Are you gearing up for a career in Color Maker? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Color Maker and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

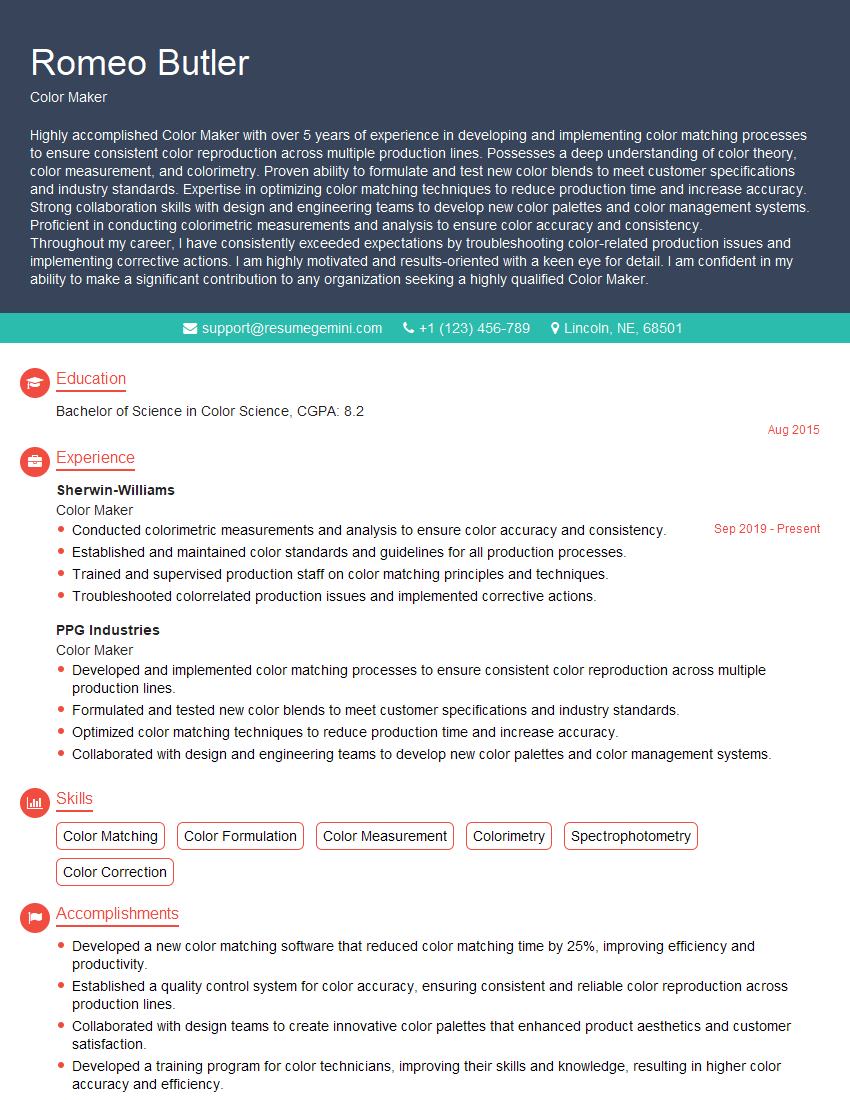

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Color Maker

1. Describe the process of creating a new color shade?

In creating a new color shade, the following steps are involved:

- Understanding the customer’s needs: This entails determining the desired color, application, and performance requirements.

- Research and experimentation: Exploring different pigments, resins, and additives to achieve the desired properties.

- Sample preparation and testing: Creating small batches of the new shade to evaluate its color, performance, and stability.

- Optimization and refinement: Fine-tuning the formulation based on test results to meet the desired specifications.

- Scaling up and production: Producing larger quantities of the new shade while maintaining its consistency and quality.

2. Explain the difference between organic and inorganic pigments?

Organic pigments:

- Derived from carbon-based materials such as dyes and synthetic chemicals.

- Typically offer vibrant colors and high transparency.

- May have lower lightfastness and chemical resistance compared to inorganic pigments.

Inorganic pigments:

- Derived from minerals or metal oxides.

- Provide excellent lightfastness, chemical resistance, and stability.

- Often less transparent and have a more opaque appearance.

3. What factors affect the performance of a color pigment?

Factors affecting color pigment performance include:

- Particle size and shape: Influences color intensity, transparency, and dispersion.

- Pigment concentration: Determines the depth and saturation of the color.

- Substrate: The surface on which the pigment is applied can impact its appearance and performance.

- Resin or binder: The material used to hold the pigment together affects its durability and adhesion.

- Environmental conditions: Factors such as sunlight, moisture, and temperature can affect the pigment’s stability and longevity.

4. How do you ensure color consistency in mass production?

Ensuring color consistency involves:

- Rigorous quality control: Establishing and adhering to strict standards for raw materials and production processes.

- Use of spectrophotometers: Utilizing precision instruments to measure and compare color values.

- Batch testing and approval: Sampling and testing each production batch to verify it meets specifications.

- Calibration and maintenance of equipment: Ensuring that all equipment used in color production is properly calibrated and maintained.

5. Describe the role of color matching in the manufacturing process?

Color matching plays a crucial role in:

- Product development: Matching new colors to existing product lines or customer specifications.

- Quality control: Ensuring that finished products meet color standards and customer expectations.

- Replicating existing colors: Matching colors for repairs, touch-ups, or historical preservation.

- Meeting industry regulations: Adhering to specific color requirements for industries such as food, pharmaceuticals, or automotive.

6. How do you keep up with the latest trends and innovations in color technology?

To stay abreast of industry advancements, I:

- Attend trade shows and industry conferences: Network with experts and learn about new products and techniques.

- Read technical publications and research papers: Stay informed about scientific advancements and industry best practices.

- Collaborate with suppliers and manufacturers: Explore new materials, technologies, and color trends.

- Participate in ongoing training and certifications: Enhance my knowledge and skills to align with industry standards.

7. Explain the concept of color gamut and its significance in color reproduction?

Color gamut refers to the range of colors that a device or system can produce or reproduce.

- Significance:

- Ensures accurate color representation across different devices and media.

- Helps avoid color distortion or mismatches when printing or displaying images.

- Allows for consistent color reproduction in various applications, such as design, photography, and video.

8. How do you handle color correction issues in production?

In case of color correction issues:

- Identify the cause: Determine if the issue is related to the substrate, pigment, or production process.

- Make adjustments: Modify pigment concentration, adjust equipment settings, or change raw materials as necessary.

- Conduct color matching: Compare the corrected color to the original specification or standard.

- Implement corrective actions: Implement changes in the production process to prevent similar issues in the future.

9. What safety precautions are essential in a color production facility?

Essential safety precautions include:

- Handling and storage of chemicals: Adhering to proper handling procedures, wearing protective gear, and following storage guidelines.

- Dust and fume control: Using ventilation systems and dust collectors to minimize exposure to airborne particles.

- Equipment maintenance: Regularly inspecting and maintaining equipment to prevent accidents and ensure safety.

- Training and education: Providing comprehensive training to employees on safe handling practices, emergency procedures, and hazardous materials management.

- Emergency preparedness: Establishing clear emergency response plans and procedures in case of spills, fires, or other incidents.

10. How do you stay motivated and maintain your passion for color making?

I maintain my motivation and passion for color making by:

- Appreciating the impact of color: Recognizing the power of color to evoke emotions, inspire creativity, and enhance our surroundings.

- Exploring new possibilities: Constantly researching and experimenting with different pigments, techniques, and applications to create innovative color solutions.

- Collaborating with others: Sharing knowledge, learning from peers, and working together to push the boundaries of color technology.

- Seeking feedback: Value feedback from customers and stakeholders to improve products and services while meeting their evolving needs.

- Staying informed: Keeping up with industry trends, attending workshops, and participating in professional development opportunities to expand my knowledge and skills.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Color Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Color Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Color Makers are responsible for the production and control of colorants, including paints, dyes, and inks. They work in various industries, such as manufacturing, textiles, and printing.

1. Developing and Maintaining Color Formulas

Color Makers develop and maintain color formulas to meet specific customer requirements. They use their knowledge of color theory and chemistry to create formulas that produce the desired colors.

- Analyze customer specifications and determine the required colorants and proportions.

- Experiment with different colorants and proportions to create the desired color.

- Document color formulas and maintain records for future reference.

2. Producing Colorants

Color Makers produce colorants in various forms, including liquids, powders, and pastes. They use specialized equipment to mix and blend raw materials to create the desired colorants.

- Weigh and measure raw materials according to the formula.

- Mix and blend raw materials using mixers and blenders.

- Control the temperature and other process parameters to ensure the production of high-quality colorants.

3. Testing and Evaluating Colorants

Color Makers test and evaluate colorants to ensure their quality and performance. They use specialized equipment to measure color and other properties of the colorants.

- Perform color matching tests to ensure the colorants meet customer specifications.

- Conduct performance tests to assess the durability, lightfastness, and other properties of the colorants.

- Analyze test results and make adjustments to the formulas as needed.

4. Troubleshooting and Problem Solving

Color Makers troubleshoot and solve problems related to the production and use of colorants. They use their knowledge and experience to identify and resolve issues that may arise.

- Troubleshoot production problems and make adjustments to the process as needed.

- Analyze customer complaints and provide technical support to resolve color-related issues.

- Develop and implement corrective actions to prevent future problems.

Interview Tips

Preparing adequately for an interview can increase your chances of success. Here are some tips to help you ace your Color Maker interview:

1. Research the Company and the Job

Researching the company and the job position demonstrates your interest and preparedness. Visit the company’s website to learn about their products, services, and culture. Read the job description thoroughly to understand the responsibilities and qualifications required.

2. Practice Your Answers to Common Interview Questions

Practice answering common interview questions, such as “Tell me about yourself” and “Why are you interested in this position?” Prepare specific examples from your experience that highlight your skills and abilities relevant to the job. Use the STAR method (Situation, Task, Action, Result) when answering questions to provide clear and concise responses.

3. Be Enthusiastic and Professional

Enthusiasm and professionalism can leave a positive impression on the interviewer. Express your genuine interest in the position and the company. Maintain eye contact, speak clearly and confidently, and be respectful of the interviewer’s time.

4. Prepare Questions to Ask the Interviewer

Asking thoughtful questions at the end of the interview shows your interest and engagement. Prepare a few questions related to the job, the company, or the industry. These questions demonstrate your curiosity and willingness to learn more.

5. Follow Up After the Interview

Following up after the interview is a courteous and professional way to show your continued interest in the position. Send a thank-you email to the interviewer within 24 hours, expressing your appreciation for their time and reiterating your enthusiasm for the job. Reiterate key points from your interview and highlight your qualifications once more.

Next Step:

Now that you’re armed with the knowledge of Color Maker interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Color Maker positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini