Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Collar Maker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

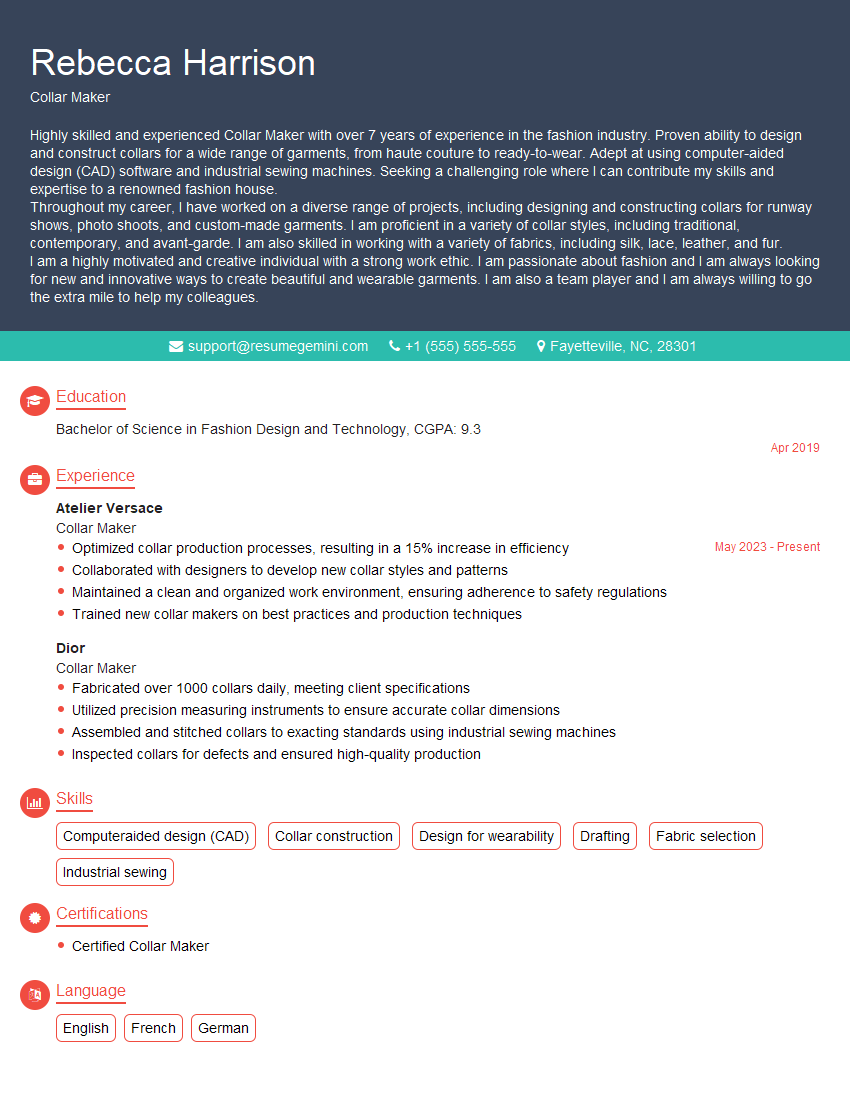

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Collar Maker

1. What are the different types of collar shapes and which type suits which face shape?

Collar shapes play a crucial role in complementing different face shapes. Here are some common types and their best matches:

- Round: Soft point collars or classic collars suit round face shapes as they elongate the face visually.

- Oval: Oval faces have more flexibility and can carry various collar styles, including pointed, spread, or semi-spread collars.

- Square: Pointed or wide-spread collars help soften the angles of square faces.

- Heart: Wide and open collars, such as spread or wingtip collars, balance the narrow chin of heart-shaped faces.

2. What are the distinctive markings of a well-crafted collar?

A well-crafted collar exhibits several key characteristics:

Fit and Comfort:

- Fits snugly around the neck without restricting movement.

- Stays in place throughout the day.

Construction Quality:

- Precise stitching and clean seams.

- Durable materials that resist wear and tear.

Style and Detail:

- Matches the shirt style and complements the wearer’s facial features.

- Displays attention to detail, such as interlining and hand-sewn elements.

3. What are the proper techniques for measuring and cutting collar fabric?

Accurate measuring and cutting are essential for collar construction:

- Measuring: Measure the circumference of the neck where the collar will rest.

- Collar Width: Determine the desired collar width and add seam allowance.

- Collar Height: Measure from the neckband to the top of the finished collar, including seam allowance.

- Cutting: Use sharp scissors and follow the precise measurements and grain lines.

4. How do you ensure the collar maintains its shape after washing and ironing?

Collar maintenance involves several steps:

- Interlining: Use a firm interlining material to support the collar and prevent curling.

- Stitching: Utilize close, even stitches to reinforce the collar structure.

- Washing: Machine wash on a gentle cycle with cold water and mild detergent.

- Drying: Hang or lay flat to dry, avoiding direct heat.

- Ironing: Iron on low heat with a damp cloth over the collar to protect the fabric.

5. What common problems arise during collar making, and how do you resolve them?

Some challenges in collar making include:

- Collar Rolling: Ensure proper interlining, close stitching, and correct grain line alignment.

- Collar Sticking Out: Adjust the collar’s fit and check the balance between the collar and the shirt body.

- Wrinkled Collar: Use a damp cloth while ironing and avoid over-ironing.

- Collar Not Sitting Flat: Check for uneven stitching, adjust interlining, and ensure the collar is symmetrical.

6. How do you stay up-to-date with the latest trends and techniques in collar making?

To stay current, I engage in the following practices:

- Industry Publications: Subscribe to fashion and sewing magazines to learn about new trends and techniques.

- Online Resources: Utilize online forums, workshops, and tutorials for up-to-date information.

- Fashion Shows and Exhibitions: Attend industry events to observe the latest designs and craftsmanship.

- Collaborations with Designers: Seek opportunities to collaborate with designers and exchange knowledge.

7. How do you assess the quality of different collar fabrics?

I evaluate collar fabrics based on the following criteria:

- Fiber Content: Consider the durability, wrinkle resistance, and breathability of different fibers.

- Thread Count: Higher thread counts indicate finer, stronger fabrics.

- Weave: Different weaves, such as poplin or twill, affect the fabric’s texture and drape.

- Finish: Check for special finishes, such as mercerization or sanforization, that enhance fabric quality.

8. What safety precautions are essential when working with collar-making tools and equipment?

Safety is paramount when using collar-making tools:

- Sharp Tools: Handle scissors, needles, and rotary cutters with care.

- Machinery: Follow operating instructions and ensure proper maintenance of sewing machines.

- Ergonomics: Maintain a comfortable work posture to prevent strain.

- Lighting: Adequate lighting prevents eye strain and improves accuracy.

- First Aid: Keep a first aid kit nearby for minor emergencies.

9. How do you maintain your workspace for efficient collar making?

An organized and efficient workspace is crucial:

- Declutter: Keep frequently used tools and materials within easy reach.

- Categorization: Store similar items together to avoid clutter.

- Regular Cleaning: Maintain a clean work area to prevent fabric contamination.

- Lighting: Ensure adequate lighting for precision work.

- Ventilation: Proper ventilation reduces dust and fumes.

10. How do you ensure the timely delivery of high-quality collars to clients?

To ensure timely delivery and quality:

- Planning: Establish realistic timelines and set clear expectations.

- Effective Communication: Maintain regular contact with clients to track progress.

- Quality Control: Implement rigorous quality checks at each stage of production.

- Contingency Plan: Prepare for unexpected delays and have backup plans.

- Customer Service: Address any client concerns promptly and professionally.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Collar Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Collar Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Collar Makers are responsible for creating and maintaining the collars of garments, ensuring they meet the desired specifications and quality standards. Their key job responsibilities include:

1. Collar Construction

Fabricating collars according to design specifications, using materials such as fabric, interfacing, and thread.

- Interpreting technical drawings and patterns to determine collar dimensions and shapes.

- Cutting and sewing collar pieces precisely, ensuring smooth seams and clean finishes.

2. Collar Shaping and Pressing

Shaping collars using techniques like steaming, pressing, and molding to achieve the desired form.

- Utilizing specialized equipment to create curves, angles, and other intricate shapes.

- Applying heat and pressure to set the shape and enhance the collar’s appearance.

3. Interfacing and Collar Support

Attaching interfacing materials to collars to provide structure and support, ensuring they retain their shape.

- Selecting appropriate interfacing materials depending on the collar’s design and fabric.

- Fusing or sewing interfacing to the collar pieces, ensuring a secure and durable bond.

4. Collar Finishing and Detailing

Adding finishing touches to collars, such as buttons, loops, and decorative elements, to enhance their aesthetics.

- Attaching buttons, buttonholes, and other embellishments according to design specifications.

- Inspecting completed collars to ensure they meet quality standards and customer requirements.

Interview Tips

Preparing thoroughly for a Collar Maker interview can significantly increase your chances of success. Here are some tips to help you ace the interview:

1. Research the Company and Position

Before the interview, take the time to research the company and the specific Collar Maker position you are applying for. Understanding the company’s culture, values, and products will demonstrate your interest and enthusiasm.

- Visit the company’s website to learn about their history, mission, and current projects.

- Review the job description carefully and identify the key skills and experience required.

2. Highlight Relevant Skills and Experience

Emphasize your relevant skills and experience during the interview. Be prepared to discuss your knowledge of collar construction, shaping, interfacing, and finishing techniques.

- Quantify your accomplishments whenever possible, using specific examples to demonstrate your impact.

- Explain how your previous experience has equipped you with the necessary skills to excel as a Collar Maker.

3. Practice Answering Common Interview Questions

Take some time to practice answering common interview questions related to the Collar Maker role. This will help you feel more confident and articulate during the actual interview.

- Prepare for questions about your technical skills, attention to detail, and ability to work in a fast-paced environment.

- Consider questions related to your experience with different fabrics, interfacing materials, and collar designs.

4. Be Enthusiastic and Professional

Throughout the interview, maintain a positive and enthusiastic attitude. Show the interviewer that you are genuinely interested in the position and eager to contribute to the team.

- Dress professionally and arrive for the interview on time.

- Be polite and respectful to everyone you encounter, including the receptionist and other employees.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Collar Maker interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.