Are you gearing up for an interview for a Cold Working Inspector position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Cold Working Inspector and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

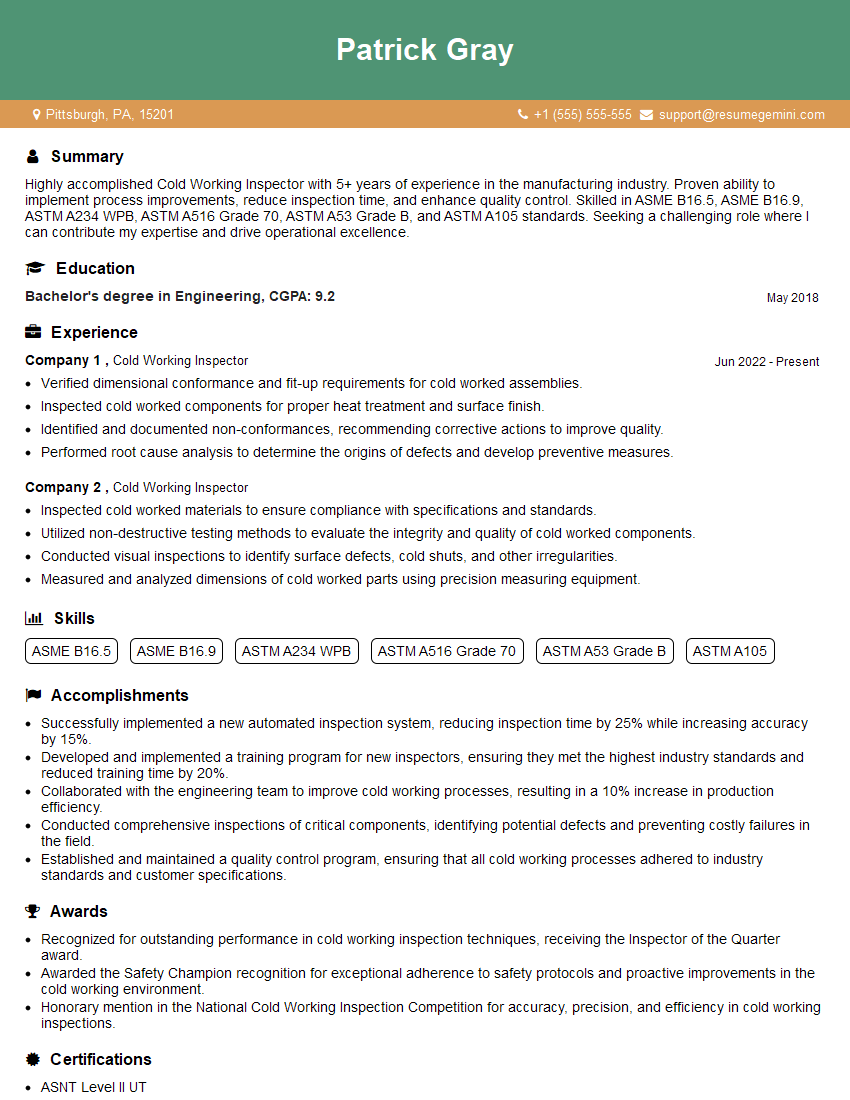

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cold Working Inspector

1. Explain the different types of cold working processes?

In cold working, metal is plastically deformed below its recrystallization temperature. Some of the common cold working processes are:

- Rolling: Passing metal between rollers to reduce its thickness or width.

- Drawing: Pulling metal through a die to reduce its cross-sectional area.

- Extrusion: Forcing metal through a die to create a desired shape.

- Forging: Shaping metal by hammering or pressing.

- Bending: Changing the angle of metal by applying force.

2. What are the advantages and disadvantages of cold working?

Advantages:

- Increases strength and hardness.

- Improves surface finish.

- Produces dimensionally accurate parts.

- No need for heating, saving energy.

Disadvantages:

- Can cause work hardening, making the metal brittle.

- Limited to certain materials and shapes.

- Can introduce residual stresses.

3. What equipment is used for cold working?

Various equipment is used for cold working, such as:

- Rolling mills

- Drawing machines

- Extrusion presses

- Forging hammers

- Bending machines

4. What are the quality control measures for cold worked products?

To ensure the quality of cold worked products, several quality control measures are employed:

- Dimensional inspection: Verifying the dimensions of the product meet specifications.

- Surface inspection: Examining the surface for defects such as scratches, dents, or cracks.

- Hardness testing: Measuring the hardness of the material to ensure it meets requirements.

- Tensile testing: Determining the tensile strength and elongation of the material.

5. Describe the role of lubricants in cold working?

Lubricants play a crucial role in cold working by:

- Reducing friction between the metal and tooling.

- Preventing galling and seizing.

- Improving surface finish.

- Extending tool life.

6. What is the importance of annealing in cold working?

Annealing is a heat treatment process that is used to soften cold worked metal and relieve residual stresses. It involves heating the metal to a specific temperature and then slowly cooling it.

7. Explain the difference between cold rolling and hot rolling?

Cold rolling is a process of rolling metal at room temperature, while hot rolling is done at elevated temperatures. Cold rolling produces a better surface finish and more precise dimensions, but it can only be used for thinner materials.

8. What are the safety precautions to be taken during cold working operations?

- Wear appropriate personal protective equipment (PPE).

- Inspect equipment before use.

- Follow proper operating procedures.

- Be aware of potential hazards.

- Report any unsafe conditions or practices.

9. What are the industry standards for cold working?

There are various industry standards for cold working, such as:

- ASTM A951: Standard Specification for Cold-Formed Welded and Seamless Carbon Steel Structural Tubing in Rounds and Shapes

- ASTM A1011: Standard Specification for Steel, Sheet and Strip, Hot-Rolled, Carbon, Structural, High-Strength Low-Alloy, High-Strength Low-Alloy with Improved Formability, and Ultra-High Strength

- ISO 9001: Quality Management Systems

10. Describe a challenging cold working project you have worked on?

(Provide a detailed description of a specific project, including the challenges faced and how they were overcome.)

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cold Working Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cold Working Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Cold Working Inspectors are responsible for ensuring that cold worked products meet the required standards and specifications. This includes inspecting raw materials, in-process products, and finished goods. They may also be responsible for developing and implementing quality control procedures, and for training and supervising other inspectors.

1. Inspect cold worked products

Cold Working Inspectors visually inspect cold worked products for defects, such as cracks, dents, scratches, and other imperfections. They may also use measuring tools, such as calipers and micrometers, to ensure that the products meet the required dimensions.

- Inspecting raw materials for defects

- Inspecting in-process products for defects

- Inspecting finished goods for defects

2. Evaluate product quality

Cold Working Inspectors evaluate the quality of cold worked products by comparing them to the required standards and specifications. They may also use testing equipment, such as hardness testers and tensile strength testers, to ensure that the products meet the required performance criteria.

- Evaluating the quality of raw materials

- Evaluating the quality of in-process products

- Evaluating the quality of finished goods

3. Develop and implement quality control procedures

Cold Working Inspectors may be responsible for developing and implementing quality control procedures. These procedures may include inspection methods, testing procedures, and acceptance criteria.

- Developing quality control procedures

- Implementing quality control procedures

- Maintaining quality control procedures

4. Train and supervise other inspectors

Cold Working Inspectors may be responsible for training and supervising other inspectors. This may include providing training on inspection methods, testing procedures, and acceptance criteria.

- Training other inspectors

- Supervising other inspectors

- Evaluating the performance of other inspectors

Interview Tips

Here are some tips for Cold Working Inspectors preparing for an interview:

1. Research the company and the position

Before your interview, take some time to research the company and the position you are applying for. This will help you to understand the company’s culture and values, and to tailor your answers to the interviewer’s questions.

- Visit the company’s website

- Read the job description

- Talk to people who work for the company

2. Prepare answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It is important to prepare answers to these questions in advance, so that you can deliver them confidently and concisely.

- Practice answering common interview questions

- Be prepared to provide specific examples of your experience

- Tailor your answers to the specific job you are applying for

3. Dress professionally and arrive on time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This shows the interviewer that you are serious about the position and that you respect their time.

- Dress professionally

- Arrive on time

- Be polite and respectful

4. Be yourself and be enthusiastic

It is important to be yourself and be enthusiastic during your interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Be confident in your abilities and let your personality shine through.

- Be yourself

- Be enthusiastic

- Show the interviewer that you are passionate about the position

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Cold Working Inspector, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Cold Working Inspector positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.