Are you gearing up for a career in Cold Saw Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Cold Saw Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

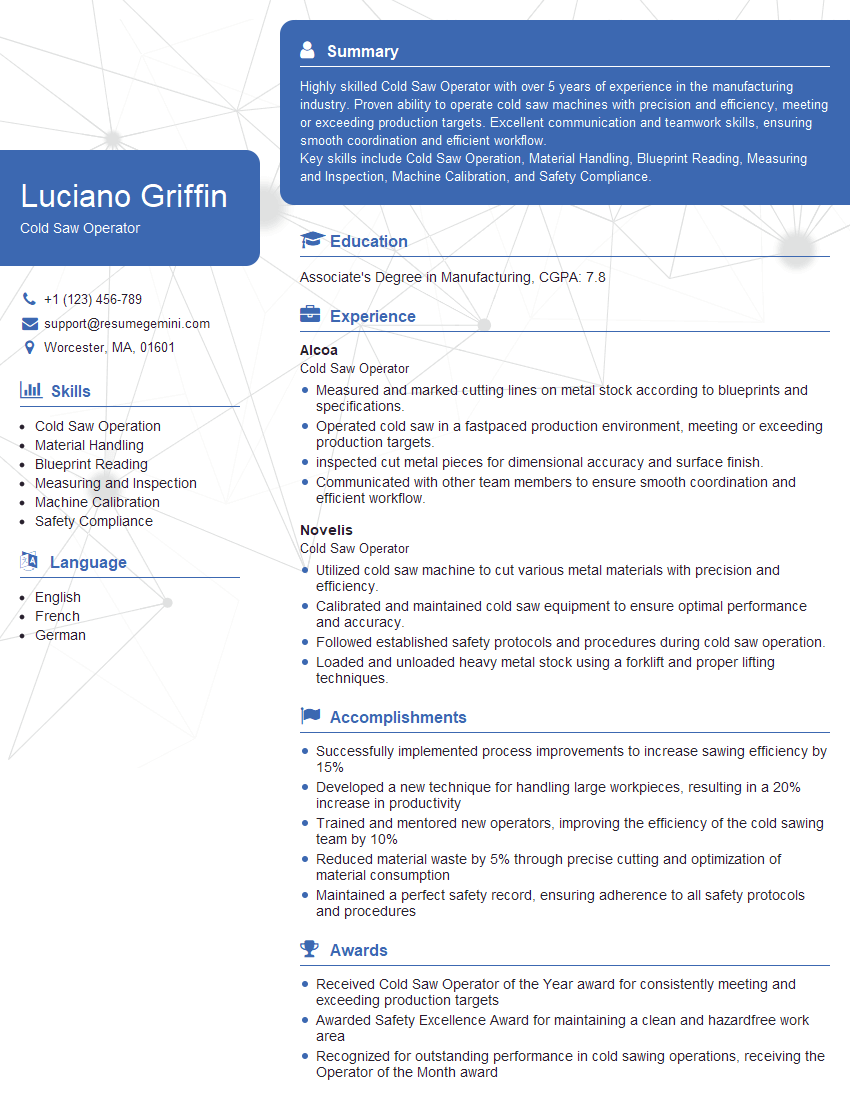

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cold Saw Operator

1. What are the different types of cold saws and their applications?

- Horizontal cold saw: Used for cutting large and heavy materials at a 90-degree angle.

- Vertical cold saw: Used for cutting smaller and lighter materials at various angles.

- Orbital cold saw: Used for cutting thin and delicate materials with a circular blade.

2. Explain the process of setting up and operating a cold saw.

Safety precautions

- Wear proper safety gear (gloves, safety glasses, hearing protection).

- Ensure the machine is stable and properly grounded.

Setting up

- Mount the saw blade and secure it properly.

- Adjust the blade height and speed according to the material being cut.

- Set the material stop to the desired length.

Operating

- Position the material on the table and secure it.

- Start the saw and slowly feed the material into the blade.

- Maintain a steady feed rate to ensure a clean cut.

3. How do you maintain and troubleshoot a cold saw?

- Regularly inspect and clean the blade and machine.

- Check the coolant system and replenish as needed.

- Lubricate moving parts and bearings.

- Blade vibration: Check for loose blade, improper tension, or dull blade.

- Poor cut quality: Check blade sharpness, feed rate, or material quality.

- Overheating: Check coolant levels, coolant flow, or motor overload.

Troubleshooting

4. What are the safety protocols for operating a cold saw?

- Always wear appropriate safety gear.

- Ensure the work area is clear of obstacles and debris.

- Inspect the saw before each use and report any defects.

- Never operate the saw under the influence of alcohol or drugs.

- Follow proper lockout/tagout procedures when servicing the machine.

5. How do you calculate the blade speed and feed rate for different materials?

- Consider the material’s hardness, thickness, and desired cut quality.

- Refer to cutting speed charts or manufacturer’s recommendations.

- Use the formula: RPM = (Cutting Speed in feet per minute) / (Blade Circumference in inches)

- Adjust the feed rate based on blade speed and material characteristics.

6. How do you measure and adjust the accuracy of a cold saw?

- Use a precision measuring tool (e.g., micrometer, caliper).

- Measure the cut length or angle to verify accuracy.

- Adjust the saw settings (e.g., blade height, stop position) as necessary.

- Perform regular accuracy checks to maintain precision.

7. What are the different types of coolants used in cold sawing and their advantages?

- Water-based coolants: Provide good cooling but can rust materials.

- Oil-based coolants: Offer lubrication and protection but are more flammable.

- Synthetic coolants: Combine the benefits of water-based and oil-based coolants.

8. How do you prevent burrs and chatter during cold sawing?

- Use a sharp blade with the appropriate tooth profile for the material.

- Maintain a steady and even feed rate.

- Ensure the saw is properly aligned and calibrated.

- Consider using high-pressure coolant to minimize friction.

9. What are the best practices for optimizing cold saw performance?

- Regularly inspect and maintain the saw.

- Use the correct blade for the material and application.

- Set up the saw properly and use the appropriate cutting parameters.

- Monitor the cutting process and make adjustments as needed.

- Follow manufacturer’s recommendations and observe industry best practices.

10. What is your experience with different types of cold saws and materials?

- List the types of cold saws you have operated (e.g., horizontal, vertical, orbital).

- Describe the materials you have cut (e.g., steel, aluminum, plastics, composites).

- Highlight any challenges you have encountered and how you overcame them.

- Emphasize your ability to adapt to different machines and materials.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cold Saw Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cold Saw Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Cold Saw Operators manage and operate cold saws, which are machines used to cut metal. They work in industrial settings, such as manufacturing plants, metal fabrication shops, and construction sites.

1. Operating Cold Saws

Cold Saw Operators are responsible for setting up, calibrating, and operating cold saws to cut metal according to specifications. They must ensure that the saw is properly adjusted and that the cutting parameters are correct to produce high-quality cuts.

- Loading and unloading metal bars or beams into the saw

- Selecting and installing the appropriate saw blade for the material being cut

- Adjusting the saw speed, feed rate, and blade tension

- Monitoring the cutting process and making adjustments as needed

2. Maintaining Cold Saws

Cold Saw Operators are also responsible for maintaining their saws to ensure they are in good working condition. This includes regular cleaning, lubrication, and inspection of the saw and its components.

- Cleaning and lubricating the saw’s moving parts

- Inspecting the saw blade for wear and tear

- Replacing the saw blade when necessary

- Performing minor repairs on the saw

3. Quality Control

Cold Saw Operators are responsible for ensuring that the cuts they make meet the required specifications and quality standards. They must inspect the cut pieces for accuracy, dimensions, and surface finish.

- Measuring the cut pieces to ensure they are the correct length

- Checking the cut surfaces for burrs or other defects

- Making adjustments to the saw or cutting parameters as needed to improve the quality of the cuts

4. Safety

Cold Saw Operators work in a potentially hazardous environment. They must follow established safety procedures and wear appropriate personal protective equipment (PPE) to minimize the risk of accidents.

- Wearing safety glasses, gloves, and other PPE

- Following lockout/tagout procedures

- Using proper lifting techniques

Interview Tips

Before the Interview

1. Research the Company and Position

Learn as much as you can about the company and the specific position you are applying for. This will help you understand the company’s culture, values, and what they are looking for in a candidate.

- Visit the company’s website

- Read the job description carefully

- Research the industry and the company’s competitors

2. Practice Your Answers

Take some time to practice answering common interview questions. This will help you feel more confident and prepared during the interview.

- Review the key job responsibilities

- Think about your skills and experiences and how they relate to the position

- Prepare examples of your work that demonstrate your qualifications

3. Dress Professionally

First impressions matter. Dress professionally for your interview. This shows that you respect the company and the interviewer.

- Wear a suit or business casual attire

- Make sure your clothes are clean and pressed

- Pay attention to your grooming

During the Interview

1. Be Confident and Enthusiastic

Confidence and enthusiasm are contagious. Make eye contact, smile, and speak clearly. Show the interviewer that you are excited about the opportunity.

- Maintain a positive attitude

- Be genuine and authentic

- Share your passion for your work

2. Listen Carefully

It is just as important to listen to the interviewer as it is to talk. Pay attention to the questions they ask and answer them thoroughly.

- Ask clarifying questions if you don’t understand

- Summarize your understanding of the question before answering

- Provide specific examples to support your answers

3. Ask Questions

Asking questions shows that you are engaged and interested in the position. It also gives you an opportunity to learn more about the company and the role.

- Prepare a few thoughtful questions to ask the interviewer

- Ask about the company’s culture, values, and goals

- Inquire about the specific responsibilities of the position

After the Interview

1. Send a Thank-You Note

Within 24 hours of the interview, send a thank-you note to the interviewer. This shows that you appreciate their time and consideration.

- Thank the interviewer for their time

- Reiterate your interest in the position

- Highlight your key qualifications

2. Follow Up

If you haven’t heard back from the interviewer within a week, follow up. This shows that you are still interested in the position and that you are professional.

- Call or email the interviewer

- Be polite and respectful

- Inquire about the status of your application

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Cold Saw Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.