenty of time to get to the interview location.

- Factor in time for traffic and parking.

- If you are running late, call or email the interviewer to let them know.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Cold Rolling Supervisor interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.