Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Color Coater interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Color Coater so you can tailor your answers to impress potential employers.

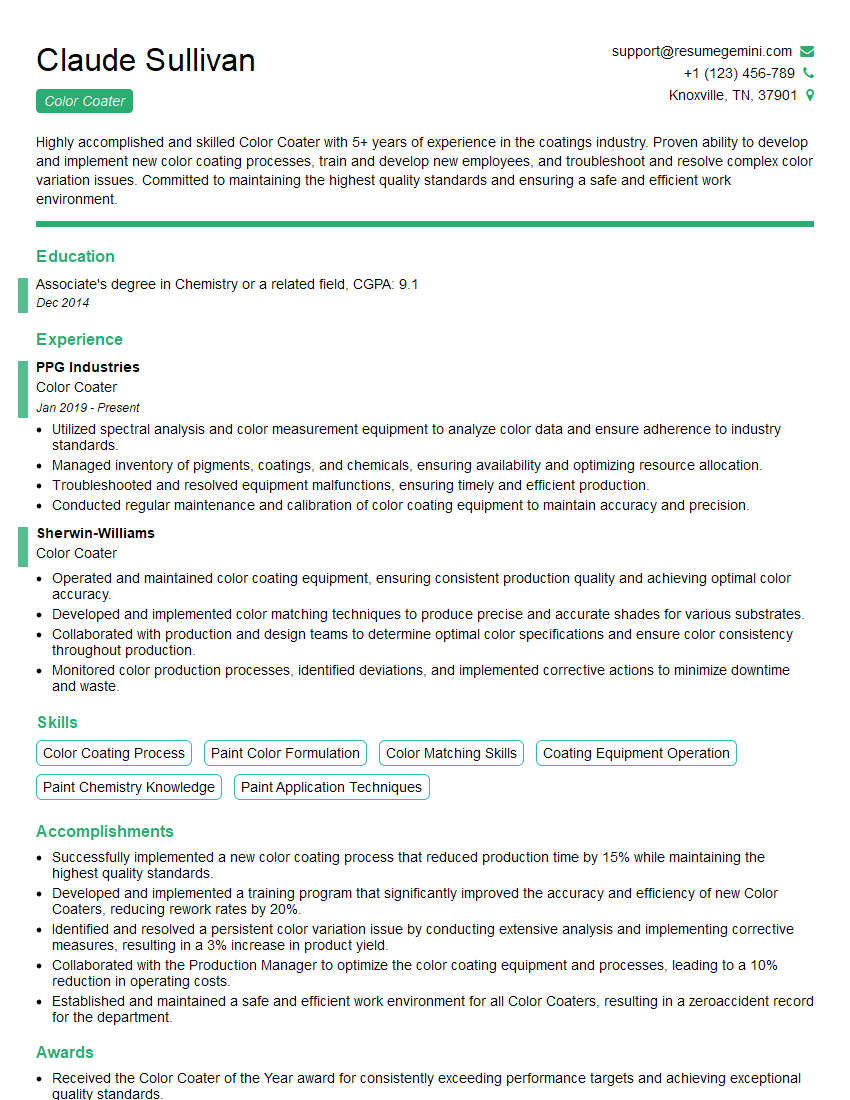

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Color Coater

1. Elaborate on the role of a Color Coater in the manufacturing process?

As a Color Coater, my responsibilities encompass several critical aspects of the manufacturing process:

- Applying a layer of colored coating to metal surfaces to enhance their appearance and protect them from corrosion and wear.

2. Describe the different types of coating materials used in the industry and their key characteristics?

Solvent-based coatings

- Advantages: Provide excellent durability, adhesion, and color retention.

- Disadvantages: High VOC emissions, slower drying time, and environmental concerns.

Water-based coatings

- Advantages: Low VOC emissions, faster drying time, and more environmentally friendly.

- Disadvantages: May compromise on durability and color retention compared to solvent-based coatings.

Powder coatings

- Advantages: Excellent durability, corrosion resistance, and a wide range of colors and finishes.

- Disadvantages: Requires specialized equipment for application, can be more expensive than liquid coatings.

3. Explain the process of color matching and how it ensures accurate color reproduction?

Color matching is a crucial aspect of our work. We use spectrophotometers to accurately measure the color of a sample and create a color formula that matches the desired shade. This formula is then used to mix and apply the coating, ensuring precise color reproduction.

4. Discuss the importance of surface preparation before coating and the techniques used to achieve a proper surface?

Surface preparation is paramount for ensuring the longevity and appearance of the coating. We meticulously clean and prepare the metal surface to remove dirt, grease, and any other contaminants. This involves techniques such as degreasing, phosphating, and abrasive blasting, depending on the specific material and application.

5. Explain the different methods of coating application and their advantages and disadvantages?

- Spray coating: Consistent and efficient, suitable for large or complex surfaces. However, it can generate overspray and requires proper ventilation.

- Dip coating: Provides a uniform coating on immersed surfaces. But, it’s limited to smaller parts and can be challenging to control the coating thickness.

- Roller coating: Ideal for flat surfaces, produces a smooth and even finish. However, it may not be suitable for intricate shapes.

6. What are the key quality control parameters in color coating and how do you ensure adherence to specifications?

We adhere to strict quality control measures by regularly monitoring coating thickness, adhesion, color accuracy, and surface finish. We use precision instruments and established testing methods to ensure that the coated products meet the desired specifications.

7. Describe the safety precautions and environmental regulations that need to be considered when working with coating materials?

Safety and environmental protection are paramount. We strictly follow all safety protocols, including wearing appropriate protective gear, ensuring proper ventilation, and handling hazardous materials responsibly. We also adhere to environmental regulations by minimizing waste, controlling emissions, and disposing of chemicals appropriately.

8. How do you stay updated with the latest advancements and trends in color coating technology?

I am committed to continuous learning and professional development. I regularly attend industry conferences, webinars, and workshops to stay abreast of the latest advancements in color coating techniques, materials, and equipment. I also actively explore technical articles and research papers to enhance my knowledge.

9. Describe a challenging project you encountered as a Color Coater and how you overcame it?

In a recent project, we encountered a complex color matching requirement for a large architectural structure. The desired color was extremely precise and difficult to achieve. I meticulously analyzed the sample, conducted multiple trial runs, and consulted with senior technicians. After several iterations, we successfully formulated and applied the coating, precisely matching the specified color and exceeding the customer’s expectations.

10. What are your strengths and weaknesses as a Color Coater?

- Strengths:

- Expert in color matching and formulation.

- Proficient in various coating application methods.

- Strong understanding of surface preparation techniques.

- Weaknesses:

- Limited experience with electroplating.

- Still developing expertise in automated coating systems.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Color Coater.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Color Coater‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Color Coater is responsible for applying a layer of color to metal sheets or coils in a manufacturing environment. They operate specialized equipment and ensure that the coating process meets specific quality standards.

1. Operate Coating Equipment

Operate and maintain coil coating equipment, including unwinding, pre-treating, coating, and rewinding machines.

- Monitor equipment performance and make adjustments as needed.

- Troubleshoot and resolve equipment malfunctions.

2. Prepare Metal Surfaces

Prepare metal sheets or coils for coating by cleaning, degreasing, and applying a primer.

- Inspect metal surfaces for defects and remove any contaminants.

- Follow established procedures for surface preparation to ensure proper adhesion of the coating.

3. Apply Color Coating

Apply a layer of color coating to the metal surfaces using rollers or sprayers.

- Control the thickness and consistency of the coating.

- Ensure that the coating meets the desired color and gloss specifications.

4. Inspect Coated Surfaces

Inspect coated metal sheets or coils for defects such as scratches, bubbles, or unevenness.

- Identify and record any defects or non-conformities.

- Take corrective actions to ensure the quality of the coated products.

5. Maintain a Clean and Safe Work Environment

Maintain a clean and organized work area.

- Follow safety protocols to minimize the risk of accidents or injuries.

- Dispose of hazardous materials properly.

Interview Tips

Preparing for an interview for a Color Coater position requires research, practice, and confidence. Here are some tips to help you ace your interview:

1. Research the Company and Position

Familiarize yourself with the company’s products, services, and culture. Research the specific role and its responsibilities.

- Visit the company’s website, social media profiles, and industry news articles.

- Understand the company’s values, mission statement, and goals.

2. Highlight Relevant Skills and Experience

Emphasize your skills in operating coil coating equipment, preparing metal surfaces, and applying color coatings.

- Quantify your accomplishments with specific examples and metrics.

- Use keywords from the job description to tailor your resume and interview answers.

3. Demonstrate Problem-Solving Abilities

Interviewers want to know how you handle challenges and solve problems. Share situations where you identified and resolved equipment malfunctions or ensured the quality of coated products.

- Use the STAR method (Situation, Task, Action, Result) to describe your problem-solving process.

- Focus on the outcomes and benefits of your actions.

4. Show Enthusiasm and a Positive Attitude

Convey your passion for the role and your commitment to delivering high-quality results.

- Express your interest in the company and the industry.

- Be confident and enthusiastic about your abilities.

5. Prepare Questions for the Interviewer

Asking thoughtful questions shows that you are engaged and interested in the position.

- Inquire about the company’s growth plans and future projects.

- Ask about opportunities for professional development and advancement.

Next Step:

Now that you’re armed with the knowledge of Color Coater interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Color Coater positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini