Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Collator Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Collator Operator so you can tailor your answers to impress potential employers.

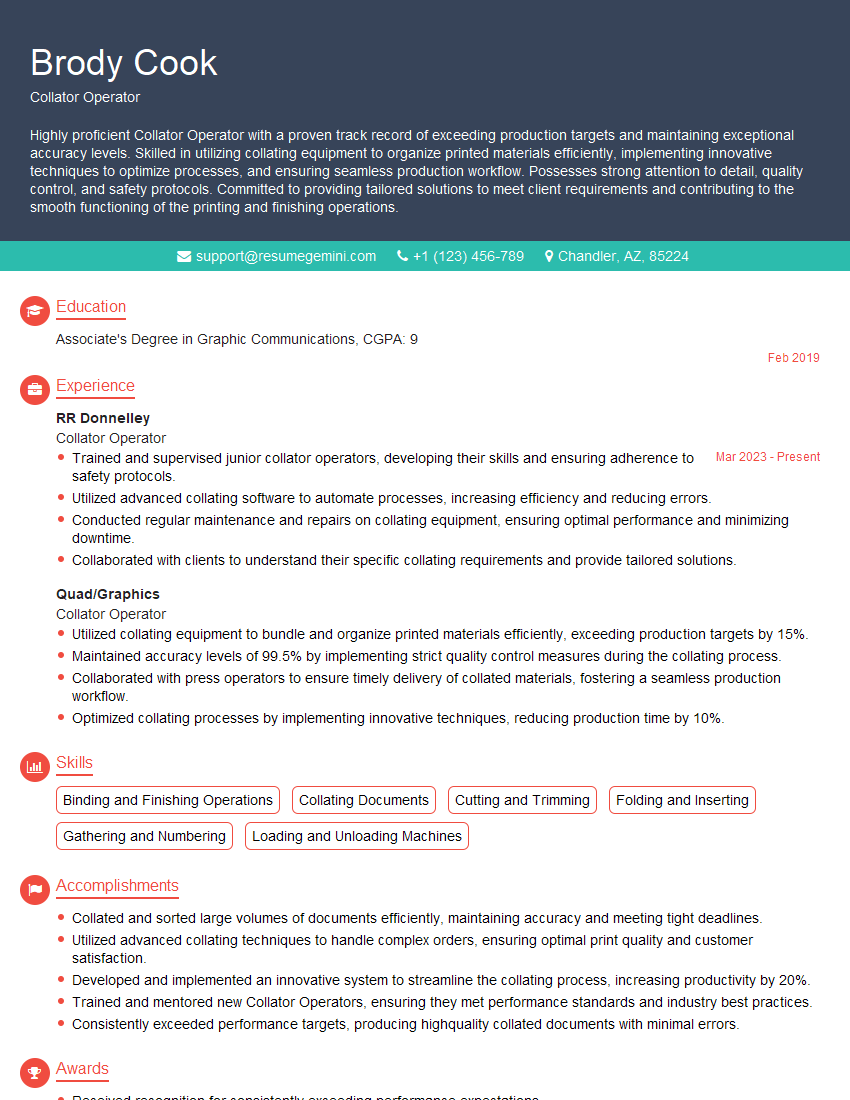

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Collator Operator

1. What is a collator and what are its functions?

A collator is a device used to collate or gather multiple sets of printed sheets into a single set in the correct order. Its primary functions include:

- Gathering printed sheets from multiple sources or feeders

- Combining them in the desired sequence

- Producing a complete set of collated documents

2. Describe the different types of collators and their applications.

There are several types of collators, each designed for specific applications:

- Saddle stitcher collators: Used for collating and saddle stitching booklets

- Perfect binder collators: For collating and perfect binding books

- Tower collators: For high-volume collating of large documents

- Online collators: Integrated with printers or copiers for inline collating

- Offline collators: Standalone devices used for post-press collating

3. Explain the process of collating documents using a collator.

The process of collating documents involves the following steps:

- Loading the printed sheets into the collator’s feeders

- Setting the collating sequence and desired output order

- Starting the collating process, which gathers and merges the sheets

- Monitoring the process and making adjustments as needed

- Unloading the collated sets

4. What are some common problems that can occur during collating and how can they be resolved?

Common problems during collating include:

- Misfeeds: Ensuring proper paper alignment and feeder settings

- Skipped sheets: Checking for paper jams and adjusting feeder tension

- Incorrect collation sequence: Verifying the collating settings and feeder order

- Incomplete sets: Confirming the number of sheets in each set and adjusting the collator accordingly

5. How do you maintain and troubleshoot a collator to ensure optimal performance?

Regular maintenance and troubleshooting are crucial for optimal performance:

- Routine cleaning: Removing dust and debris from feeders, belts, and sensors

- Feeder adjustments: Ensuring proper paper alignment and tension

- Sensor calibration: Verifying the accuracy of sheet detection sensors

- Software updates: Installing the latest software updates for improved functionality

6. What are the safety precautions that must be observed when operating a collator?

Safety precautions include:

- Keeping hands away from moving parts

- Wearing appropriate safety gear, such as gloves

- Not overloading the feeders

- Following proper lockout/tagout procedures before performing maintenance

7. How do you handle rush orders or unexpected changes in collating requirements?

To handle rush orders and changes effectively:

- Prioritizing tasks: Identifying the most urgent orders and allocating resources accordingly

- Communication: Coordinating with the production team to adjust schedules and meet deadlines

- Flexibility: Adapting quickly to changes in collating requirements

- Collaboration: Working with colleagues to ensure smooth transitions and minimize delays

8. How do you ensure the accuracy and completeness of collated documents?

To ensure accuracy and completeness:

- Checking source documents: Verifying the order and completeness of printed sheets before loading

- Setting the correct sequence: Programming the collator accurately to produce the desired order

- Visual inspection: Monitoring the collating process and visually inspecting output sets

- Quality control: Implementing appropriate quality control measures to identify and correct any errors

9. What software applications are you proficient in using for collating operations?

Relevant software applications include:

- Collator control software for managing collating processes

- Print management software for job tracking and scheduling

- Document management software for organizing and accessing source documents

10. How do you stay up-to-date with the latest collating technologies and best practices?

To stay current:

- Attending industry events: Participating in conferences and workshops

- Reading trade publications: Staying informed about advancements in collating technology

- Consulting with equipment manufacturers: Seeking technical guidance and product updates

- Networking with colleagues: Exchanging knowledge and sharing industry insights

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Collator Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Collator Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Collator Operators are responsible for operating and maintaining collating machines, which assemble and bind documents into booklets, reports, and other printed materials. Their primary duties include:

1. Machine Operation and Maintenance

Operate collating machines to gather, align, and assemble various printed documents, such as sheets, covers, and inserts.

- Monitor machine performance, troubleshoot issues, and perform routine maintenance to ensure smooth operation.

- Adjust machine settings to achieve optimal collation quality, including paper alignment, binding strength, and folding accuracy.

2. Material Handling

Load and unload materials into the collating machine, including paper, covers, and inserts.

- Inspect materials for defects or damage before processing.

- Maintain inventory of materials and request replenishment as needed.

3. Quality Control

Inspect collated materials for accuracy, completeness, and quality.

- Identify and correct any errors or defects.

- Ensure that finished products meet specified standards.

4. Safety and Compliance

Follow established safety procedures when operating machinery.

- Use proper personal protective equipment (PPE), such as safety glasses and gloves.

- Maintain a clean and organized work area.

Interview Tips

To prepare for an interview for a Collator Operator position, it is important to:

1. Research the Company and Position

Familiarize yourself with the company’s industry, products or services, and culture. Review the job description carefully to understand the specific responsibilities and requirements.

- Research common interview questions for Collator Operators and prepare thoughtful answers that highlight your skills and experience.

- Practice your answers aloud to improve your confidence and delivery.

2. Emphasize Relevant Skills and Experience

During the interview, focus on highlighting your abilities in operating collating machines, handling materials, and ensuring quality control. Provide specific examples of your experience in these areas.

- Quantify your accomplishments whenever possible, using metrics such as the number of documents collated per hour or the percentage of error-free products produced.

- If you have experience with different types of collating machines or materials, be sure to mention this.

3. Demonstrate Attention to Detail and Accuracy

Collator Operators must be meticulous and pay close attention to detail. In the interview, emphasize your ability to assemble documents accurately and efficiently, and to identify and correct errors.

- Share examples of how you have consistently met or exceeded quality standards in previous roles.

- Explain how you stay focused and maintain accuracy, even when working under pressure.

4. Show Enthusiasm and a Positive Attitude

Collator Operators often work in fast-paced environments and may be required to work independently. In the interview, convey your enthusiasm for the role and your willingness to work hard and contribute to the team.

- Be proactive by asking questions about the company, the position, and the team you would be working with.

- Express your interest in learning new skills and taking on additional responsibilities.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Collator Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!