Are you gearing up for a career in Colloid Mill Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Colloid Mill Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

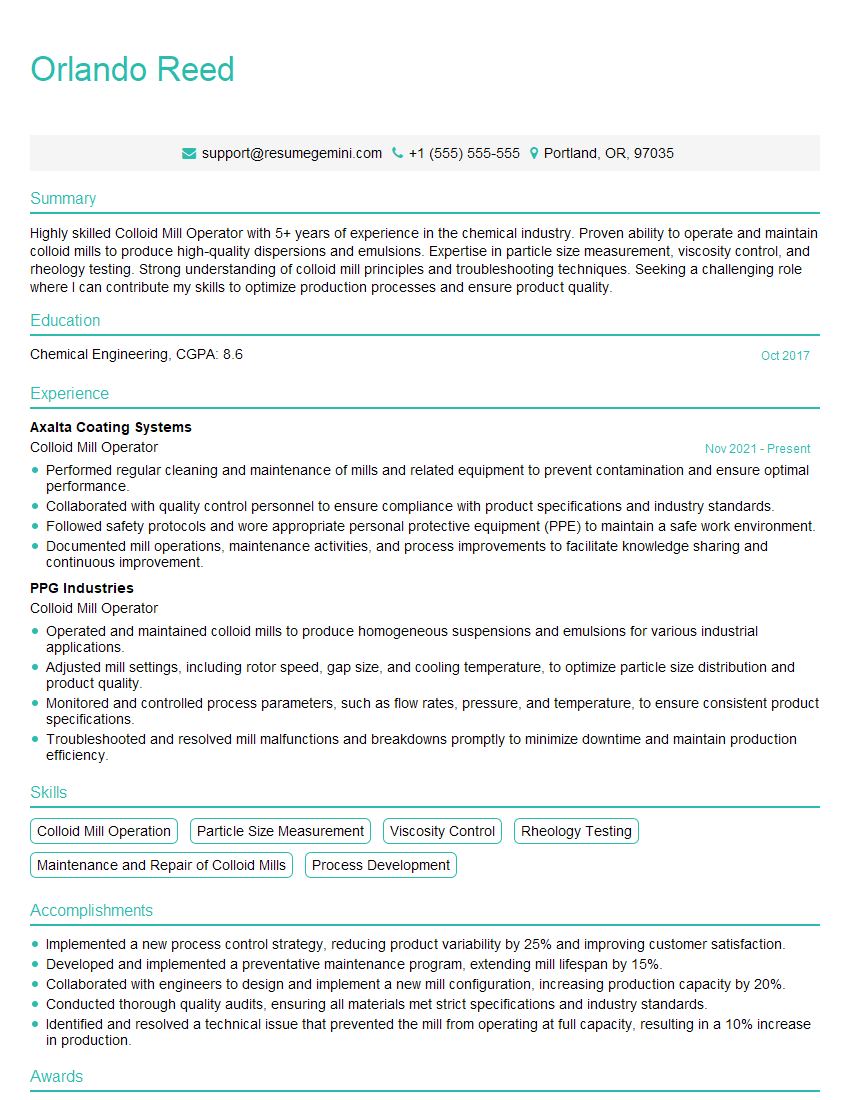

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Colloid Mill Operator

1. What are the key responsibilities of a Colloid Mill Operator?

- Operate and maintain a colloid mill to produce emulsions and dispersions.

- Monitor and adjust process parameters to ensure product quality.

- Clean and disinfect equipment to maintain a sanitary work environment.

- Perform routine maintenance and repairs on equipment.

- Work effectively as part of a team in a production environment.

2. Describe the different types of colloid mills and their applications.

Batch Colloid Mills

- Used for small-batch production of emulsions and dispersions.

- Consist of a cylindrical chamber with a rotating blade that grinds materials against a stationary blade.

Continuous Colloid Mills

- Used for large-scale production of emulsions and dispersions.

- Consist of a series of rotating and stationary blades that grind materials as they pass through the mill.

3. What are the important factors to consider when selecting a colloid mill?

- Product viscosity and particle size requirements.

- Production capacity and efficiency.

- Sanitary requirements.

- Maintenance and operating costs.

4. Explain the process of operating a batch colloid mill.

- Charge the mill with the desired ingredients.

- Start the mill and adjust the speed and grinding time to achieve the desired particle size.

- Monitor the temperature and pressure to ensure the product is not overheating or foaming.

- Discharge the finished product from the mill.

5. How do you clean and disinfect a colloid mill?

- Disassemble the mill and remove all product residue.

- Wash all parts with a detergent solution and rinse thoroughly with water.

- Sanitize all parts with an appropriate disinfectant and rinse thoroughly with water.

- Reassemble the mill and lubricate all moving parts.

6. What are the common problems that can occur with colloid mills and how do you troubleshoot them?

- Clogged screens: Clean or replace screens as needed.

- Overheating: Reduce mill speed or grinding time, or add cooling water.

- Foaming: Add an anti-foaming agent or reduce mill speed.

- Leaking seals: Replace seals as needed.

- Vibration: Check for loose bolts or unbalanced components.

7. What are the safety precautions that must be taken when operating a colloid mill?

- Wear appropriate personal protective equipment, including gloves, safety glasses, and earplugs.

- Never operate the mill with the covers or guards removed.

- Keep hands and loose clothing away from moving parts.

- Lock out and tag out the mill before performing any maintenance or repairs.

8. What is the importance of maintaining accurate records for colloid mill operations?

- To ensure product quality and consistency.

- To track process parameters and identify any deviations that could affect product safety or quality.

- To help troubleshoot problems and improve mill efficiency.

- To comply with regulatory requirements.

9. How do you stay up-to-date on the latest advancements in colloid mill technology?

- Attend industry conferences and trade shows.

- Read technical journals and articles.

- Consult with equipment manufacturers and suppliers.

10. What are your career goals and how do you see this position as a step towards achieving them?

- To develop my skills and knowledge in colloid mill operation.

- To contribute to the production of high-quality products.

- To advance my career in the manufacturing industry.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Colloid Mill Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Colloid Mill Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Colloid Mill Operators are responsible for operating and maintaining colloid mills, which are used to grind and disperse solids into liquids to create emulsions, suspensions, or solutions. Their key responsibilities include:

1. Operating Colloid Mills

Colloid Mill Operators are responsible for setting up, operating, and monitoring colloid mills. They must ensure that the mill is properly calibrated and adjusted to produce the desired product quality. They must also monitor the mill’s temperature, pressure, and flow rate to ensure that it is operating safely and efficiently.

- Set up and calibrate the colloid mill according to the desired product specifications.

- Start up and monitor the colloid mill, ensuring it operates smoothly and safely.

- Adjust the mill’s settings, such as speed, temperature, and pressure, to optimize product quality.

- Clean and maintain the colloid mill after each use to prevent contamination and ensure optimal performance.

2. Maintaining Colloid Mills

Colloid Mill Operators are also responsible for maintaining colloid mills. They must perform regular inspections and maintenance tasks to ensure that the mill is in good working order. They must also troubleshoot and repair any problems that may arise.

- Inspect and lubricate the colloid mill’s moving parts regularly.

- Replace worn or damaged parts as needed.

- Troubleshoot and repair any problems that may arise with the colloid mill.

- Keep records of all maintenance and repairs performed on the colloid mill.

3. Quality Control

Colloid Mill Operators are responsible for ensuring that the products produced by the mill meet the required quality standards. They must conduct regular quality checks and make adjustments to the mill’s settings as needed.

- Take samples of the product produced by the colloid mill and test them for quality.

- Make adjustments to the mill’s settings as needed to ensure that the product meets the required quality standards.

- Maintain records of all quality control tests performed.

4. Safety

Colloid Mill Operators must follow all safety regulations and procedures. They must wear appropriate personal protective equipment and operate the mill in a safe manner.

- Follow all safety regulations and procedures when operating the colloid mill.

- Wear appropriate personal protective equipment, such as gloves, safety glasses, and a hard hat.

- Operate the mill in a safe manner, avoiding any potential hazards.

Interview Tips

Preparing for an interview for a Colloid Mill Operator position can be daunting, but with the right preparation, you can increase your chances of success.

1. Research the Company and the Position

Before the interview, take some time to research the company and the specific position you are applying for. This will help you understand the company’s culture, values, and goals. It will also help you tailor your answers to the interviewer’s questions.

- Visit the company’s website to learn about their products, services, and history.

- Read industry news and articles to stay up-to-date on the latest trends and developments.

- Review the job description carefully and identify the key skills and qualifications required for the position.

2. Practice Answering Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice answering these questions in advance so that you can deliver your responses confidently and clearly.

- Use the STAR method (Situation, Task, Action, Result) to answer behavioral questions.

- Prepare examples of your skills and experience that are relevant to the position.

- Be prepared to discuss your knowledge of colloid mills and the industry.

3. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally for your interview. You should also arrive on time, as this shows that you are respectful of the interviewer’s time.

- Wear clean, pressed clothes that are appropriate for a business setting.

- Make sure your shoes are polished and your hair is neat.

- Arrive at the interview location 10-15 minutes early.

4. Be Enthusiastic and Positive

Interviewers are looking for candidates who are enthusiastic and positive about the position. This does not mean that you should be over-the-top, but you should convey that you are genuinely interested in the opportunity.

- Smile, make eye contact, and speak clearly.

- Be positive and enthusiastic about your skills and experience.

- Thank the interviewer for their time and consideration.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Colloid Mill Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!